In order to further strengthen the treatment of the whole chain of plastic pollution and promote the "14th Five-Year Plan" white pollution control to achieve greater results, we have formulated the "14th Five-Year" Plastic Pollution Control Action Plan". The plan proposes to strengthen the standardization of plastic waste recycling and removal. In terms of residents' lives, some communities have increased the classification of garbage by households, and some communities have led everyone to learn basic plastic recycling skills.

The charter also proposes that each industry must increase the recycling of plastic waste, support the construction of plastic waste recycling projects, publish a list of enterprises that regulate the comprehensive utilization of waste plastics, and promote the large-scale, standardized and clean development of the plastic waste recycling industry. In addition, some relevant departments have accelerated the promotion and application of advanced and applicable technologies and equipment for the recycling of waste plastics, and encouraged the homogenization and high value-added utilization of plastic waste.

In this context, TENGDA has focused on the manufacture of plastic extruders for more than 10 years, and we are committed to developing new environmentally friendly extruders that can be used for plastic recycling.

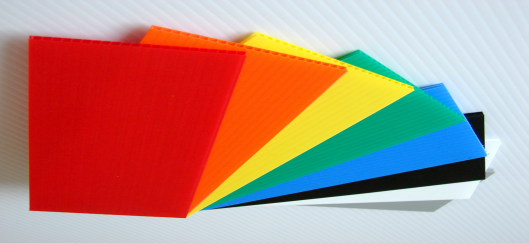

What materials can use for plastic recycling?

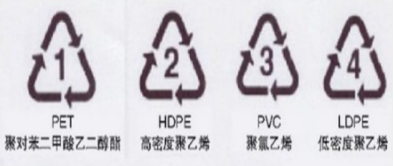

There are about 5 kinds of recycled plastics that we commonly use in daily life and industry, such as PET、LDPE、HDPE、PP、PVC.

1. PET

In life, it can be seen almost everywhere, such as mineral water bottles, carbonated beverage bottles, and food trays. Of course, the raw material of plastic bottles belongs to food-grade PET, but these plastic bottles are not resistant to high temperatures, so they cannot be used directly. In China, most plastic bottles are recycled and recycled, flowing to the textile industry, which is recycled into chemical fiber, PET fiber, polyester, non-woven fabrics, and made into household items such as blankets.

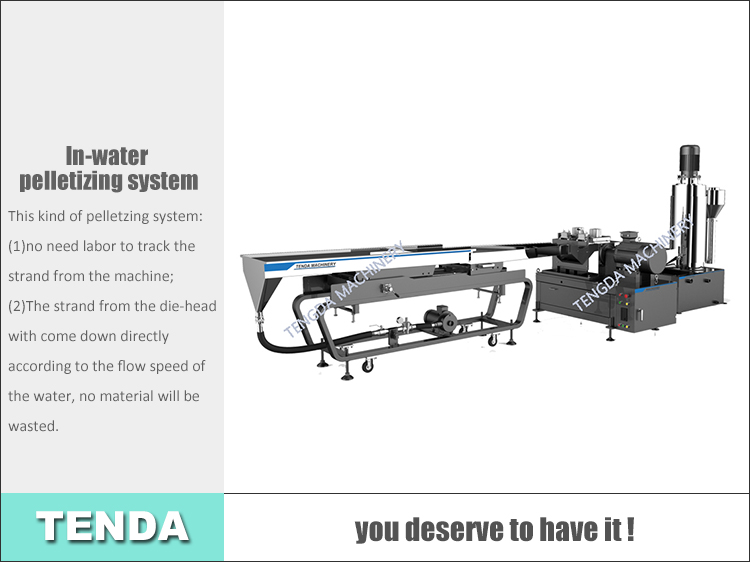

TENGDA also showed a unique style in this regard, developing and manufacturing a flushing twin-screw PET granulation production line. We are a professional group manufacturing twin screw extruder more than 10 years, our company has established the Twin screw Technology R&D Business Division with China North Industries Group. Our company specializes in the plastic blending modification.Compared with other factory, we are one that integrates industry and trade, so we have enough stock to ship at any time.

Its unit technical characteristics :

1. high viscosity, high output

2. No need for manual pulling, saving manual strength and reducing costs.

3. The pelleted parts and moving knives are less worn and have a longer service life.

4. The machine performance is more reliable, the operation is very convenient.

5. The machine assembly is very reasonable, the footprint is very small, and the space saving is saved.

|  |

2. HDPE

HDPE products are non-toxic, tasteless, odorless, and are milky white granules. It has good heat resistance and cold resistance, good chemical stability, high rigidity and toughness, good mechanical strength, dielectric properties, and good resistance to environmental stress cracking. Therefore, there are grades with lower fluidity with toughness and higher flow grades with process ability, which are often selected materials for production and processing. It is often used for extrusion packaging films, ropes, woven nets, fishing nets, water pipes, injection molding lower grade daily necessities and shells, extrusion blow molded containers and drain pipes.

3. PVC

PVC is a non-crystalline material, but also has high strength and excellent stability, and is not flammable, can resist the corrosion caused by climate change and other phenomena. It is a very good material, because of its high safety, so it can be seen everywhere in life. And it usually plays a big role in disposable medical equipment. PVC can be divided into soft PVC and hard PVC. Soft PVC is generally used in flooring, ceiling and leather. Hard PVC has good flexibility, easy to form, not easy to be brittle, non-toxic and pollution-free, long storage time, and it is common in building materials packaging.

4. HDPE

LDPE is a plastic material, it is suitable for various molding processes of thermoplastic molding processing, and the molding process ability is good. After LDPE is recycled and granulated by the extruder, the granules can be used to make plastic extruded bottles, plastic shopping bags, dry cleaning bags, bread bags. After recycling, it is remade into trash linings, shipping packages, and wood. But its main use is mainly divided into two categories: one is to make agricultural greenhouse film, to shield vegetables, melons and fruits from the wind and rain. The second category is small containers used for injection molding to make plastic.

5. PP

PP is a semi-crystalline thermoplastic, it has high impact resistance, mechanical properties are relatively strong, it is popular in foreign countries, is a green environmental protection material, and currently people support low-carbon environmental protection life in line. Its main uses are many, such as: hollow boards, turnover boxes, electronics industry packaging and other industries. And strictly speaking, PP plastic is not harmful to the human body, and has also become the darling of some plastic recycling manufacturing and processing plants.