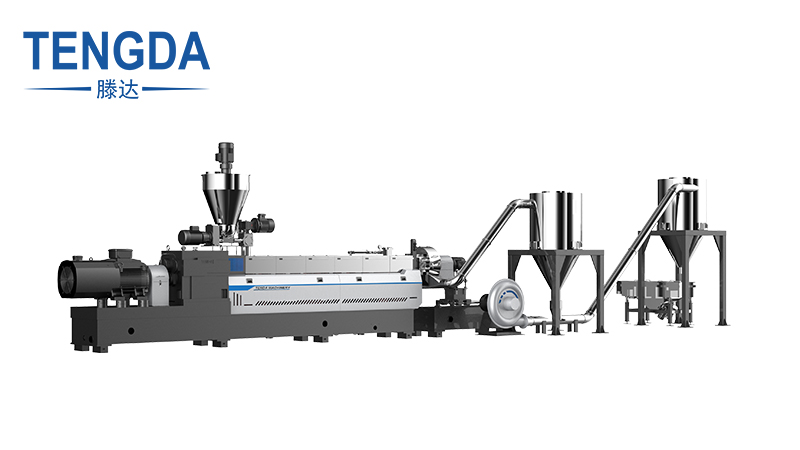

TSH-75P Twin screw plastic extruder with air-cooling hot-cutting system

This machine in this video is mainly used in producing PP/PE/EVA+CaCo3/Talc/TiO2/Carbon black masterbatch; Anti-flame or biodegradable granules making and many other materials. We are delivering the five twin screw production line to customer’s factory now.

This series twin screw extruder is researched and developed by the Twin Screw Technology Research and Development Business Division of the China North Industries Group Corporation Automation Research Institute. TSH-Plus series represent the most advanced standards of twin screw extruder in China, which produces the advantages of high-end twin screw extruder to the greatest extent in China

Unit Technical Characteristics:

1. With the development of 20-years experience,TSH series have become industry Standard equipment;

2. All screw and barrels adopt high wear-resistant materials;

3. High reliability transmission box, stable gearbox design;

4. Capacity is increased 10%-20%;

5. Energy-saving is increased by 5%-15%;

6. Free of debugging, fast installation;

7. Integrated design of vacuum water tank;

8. The total cooling of the equipment only needs to be connected to the import and export water, reducing the customer's installation cost, beautiful appearance, simple maintenance;

9. Overall reliability and quality stability lead domestically

Typical Configuration:

1. Deceleration, torque distribution integration, new structural design, enhanced safety margin, high precision hard tooth surface grinding, imported bearings and seals, independent forced lubrication cooling system and optional imported zero stress safety coupling;

2. The machine body adopts the reinforced design;

3. The Electric automatic control system is high-end imported instruments or touch screen system, and its main control components adopt the imported brands;

4. The barrels, screw elements and gearboxes of the main extruder are produced by CNC machining center.

Accessories Brand:

Motor: Imported Brazil “WEG” brand; Imported Germany “SIEMENS” brand; “WNA”brand;

Inverter: Imported Japan “TOSHIBA”、“FUJI” brand; Imported Switzerland “ABB”;

Switches: Imported France “Schneider” brand;

Temperature control instruments: Imported Japan “OMRON” brand;

PLC: Imported Germany “SIEMENS” brand(It’s designed by operation visualization and humanized parameter interface. PLC control system of TSH-75P twin screw extruder machine can provide historical operation information of the equipment, trace the cause of the failure, quickly find dynamic process data, correct it on time, optimize the production process and effectively save time and costs.);

Our twin screw extruder is used to produce various kinds of plastic granules.

Main Application:

1. Enforcing modification materials, such PE, EVA etc. + CaCo3, talc, TiO2, carbon black;

2. Biodegradable material masterbatch, such as PLA+starch+additives;

3. Anti-flame masterbatch, such as PE, EVA etc. +Sb2O2, Mg(OH)2, Al2(OH)2, etc.

Our company has obtained High-tech Enterprise and National High-tech Enterprice and passed ISO:9001 International Quality Management System Certification, CE Certification, TUV Certification, 17 utility model patents, 4 invention patents and 1 appearance patent.

Nanjing Tengda will continue to devote itself to the R&D and production of twin-screw extruders, and continuously improve products to meet customers’ requirements.