If there is no SOP, no standard, hurried installation and hurried disassembly, there will always be omissions of steps and standards. Once omitted, the screw thread components may not be removed, and they can only be destroyed and disassembled and then re-installed. , that's really half the effort. Establishing a standardized SOP can improve work efficiency and equipment utilization and reduce maintenance costs. So, how should standardized maintenance be done?

【Twin screw installation and removal 】

1. Installation of the screw

(1) Discrimination of screw direction: The twin screw itself is not divided into left and right, but for training and standardization, we deliberately set the left and right directions of the screw.

(2) Stand behind the main motor and look towards the barrel. The left hand is the left of the device, and the right hand is the right of the device.

(3) It is best to mark the screw with a marker or a lettering pen.

2. Disassembly of the screw

(1)Before disassembling the twin-screw, use PP or PE to clean the barrel with cleaning material. If the customer has oil additives, they can be cleaned with oil;

(2)Please remove the sensor in contact with the material;

(3)After removing the barrel "8-0", it is best to use a copper shovel to clean the remaining material;

(4)Using the tool for installing the screw, follow the reverse steps of installation to remove the screw. (Before removing the screw, be sure to turn off the power and lock it out)

(5) If you want to replace the screw block combination, you can loosen the screw head half a turn to one turn before the twin screw has not taken out the barrel, and then continue to loosen (connecting sleeve) in the maintenance room;

(6)If the screw is difficult to clean, it is necessary to put the screw into the barrel and heat it before cleaning.

【Leveling and centering of the extruder】

1. 5 datum planes

The gearbox has two datum planes, horizontal and vertical, at one corner; but not all gearboxes have them. If there is none, the end face of the connecting body connecting the gearbox with the first barrel can be selected as the datum plane.

• Process direction of the inner surface of the barrel of the discharge port

• Process flow direction on the inner surface of the exhaust port barrel

• Process direction of the last barrel surface

• The direction of the end face of the last section of the barrel

Check the adjustment base adjustment block (or the foot cup adjustment base)

Generally, we require the level of the equipment to be 0.1mm/m

2. Alignment of gearbox and motor

Please refer to the instruction manual, the pneumatic clutch needs to be provided with compressed air before it can be aligned

• It is recommended that 52 machines and above be used for alignment;

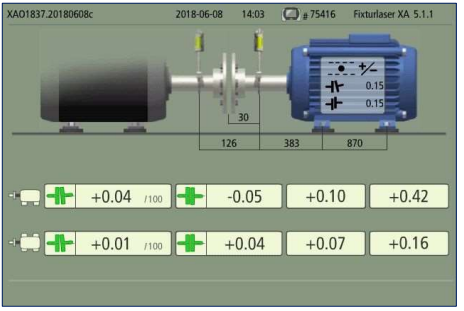

• Centering is divided into cold centering and hot centering, cold centering is performed before starting up, and the equipment is stopped for hot centering after running for 24 hours;

• Generally, center the left and right first, and then the upper and lower center. Considering the change of the pressing amount when the motor is finally pressed, try to let the motor rise a little (about 0.02-0.04mm change), depending on the size of the equipment.

• After the alignment is completed, mark the position where the motor base screw is fixed and adjusted with a marker pen, which is convenient for future inspection and pre-maintenance

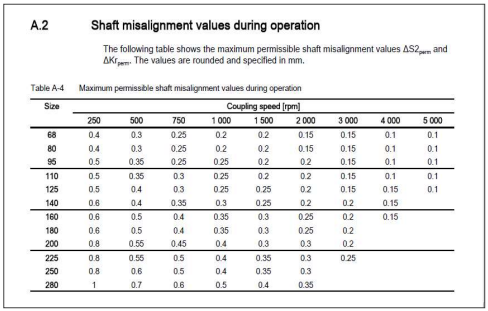

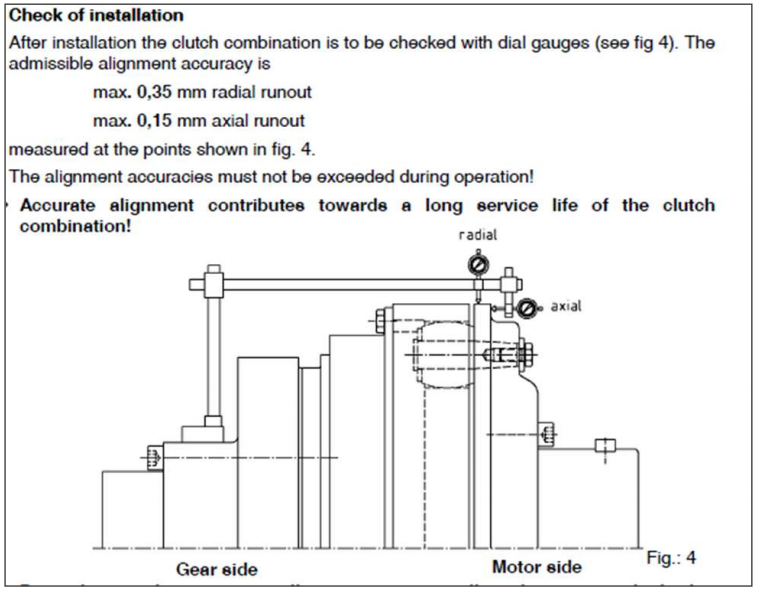

3. According to the centering requirements of the mechanical clutch, use the centering instrument to center

4. According to the centering requirements of the pneumatic clutch, use the centering instrument to center

、

、

【Check items before starting】

1. Lubrication - Apply anti-seize agent MoS2

• All connection setscrews, equipment, barrel, die connections

• Exhaust port, vacuum port, side insertion port, plug

• Gaskets for vacuum ports, copper pads for exhaust ports

• Twin screw head, twin screw connection sleeve

• Y-strainer

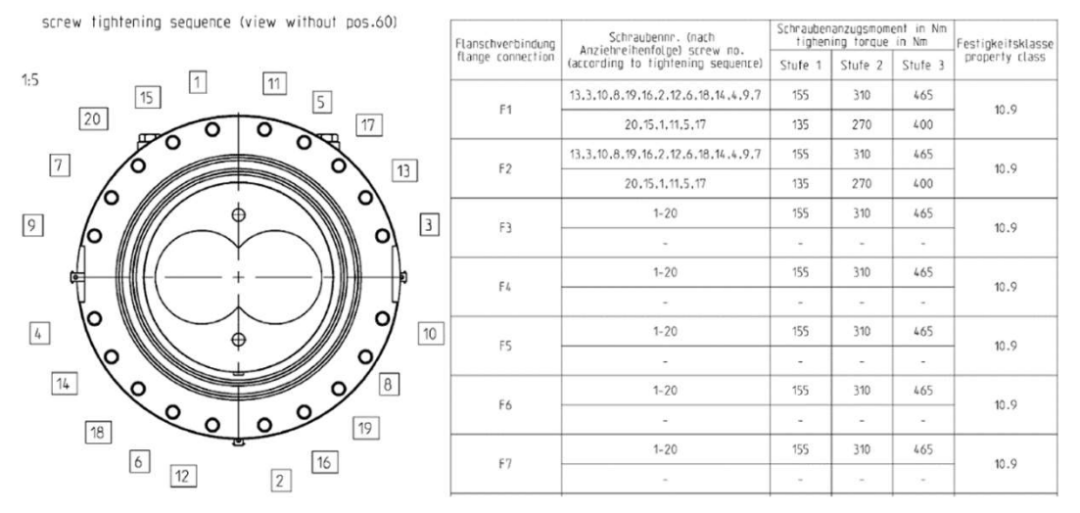

1. bolt tightening

• After all barrel heating plates are cold tightened, tighten again after the production operating temperature has been reached

• The tightening of the die head, die and barrel should be performed in steps and at different temperatures according to the torque requirements of the manual.

Key points: the die head and barrel, the screw head must be tightened with a torque wrench!

In the actual production process, many extruder failures are caused by the lack of careful and thorough daily maintenance work, and the key to daily maintenance work is to establish a standardized and standardized operation process and implement it strictly in accordance with this standard. To ensure the normal operation of the extruder, the most important thing is to form a set of standardized SOP to improve work efficiency and equipment utilization. This reduces downtime and maintenance costs.