What is the working principle of the twin screw extruder barrel? What affects the life of the barrel? The author interviewed the professional operators of the

twin-screw extruder barrel. For the barrel of the twin-screw extruder, many plastic machinery manufacturers and scientific research departments have conducted in-depth research on it, and have clear standards and evaluations for its working principle and process. However, for the twin-screw Extruder barrel, there are many places worth studying. First of all, the barrel of the twin-screw extruder has the extruder principle of a single-screw extruder: solid conveying, melting, pressurizing, and pumping, mixing, stripping, and devolatilization, but this is not the case. The study of twin-screw extrusion theory started late, coupled with its many types, complicated screw geometry, and complicated extrusion process, which brought many difficulties to the study. On the whole, the research on the barrel theory of twin-screw extruders is still in the initial stage. This is called 'skills more than science'. From the study of its extrusion process, the barrels of twin-screw extruders are roughly divided into three Two links: 1. The law of polymer state change during the extrusion process, the conveying principle, the truth and law of conveying and exhausting solid melt, and establish a mathematical and physical model to guide the design and extrusion of twin-screw extruders Optimization of the process. 2. It is necessary to clarify the actual state of the change of two or more polymers and materials during the extrusion process, the mixing form, the process of structural change, and the relationship between the final mixture and the performance. 3. As a twin-screw extruder, the internal relationship between the reaction process, speed, performance and screw configuration and operating conditions during extrusion reaction molding is established to establish a model to guide the reaction molding extrusion. So what is the development of the twin screw extruder barrel? According to the investigation of the development of twin-screw extruder: it was first successfully developed in Italy in the 1930s, and it developed rapidly in the late 1960s and early 1970s. The intermeshing counter-rotating twin-screw was developed with the development of RPVC products, and the intermeshing co-rotation was developed with polymer modification. The research of twin-screw extrusion theory cannot adapt to the development of applications, and a consensus has been formed worldwide. It has become a major problem in the industry and a new profit growth point in the future, which is placed in front of all plastic machinery industries. 5 major factors affecting the life of the barrel 1. Ordinary wear 2. Corrosion wear 3. High-strength wear (heavy wear zone) 4. Working conditions (temperature and pressure influence) 5. Other component gases such as moisture, air, oxygen, etc. in the cylinder

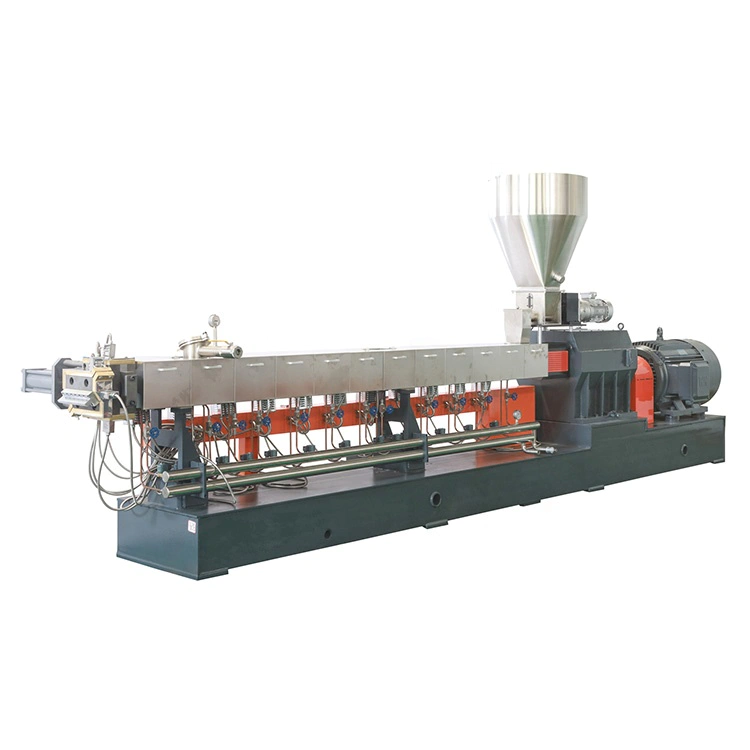

Everyone who has a extruder machine manufacturers wants it to look

plastic extruder machine manufacturers. However, in order to achieve that, it normally involves investing in a extruder machine manufacturers Application. Nanjing Tengda Machinery Co., Ltd. can offer you the best solution.

There is always a question of how to plastic

extruder machine manufacturers, but have you ever thought about the price point? Go to TENGDA Extruder Machine Manufacturers to get cost effective offer.

extruder machine manufacturers Application are primarily used for plastic extruder machine manufacturers.

Nanjing Tengda Machinery Co., Ltd. have significantly changed the way customers approach manufacturing. Application can still compete if we are willing to change the ways in producing.

Application is attracting a great positive feedback from the customers. And many of our clients are fully satisfied with it.