A brief introduction of the twin-screw plastic granulator

Twin-screw plastic granulator product introduction:

1. Gearbox

1) The deceleration and torque distribution parts are integrated into one, and the structure is compact;

2) Needle roller bearings, radial bearings for bearing deceleration torque distribution system

3) The gears are made of good alloy materials, and the precision is manufactured according to the ISO1328-1995 cylindrical gear precision. All the gears are made of carburized and hardened tooth surfaces. The tooth profile of the gear is trimmed by special grinding software to ensure the gear strength, uniform tooth load, high strength, low noise and low vibration;

2. Twin-screw plastic granulator screw:

1) The screw is a building block structure;

2) Mandrel material: 40CrNiMoA, the threaded element and the mandrel are involutely connected; high strength, large load bearing, easy disassembly and assembly;

3) The material of the threaded element is good high-speed tool steel W6MO5CR4V2, which is heat-treated by high-temperature vacuum quenching;

4) Overall hardness: HRC60-64;

5) The connection of the screw head and the parallel cap is an anti-tooth connection to ensure that the connection is tight.

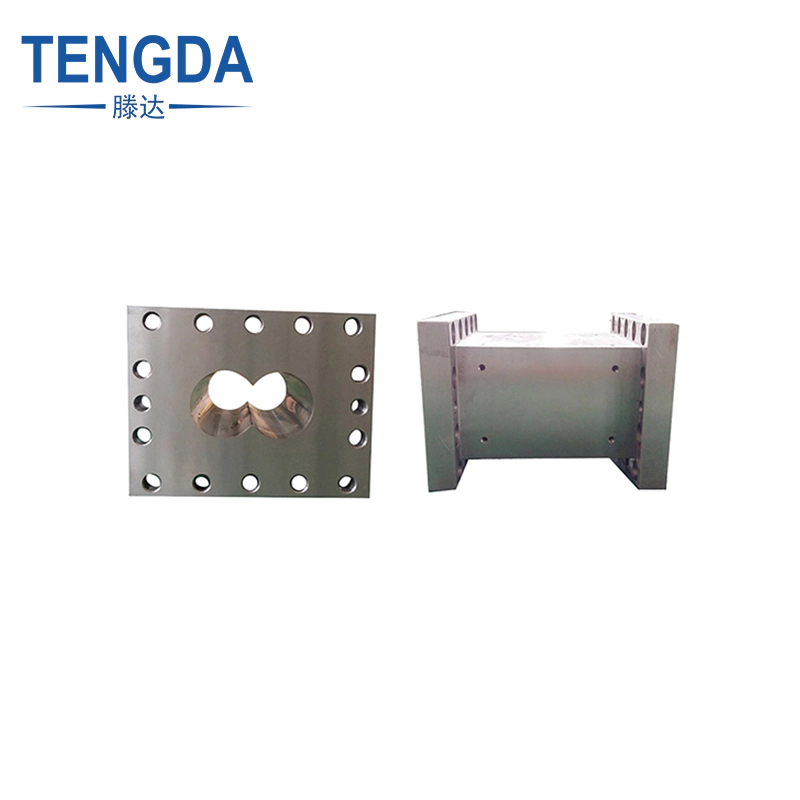

3. Twin-screw plastic granulator barrel

1) Material: 45# steel as the substrate, ∞ inner hole adopts good double alloy bushing;

2) The first cylinder is the feeding cylinder, the sixth cylinder is the natural exhaust cylinder, and the ninth cylinder is the vacuum cylinder

The remaining cylinders are closed cylinders;

3) The cylinder is cooled by soft water;

4) The cylinders are connected by high-strength hexagon socket bolts.

5) Heating section: The feeding area is not heated, and other good cast aluminum heaters are used.

These Application plastic extruder machine manufacturers are meant to serve as a guide for business owners on how to both identify potential opportunities for transformative innovation and how to adapt to the constantly changing technologies of today.

To build customers value by delivering high-quality products, services and solutions in innovative and cost effective ways. Nanjing Tengda Machinery Co., Ltd. will realize this mission by setting the highest standards in service, reliability, safety and cost containment in our industry.

Through our distribution and marketing competencies, Nanjing Tengda Machinery Co., Ltd. provides creative, customized, solutions for our customers. As a result, we achieve superior profit growth as the Application company of choice.

We create a group of experts to promote the quality standard and innovative technology of Application.

To ensure desired results, it is very essential that you get the right kind of from a certified provider..