A Beginner's Guide to Operating a Twin Screw Extruder Machine

A Beginner's Guide to Operating a Twin Screw Extruder Machine

Twin screw extruders are machines used to mix, compress and extrude different types of materials. They are commonly used in the plastics, food, and pharmaceutical industries. The use of twin screw extruders in industrial processes is gaining popularity through the years, thanks to their cost-effectiveness, precision, and flexibility.

If you are a beginner in the world of twin screw extrusion, you may find it overwhelming to operate this complex machine. However, with the right training and guidance, you can master the art of twin screw extrusion quickly. In this article, we will provide you with a beginner's guide to operating a twin screw extruder machine:

1. Understand the Parts and Functions of a Twin Screw Extruder

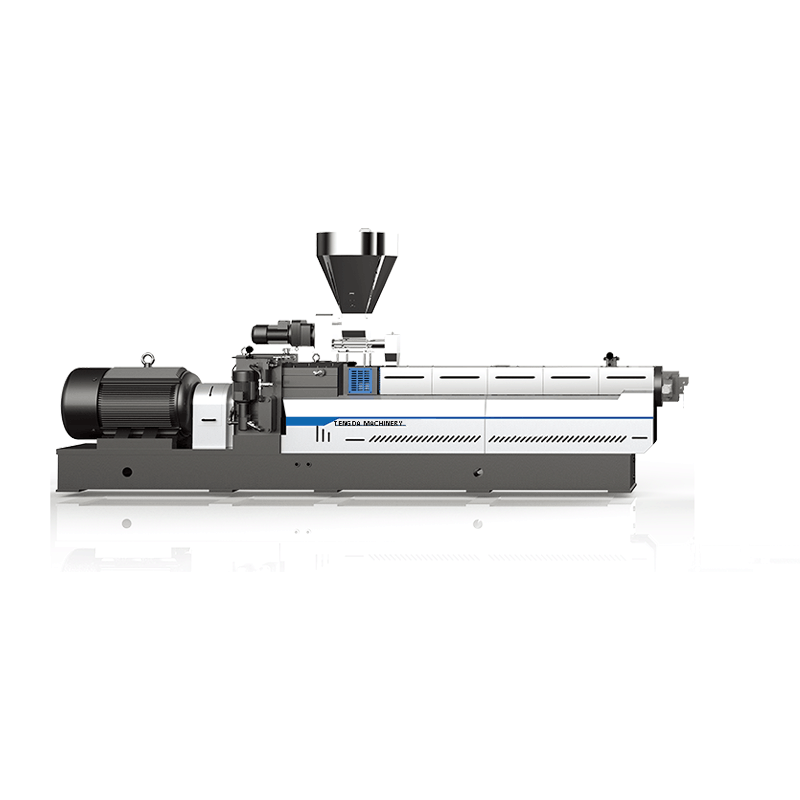

Twin screw extruders have several parts that work together to achieve the desired outcome. Understanding these parts' functions is essential for you to operate the machine effectively. The major parts of the twin screw extruder include feed hopper, barrel, extruder screws or shafts, die, and output section.

The feed hopper is where you pour the material to be extruded. The barrel is the main body of the machine, and this is where the screws or shafts are located. The extruder screws rotate in opposite directions, which pulls the materials through the barrel, compressing and mixing them. The die is where the final product takes its shape. The output section is where the final product is collected.

2. Familiarize Yourself with Different Twin Screw Extruder Configurations

Twin screw extruders come in different configurations depending on the materials type, throughput capacity, and product characteristics. The common types of twin screw extruders include co-rotating and counter-rotating extruders. Co-rotating extruders have screws that rotate in the same direction, while counter-rotating extruders have screws that rotate in opposite directions.

Specialized twin screw extruders are available for specific applications such as hot melt extrusion, reactive extrusion, and vented extrusion. Understanding the different twin screw extruder configurations available is essential to select the most appropriate machine for your specific application.

3. Prepare Your Materials for Extrusion

Preparing your materials for extrusion is essential for you to achieve high-quality products. The material's particle size and consistency affect the mixing and compressing during the extrusion process. Materials that vary in particle size and consistency may cause blockages in the extruder, affecting production efficiency.

Before starting the twin screw extruder, ensure that you have thoroughly cleaned the machine and components. It would help if you also ensured that the material you want to extrude is free from moisture and contaminants. Properly drying the material may involve different techniques such as vacuum or hot air drying.

4. Understand the Extrusion Process and Monitor Performance

The extrusion process involves several stages and is critical in determining the final product's properties. It would be best if you started by setting the barrel temperature, screw speed, and throughput rate. The barrel temperature should be appropriate for the specific material to prevent thermal degradation.

During the extrusion process, you should monitor the machine's performance to detect any abnormalities that may affect production efficiency. Monitoring parameters such as barrel temperature, screw speed, torque, and pressure can help you detect any deviations.

5. Troubleshoot Common Problems during Twin Screw Extrusion

Most twin screw extruders experience problems such as screw slippage, die swell, and barrel temperature inconsistencies. Knowing how to troubleshoot such problems is essential in ensuring that your production runs smoothly.

Screw slippage occurs when the extruder's torque limit is exceeded, resulting in slipping and reduced production efficiency. Die swell occurs due to excessive pressure causing the material to expand after leaving the die. Barrel temperature inconsistencies may cause production variability, affecting product quality.

In conclusion, operating a twin screw extruder machine can be challenging for beginners, but with the right guidance, you can quickly get the hang of it. Familiarizing yourself with the parts and functions of the machine, understanding the different configurations available, preparing your materials, and monitoring the extrusion process are some of the tips that can help you achieve successful extrusion.

Look at the trends, both economic and consumer, for indications on your Nanjing Tengda Machinery Co., Ltd.'s staying power.

Nanjing Tengda Machinery Co., Ltd.’s goal is to achieve customer satisfaction through excellence in design, supply chain management, manufacturing and repair solutions.

Our company specializes in manufacturing Application mainly plastic extruder machine manufacturers.