Breaking Barriers: The Latest in Pellet Equipment Technology

Introducing new advancements in pellet equipment technology that are breaking barriers and revolutionizing the industry. As the demand for renewable energy sources continues to rise, there is an increasing need for efficient and effective pellet equipment. This article explores the latest innovations that are propelling the pellet equipment industry forward. From enhanced pellet production processes to improved pellet quality, these advancements offer promising solutions to meet the growing demand for clean and sustainable energy.

Innovative Designs Enhancing Pellet Production

With the ever-increasing demand for pellets, manufacturers are striving to develop innovative designs that optimize production processes. These advancements are aimed at increasing efficiency, reducing energy consumption, and improving the overall quality of the pellets produced.

A Sophisticated Pelletizing System

One of the breakthroughs in pellet equipment technology is the development of a sophisticated pelletizing system that ensures consistent and uniform pellet formation. This system utilizes advanced control algorithms and real-time monitoring to maintain optimal conditions throughout the pelletizing process. The result is higher productivity and improved pellet quality, as the system can quickly identify any deviations and make necessary adjustments.

The sophisticated pelletizing system also incorporates automated cleaning mechanisms, reducing downtime and increasing overall efficiency. By minimizing the need for manual cleaning and maintenance, manufacturers can focus more on pellet production and meet the growing demand.

Enhanced Drying Technology

Drying is a critical stage in the pellet production process, as it directly affects the final quality of the pellets. Traditional drying methods often result in uneven moisture distribution, leading to inconsistent pellet quality. However, with the latest advancements in drying technology, manufacturers can now achieve uniform moisture levels throughout the pellets.

The enhanced drying technology utilizes precise temperature and humidity controls, ensuring optimal drying conditions for the pellets. Additionally, the system incorporates advanced air circulation mechanisms, promoting even heat distribution and reducing drying time. These improvements result in higher pellet quality and increased productivity, as manufacturers can produce a larger volume of pellets within the same timeframe.

Advanced Die Designs

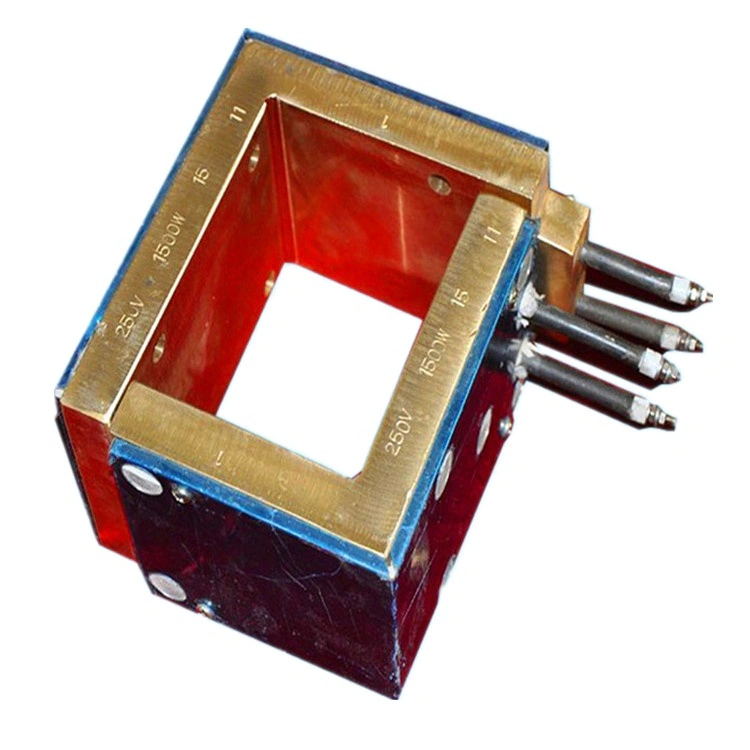

The development of advanced die designs is another significant breakthrough in pellet equipment technology. The die plays a crucial role in shaping the pellets, and any deficiencies in its design can negatively impact the overall quality. The latest advancements in die designs address these concerns, resulting in pellets with improved density and durability.

These advanced die designs incorporate innovative cooling and lubrication systems that prevent die clogging and reduce wear and tear. This not only ensures consistent pellet quality but also extends the lifespan of the die, reducing maintenance and replacement costs for manufacturers. In addition, the improved die designs allow for greater flexibility, enabling manufacturers to produce pellets of varying sizes and shapes to meet specific market demands.

Automated Process Control Systems

Automation is rapidly transforming the pellet equipment industry, and the latest developments in process control systems are making highly efficient and reliable pellet production possible. These automated systems monitor and regulate various parameters throughout the production process, ensuring optimal conditions and consistent pellet quality.

The automated process control systems integrate sensors and advanced analytics to continuously monitor pellet production variables such as temperature, moisture content, and pellet density. This real-time data allows for accurate adjustments and immediate detection of any abnormalities, minimizing wastage and maximizing productivity. Additionally, these systems provide manufacturers with comprehensive data insights, enabling them to identify potential areas for improvement and optimize their processes further.

Implications for the Industry

The latest innovations in pellet equipment technology have significant implications for the industry as a whole. With enhanced pellet production processes, manufacturers can meet the growing demand for renewable energy sources more efficiently and effectively. These advancements not only increase the overall productivity of pellet production but also improve the quality of the pellets, making them more attractive to consumers and end-users.

Furthermore, the development of sophisticated process control systems and automation technologies enables manufacturers to streamline their operations and reduce labor costs. The automation of various production processes enhances efficiency while minimizing human errors, resulting in increased profitability and competitiveness.

In conclusion, the latest advancements in pellet equipment technology are revolutionizing the industry by breaking barriers and pushing the boundaries of what is possible. The sophisticated pelletizing systems, enhanced drying technology, advanced die designs, and automated process control systems collectively contribute to improved pellet production efficiency, higher quality pellets, and increased profitability for manufacturers. As the demand for clean and sustainable energy sources continues to rise, these innovations provide promising solutions to meet the requirements of a rapidly evolving market. The pellet equipment industry is at the forefront of renewable energy technologies, paving the way for a more sustainable future.