plugging factor

Tengda extruder occurs during equipment parking, start-up, and normal production

If the product in the processing section and the discharge section is subjected to excessive thermal degradation during Tengda extruder shutdown, it may cause critical state precipitation or carbonization. This extreme thermal degradation of the product may lead to long-term problems during startup and production. Occurs within the template and will cause inevitable die hole blockage.

During the driving Tengda extruder process, if the flushing template is not in place, it will also affect the smoothness of the Tengda die hole. At the same time, the timing of the arrival of the product, the pellet water and the pelletizer blade at the die plate is critical to ensure a uniform product flow and to produce uniform pellets. Up to 30% of the template holes can "freeze" if the water flow to the template is started too early compared to the product time.

During Tengda extruder normal production, the plugging mainly occurs at the contact surface between the template and the cutting water. Due to the rapid temperature change and the influence of the Tengda cutting knife, the viscous-flowing polymer on this surface rapidly undergoes high elastic transformation and vitrification. change, and then constantly form plugging and punching. With the growth of time, some oligomers and impurities will be precipitated, forming a similar "hanging wall", which will reduce the flow area of the die hole. During Tengda extruder normal production, such hole plugging will generally not have an impact, but when the temperature changes to high melting point When referring to the product, this characteristic will directly affect the running state of the extruder due to the high fluidity of the high-melting product. Therefore, the temperature of the template and Tengda extruder pelletizing water plays a key role in preventing pore blockage. If the temperature of the Tengda extruder pelletizing water is too low, the temperature of the template will be reduced and the porosity will be increased. However, the temperature of the pelletizing water is too high, and the pellets cannot achieve the cooling effect, which may produce sticky material.

Influence of product characteristics on die hole plugging

low melting point products

Polypropylene itself is a mixture of various molecular weight molecules. Low melting means that there are large molecular weight parts in the product. These high molecular weight polymers have low melting index and are not easy to mix completely. When the Tengda extruder granulation output is low or the production fluctuates, especially the granulator When running in a low gear, it is possible to block the die hole due to the low discharge flow rate.

High Rong Finger Products

The flow of polypropylene melt in the cylinder can be regarded as the flow of viscous fluid, and the flow equation can be obtained according to fluid dynamics.

Q=K△P/μ(1)

In formula (1): Q is the flow rate of the extruder; K is a constant, which is related to the structure size of the screw; △P is the melt pressure difference; μ is the melt viscosity. When the extrusion flow rate is constant, as the melt index increases, that is, the melt viscosity decreases, the melt pressure difference will decrease accordingly. When the melt index is constant, with the increase of the flow rate, the melt pressure difference will increase accordingly.

The increase of melt pressure difference is conducive to the cleaning and cleaning of low-melting finger products and impurities adhering to the die hole, while the pressure of the high-melting product itself on the template is reduced, which is not conducive to its own scouring ability to the die hole. During production, special attention should be paid to the change of die pressure. Although the die pressure is mainly affected by the pressure drop at components such as load, melting finger, and screen changer, serious die hole blockage will directly lead to a rapid increase in die pressure.

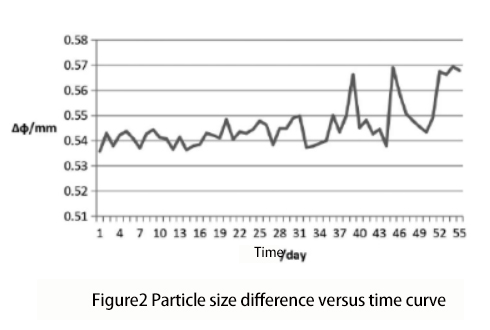

The influence of the production change plan on the blockage of the die hole

In the flexible production process of modified factories, it is often necessary to switch brands, which will cause changes in the production conditions of the Tengda extruder pelletizer: the polymer MFR changes greatly in a short period of time, causing the polymer flow rate in the Tengda extruder barrel to be inconsistent. All in turn lead to unstable discharge, and some die holes are "frozen" and blocked. When the controllable rheology (CRPP) scheme is converted to high-melt finger products, if the product is not mixed uniformly in the mixing section, part of the low-melt finger products will enter the template, and the temperature of the cylinder and template will decrease when converting to high-melt finger products. If it is too fast, the low-melting finger part cannot be completely melted, and it is easy to block the die hole.

Influence of load on die hole blockage

In the Tengda extruder production process, it is often necessary to adjust the production load. High load and low temperature will inevitably lead to incomplete mixing and block the die hole. Low load and high temperature will cause the material in the cylinder to extrude too fast at the template. It is easy to cause wrapping knives, pad knives, etc. The load adjustment should also avoid too fast and too large. Except for special needs in daily production, the adjustment load should not exceed 5% of the current load.

Influence of Tengda extruder Equipment Condition on Die Hole Clogging

The inner wall of the die hole itself is smooth, but under the action of external force, such as mechanical damage to the die hole caused by improper maintenance, or impurities caused by additive feeding, although the screen filter will filter out most of the impurities, but the subtle ones such as metal impurities After passing through the screen filter, it will also cause the mold hole to "hang on the wall" or "scratch". At the same time, when the screen filter is blocked, the pressure drop at the screen filter will increase, and the flushing pressure of the template will be reduced.

The law of the existence of plugging phenomenon

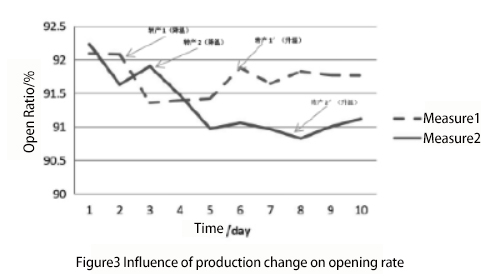

When part of the die holes are "frozen" and blocked, that is, the cross-sectional area of the die plate is reduced, resulting in a fast discharging speed of the remaining die holes. With the extension of the Tengda extruder running time, some die holes will be blocked or even completely blocked. Particle shapes also tended to change, tending to be elongated, with a large number of large and small particles.

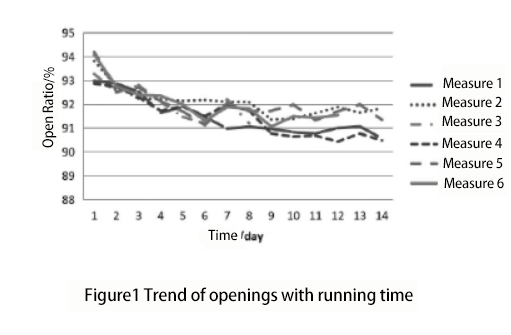

According to the picture data can be obtained:

(1) After the Tengda extruder starts normally, the blockage of the die plate will reach a relatively stable level within a certain period of time. In the case of no major adjustment operation, as the running time increases, some die holes will be blocked.

(2) Operations such as cooling down and replacing additives due to the need to change production will aggravate the blockage of the die holes for a short time. After the temperature rises, some die holes will be punched out.

In actual production, the operating state of the template should be analyzed in time according to the analysis results, and a solution should be established. For example, before switching to high-melting finger products, the temperature of the template and the temperature of the Tengda extruder pelletizing water should be increased in advance to improve the blockage of the die holes caused by various factors in the production stage of the low-melting finger products, and then reduce the temperature and switch to production according to the conversion plan.

Product Impact and Solutions

When the die hole is blocked, a large amount of fine particles will be produced, resulting in uneven particle size of the product and affecting the appearance of the product. During the transition to production and the production of high melting index products, the poor template may easily cause cutters, pad cutters, or even cause high torque reports of the pelletizer to interlock and stop, affecting production, long-term operation of the unit and device benefits.

In view of the above situation, the following measures can be taken:

(1) Properly increasing the temperature of the granulating cylinder and the template can enhance the flow performance of the material; before switching to high-melting products, the temperature of the template and the dicing water can be appropriately increased to melt or improve the blocked die holes.

(2) Properly increasing the load is conducive to the flushing of the die hole, but the temperature of the cylinder and the template must be appropriately increased to ensure complete mixing of the product. At the same time, if the torque fluctuation of the cutter has occurred, the load should be reduced in time and the speed should be high to avoid the high torque chain stop.

(3) Close the Tengda extruder pelletizing throttle valve to improve the mixing degree of the pelletizer, especially during the production of high melting index products, it is necessary to ensure that the products are fully kneaded.

(4) If the production is stopped for a long time, the temperature of the processing section must be lowered, especially in the area where the working temperature is very high, so as to prevent the products staying in the processing section from being excessively thermally degraded during the shutdown period.

(5) The template should be thoroughly inspected and cleaned before Tengda extruder driving. When flushing the template, make sure that the template has been rinsed before closing the trolley. During the driving process, in order to prevent the sudden temperature change of the contact between the pelletizing water and the template, the temperature of the template can be appropriately increased in advance.

(6) It is necessary to strictly control the impurities of the raw materials and the melting point of all the components of the subsequent additives. At the same time, the fluctuation of the additive amount will directly cause the poor hole of the die.

In actual production, the blockage of the template varies with the change of production conditions, especially when producing products with different characteristics, it is necessary to grasp the main contradiction leading to the instability of the extrusion unit, and determine the most Optimum process solution in order to improve product quality and achieve long-term Tengda extruder operation.