My knife is broken again!

In actual production, the underwater pelletizing equipment is prone to cutter damage, resulting in unqualified pellets, which not only increases the cost of cutter replacement, but also may cause customer quality complaints and cause certain economic losses.

Extending the service life of the Tengda cutter can not only ensure the appearance quality of granulation, but also save the material cost of the cutter, and at the same time reduce the number of stops of the Tengda extruder caused by the replacement of the cutter. Therefore, it is very necessary to study the factors affecting the service life of the Tengda cutter.

What counts as cutter damage?

Taking PP as an example, PP raw materials and additives are conveyed and kneaded by Tengda twin screws in the barrel of the Tengda extruder, pass through the template in a molten state, and are then granulated by a cutter in circulating water. The cutter performs underwater granulation at a certain speed, and the tightness of the contact between the cutter and the template is adjusted by the air pressure of the feed and the air to produce the pellets with qualified appearance.

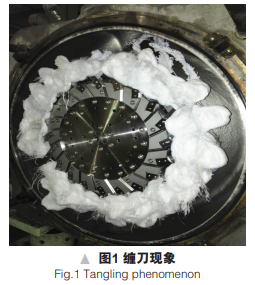

However, in long-term continuous production, different forms of cutter damage will occur, including cutter wear, cutter passivation and deformation, cutter breakage, etc. Among them, in normal production, the wear and passivation of the cutter is the most common phenomenon; when the production fluctuates, the cutter is prone to entanglement (see Figure 1), and cleaning the resin covering the cutter is easy to passivate and deform the blade . In order to prolong the service life of the Tengda cutter, special attention should be paid to the wear and tear of the cutter and the phenomenon of knife wrapping.

The Tengda wear amount of the cutter is proportional to the product of the contact pressure of the cutter and the rotational speed of the cutter. The Tengda wear amount of the cutter is measured by the reduction value of the cutter position. When the reduction value of the Tengda cutter position reaches 2mm, the Tengda cutter needs to be replaced. The reduction value of the Tengda cutter position can be reflected in a long time, and the Tengda cutter current can reflect the influence of the granulation process on the Tengda cutter wear in real time to a certain extent. Generally, when the current of the Tengda cutter is large, it means that the close contact between the Tengda cutter and the template increases the frictional resistance, or the higher rotational speed of the cutter increases the number of frictions, resulting in faster Tengda cutter wear per unit time. Therefore, when adjusting the granulation process, attention should be paid to the change of the Tengda cutter current.

1.Influencing factors of cutter damage

1.1 Tengda Pelletizing process

The contact pressure of the Tengda cutter is regulated by the feeding air pressure and the retracting air pressure. When the air pressure of the knife increases, the air pressure for the retraction decreases, the closer the contact between the cutter and the template, the greater the friction between the Tengda cutter and the template, the increase of the current of the Tengda cutter, and the increase of the wear of the Tengda cutter. The air pressure of the Tengda granulator entering the knife or the air pressure of the retracting knife fluctuates greatly, and the wear of the knife is accelerated.

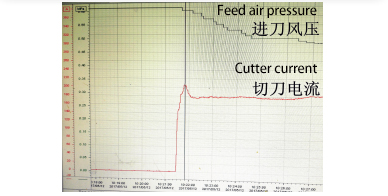

In addition, when the Tengda extruder is started, in order to make the Tengda cutter and the die plate closely contact without generating padding material, the initial feed air pressure is set to 0.6 MPa in manual mode, and then the feed air pressure is reduced by 0.01 MPa each time to When the feed air pressure is 0.48 MPa, the automatic mode is enabled; during the driving process, the maximum current of the cutter is as high as 206A, which is about 30A higher than the normal value (see Figure 2).

Figure 2

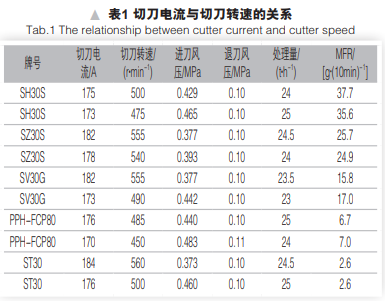

When the rotation speed of the Tengda cutter increases, the force of the Tengda pelletizing water on the cutter to press the template increases (its effect is equivalent to increasing the feed air pressure), and the number of frictions between the Tengda cutter and the template per unit time increases, and the Tengda cutter wears faster. It should be noted that when the Tengda cutter speed is too high, the cutter speed becomes the main factor affecting the Tengda cutter current. The Tengda cutter current increases obviously (see Table 1).

Table 1

1.2 PP grade

For different grades of PP, the physical properties are quite different. In general, the lower the MFR of PP, the greater the hardness of the molten material, the greater the friction on the cutting edge, and the easier it is to passivate the cutting knife. In actual production, brand switching is often carried out according to market demand, and transition materials will be generated during the process of cutting the brand.

The MFR of the transition material is always changing, so the Tengda pelletizing process (cutting water temperature, template temperature and cylinder temperature, etc.) needs to be adjusted accordingly, so that the hardness of the transition material passing through the cylinder and the template is uncertain. Due to the change of the hardness of the transition material, the cutter is subjected to repeated action of alternating stress, resulting in passivation of the Tengda cutter.

1.3 Polymerization/modification process

For the same grade of PP, the MFR fluctuates within a certain range due to the characteristics of the polymerization/modification process. When the MFR fluctuates greatly, it is also unfavorable to prolong the life of the Tengda cutter. In actual production, due to the influence of changes in process and raw materials, such as fluctuations in the amount of additives added, inconsistent feeding, uneven catalyst preparation, and low purity of raw materials, the uniformity and stability of product properties can be affected, which is not conducive to Tengda Knife protection during granulation.

The fluctuation of the post-processing section of PP polymerization can also have an adverse effect on the properties of the powder. For example, due to the fluctuation of the steam in the drying unit of the polymer raw material, the drying effect is not good, so that the raw material contains a certain amount of moisture, and finally the knife wrapping phenomenon occurs in the pelletizer.

1.4 Other

Equipment factors include the flatness of the Tengda cutter plate, the perpendicularity of the Tengda cutter shaft and the template, the flatness of the Tengda cutter surface and the material of the Tengda cutter.

The flatness of the Tengda cutter plate is not good, which leads to the inconsistent wear degree of the Tengda cutter. When some Tengda cutters are worn out and the pellets are unqualified, the Tengda cutter needs to be replaced in advance.

The poor verticality of the Tengda cutter shaft leads to non-parallel and uneven contact between the Tengda cutter and the template, and the rotating Tengda cutter is subjected to high-frequency alternating loads, resulting in abnormal overall wear or even Tengda cutter breakage. Increased crumbs.

The flatness of the cutting blade surface is not good, resulting in inconsistent wear of different parts of a single cutting blade. When part of the cutting blade is severely worn, the cutting blade needs to be replaced due to unqualified granulation.

The material of the cutter also has a great influence on the life of the cutter. The hardness of the cutter is too high, which leads to excessive wear of the template, which is prone to breakage of the cutter and shortens the service life of the cutter and the template. The hardness of the cutter is too low, resulting in excessive wear of the cutter, This results in an increase in irregular particles and finely diced powder; in addition, different manufacturers have different processing techniques for the material of the cutter. If the processing technique is improper, the microstructure of the cutter may be defective, forming a source of cutter breakage.

Because the dicing water is recycled and the additives contain weak acid components, the acid components dissolved in the dicing water continue to accumulate, resulting in increased acidity of the dicing water, which can corrode the cutting knife and make the cutting knife passivated. In severe cases, the blade is serrated and cannot be cut normally. grains, shortening the life of the cutter.

2. improve proposals

2.1 Tengda Granulation process

During normal production, the feed air pressure and the feed air pressure should be kept stable to avoid fluctuations. In order to ensure the quality of dicing, the actual production sometimes needs to maintain the feeding air pressure, and when the cutting current is large, the retracting air pressure can be slightly increased to reduce the cutter wear; it should be noted that the retracting air pressure should not be too high Large, so as to avoid normal dicing when the production process fluctuates, which will eventually lead to the occurrence of padding and knife wrapping.

In actual production, it is found that the two process parameters of low speed and high feed air pressure and high speed and low feed air pressure can produce resin particles with the same appearance. which process parameters. Generally, a lower cutter speed is used for granulation, and the process of using a high cutter speed is reduced.

In the process of starting up, high feed air pressure can increase the wear of the cutter, so frequent starting and stopping of the extruder should be avoided; at the same time, in the process of switching from manual mode to automatic mode, the feed air pressure should be gradually reduced. The setting value of the knife air pressure drops suddenly, so that the adhesion force of the cutting knife to the template is instantly reduced, and more molten material is easy to punch out of the template, which can lead to padding and wrapping of the knife. At the same time, the cutting knife and the template must be coated with silicone oil before driving, so that the molten material sticking to the knife can be thrown away from the cutting knife in time, thus avoiding the phenomenon of padding or even wrapping the knife.

2.2 Product grade

When dicing of the same brand, it is necessary to comprehensively adjust the temperature of the dicing water, the temperature of the template and the temperature of the cylinder to find the best combination of the three, so that the molten material has suitable dicing hardness, so as to avoid a large amount of molten material. The phenomenon of knife padding and knife wrapping caused by template. Therefore, when production fluctuates, the pelletizing process should be adjusted to increase the hardness of the molten material appropriately to ensure normal pelletizing.

When it is necessary to change the material for extrusion, the adjustment principle of the Tengda extruder process parameters can be summarized as "staring at the MFR, adjusting the parameters, and watching the particle shape". According to the change trend of MFR, adjust the temperature of the cutting water, the temperature of the template and the temperature of the cylinder, so that the molten material has a suitable cutting hardness, and the appearance of the pellet is good. If there is tailing material, snake skin material, etc., it is necessary to adjust the granulation process in time according to the actual situation to avoid the occurrence of knives and knives (Table 2). By lowering the temperature to increase the pelletizing hardness of the molten material, the pelletizing at the initial stage of the extruder is guaranteed to proceed smoothly, so as to realize the successful startup of the extruder during the cutting process.

2.3 Process stability

Control the stability of the front-end process and Tengda extrudert to ensure stable physical properties produced with the same formula, such as reducing the adverse effects caused by fluctuations in feed and uneven dispersion of additives and pigments, ensuring the purity of raw materials and keeping the physical properties within a narrow range keep it steady.

Minimize the switching operation of brands with a large MFR span. By optimizing the modification process, the production volume of transition material is reduced, so that it can quickly enter the qualified production stage, thereby reducing the adjustment time of the Tengda pelletizing process in the production of transition material, which is beneficial to the cutter Protect. In addition, ensure the normal operation of the material processing section and avoid wide fluctuations in the moisture content of the material.

2.4 Other

It is very important to ensure the installation accuracy of the Tengda cutter. The flatness of the cutter disc should be less than or equal to 0.01 mm, the perpendicularity of the cutter shaft and the template and the flatness of the cutting surface are less than or equal to 0.03 mm.

By sharpening the knife, the flatness of the cutting disc, the perpendicularity between the cutting shaft and the template, and the flatness of the cutting surface can be improved to match the template. Therefore, the sharpening quality should be improved, and the feed air pressure should be reasonably controlled. and sharpening time to avoid knife damage during sharpening.

The choice of cutter material is also very important. The hardness of the cutter should be lower than the hardness of the template to avoid the cutter from scratching the template; if the cutter frequently breaks, other high-quality cutters can be used or the cutter can be re-heated to eliminate the cutter. Defects in the texture of the material.

Regularly check the pH value of the pelletizing water. When the pH value is less than 7, open the fresh and refined water replenishment valve to make the pellet water overflow, so that the pelletizing water has a qualified pH value. Do not add industrial water and other water to the pelletizing water tank.

3. Summary of improvement plans

(1) To a certain extent, the current of the cutter can reflect the influence of the granulation process on the wear of the cutter in real time. When adjusting the pelletizing process, attention should be paid to the change of the cutter current.

(2) During normal production, the air pressure for feeding and retracting the knife should be kept stable to avoid fluctuations; comprehensively adjust the temperature of the cutting water, the temperature of the template and the temperature of the cylinder to ensure that the molten material has suitable cutting hardness.

(3) By optimizing the production process, the production volume of transition material is reduced when cutting the grade, and the physical properties of the resin are kept stable when the grade is the same.