Comprehensive 2024 Guide to Thermoplastic Compounding

The field of thermoplastic compounding is an ever-evolving domain that serves as the backbone for various industries, including automotive, construction, electronics, and consumer goods. With the dawn of 2024, new advancements and methodologies have emerged that can greatly benefit those involved in the manufacturing and innovation sectors. Whether you're a seasoned professional or a newcomer, this comprehensive guide aims to elucidate the intricacies of thermoplastic compounding, providing you with insights and knowledge to make informed decisions.

**What is Thermoplastic Compounding?**

Thermoplastic compounding is the process of blending polymers with other materials to improve their mechanical, thermal, and aesthetic properties. During this process, various additives like stabilizers, fillers, and colorants are integrated with the base polymer to create a material with specific characteristics tailored to the requirements of different applications. This meticulous blending ensures the end product can withstand environmental factors, possess enhanced durability, and meet specifications for performance.

The heart of any successful compounding operation lies in the ability to precisely control the mixing process. The base thermoplastic resin is typically fed into an extruder, where it is melted and combined with additives through a series of mixing elements. This process requires precise temperature control, as too high or too low temperatures can lead to the degradation of the polymer or inadequate mixing. The compounded material is then cooled and pelletized for easy handling and further processing.

Understanding the fundamentals of thermoplastic compounding is crucial for anyone involved in the development and manufacturing of plastic products. Whether creating custom materials for a specific application or optimizing existing formulations, the ability to tailor the properties of thermoplastics offers significant advantages in terms of performance and cost-effectiveness.

**Key Components in Thermoplastic Compounding**

Base Resins: The backbone of any compounded material, base resins offer diverse properties ranging from flexibility to rigidity. Common base resins include polyethylene (PE), polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC).

Additives: Various additives including stabilizers, antioxidants, and UV inhibitors are used to enhance the material’s durability and resistance to environmental factors. For instance, stabilizers help in maintaining the polymer's integrity during processing and application, while antioxidants prevent degradation caused by oxidation.

Fillers: Fillers like calcium carbonate, glass fibers, and ceramics are added to improve mechanical strength, thermal stability, and other specific properties. They can also help in reducing material costs by partially replacing the more expensive base resin.

Colorants: These are added to provide aesthetic value and can include pigments or dyes. Colorants must be compatible with the base resin and not adversely affect its mechanical properties.

Processing Aids: Lubricants and dispersants are used to facilitate the manufacturing process, reducing friction and ensuring a uniform distribution of additives within the polymer matrix.

**Advancements in Thermoplastic Compounding Technologies**

As we step into 2024, several exciting advancements in thermoplastic compounding technologies are poised to revolutionize the industry. These innovations promise to enhance the performance, sustainability, and cost-efficiency of compounded materials.

Nanotechnology: The incorporation of nanoparticles into thermoplastic compounds offers significant improvements in mechanical properties, thermal stability, and barrier performance. Nanocomposites, which include materials like carbon nanotubes, nanoclays, and nanosilica, can provide superior strength and toughness with only a small fraction of additive material. This not only improves performance but also helps in maintaining the lightweight nature of thermoplastics.

Biodegradable and Bio-based Polymers: With increasing environmental consciousness, there is a growing demand for sustainable materials. Advances in biodegradable and bio-based polymers continue to progress, offering alternatives to traditional petroleum-based thermoplastics. These materials can be compounded to meet specific performance requirements while ensuring lower environmental impact, making them ideal for applications like packaging, agricultural films, and disposable products.

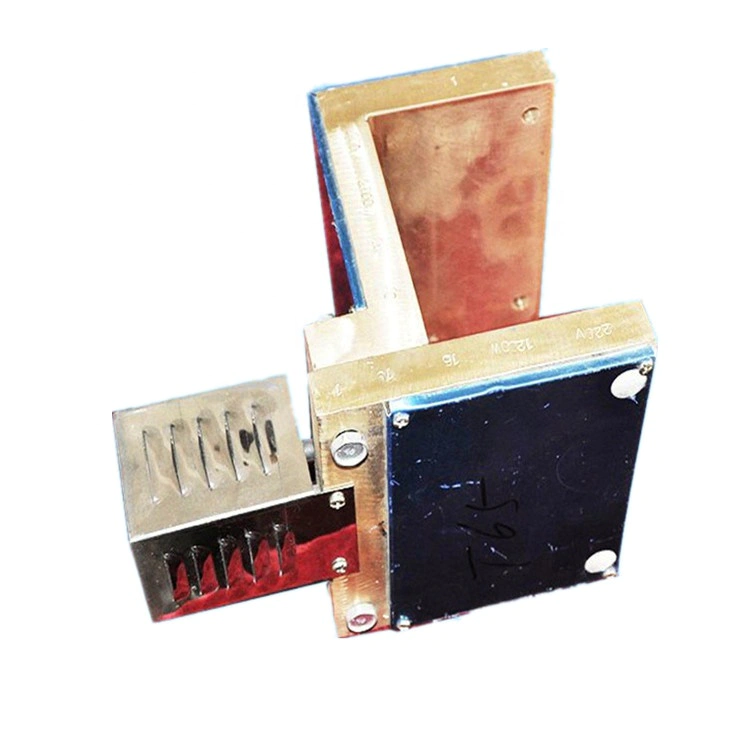

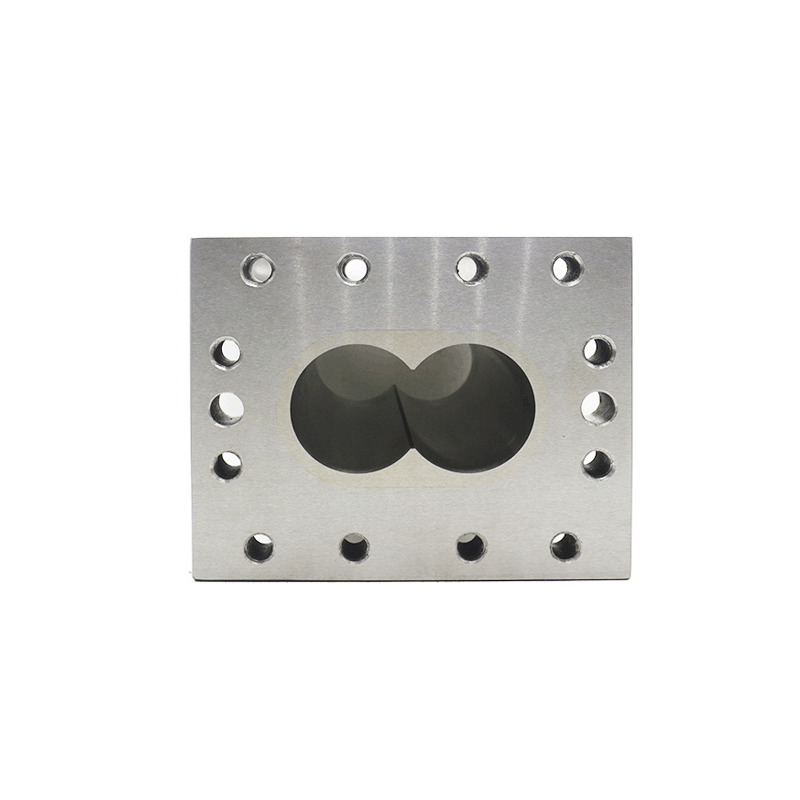

Advanced Compounding Equipment: Cutting-edge compounding equipment, such as twin-screw extruders with more precise control systems, is improving the efficiency and consistency of the compounding process. Innovations like dynamic temperature control, advanced monitoring systems, and optimized screw designs allow for better mixing and dispersion of additives, leading to higher-quality compounded materials.

3D Printing Materials: The evolution of 3D printing has spurred the development of specialized thermoplastic compounds tailored for additive manufacturing. Enhanced formulations offering superior printability, mechanical properties, and surface finish are expanding the applications of 3D printing across various industries.

**Challenges and Solutions in Thermoplastic Compounding**

While the advancements in thermoplastic compounding bring numerous benefits, they also present certain challenges that must be addressed to achieve optimal results. Understanding these challenges and implementing effective solutions is key to successful compounding operations.

Complex Formulations: As the demand for customized materials grows, the complexity of formulations increases. Accurately blending multiple additives and achieving the desired properties can be challenging. Advanced formulation software and rigorous testing protocols can help in predicting and optimizing compound properties, ensuring the final product meets the required specifications.

Compatibility Issues: Incompatibility between base resins and additives can lead to poor dispersion, reduced mechanical performance, and aesthetic defects. Using compatibilizers – specific additives designed to enhance compatibility – can improve the integration of different components within the polymer matrix.

Quality Control: Consistency in compound quality is crucial for ensuring reliable performance. Variations in raw material quality, processing conditions, and equipment performance can affect the final product. Implementing robust quality control measures, including regular testing, in-line monitoring, and process optimization, is essential for maintaining high-quality standards.

Environmental Regulations: Stringent environmental regulations and customer demand for sustainable materials necessitate compliance with specific standards and certifications. Staying updated with the latest regulatory requirements and incorporating eco-friendly practices, such as using recyclable materials and reducing waste, is fundamental for meeting legal and market expectations.

**Applications of Thermoplastic Compounding**

Thermoplastic compounding finds applications across a wide range of industries, showcasing its versatility and significance in modern manufacturing. Each application demands specific properties from the compounded material, highlighting the importance of tailored formulations.

Automotive Industry: Thermoplastic compounds are extensively used in automotive components due to their lightweight, durability, and ease of processing. Applications include interior trims, dashboards, bumpers, and under-the-hood components. Compounded materials offer enhanced impact resistance, thermal stability, and aesthetic flexibility, making them ideal for both structural and decorative parts.

Construction and Building: In the construction industry, thermoplastic compounds are utilized for pipes, profiles, insulation materials, and flooring. Their resistance to chemicals, moisture, and UV radiation, coupled with good mechanical properties, makes them well-suited for demanding construction environments. Customizable formulations enable architects and builders to achieve specific performance criteria.

Electronics and Electrical: Thermoplastic compounds are vital in electronics for producing connectors, housings, and insulating components. Their excellent electrical insulating properties, flame retardancy, and precise molding capabilities are crucial for ensuring the safety and functionality of electronic devices. Innovations in conductive compounds also enable the development of lightweight and efficient components for sophisticated electronic applications.

Consumer Goods: From household appliances to packaging materials, thermoplastic compounds are omnipresent in consumer goods. Their versatility allows for the creation of products that are not only functional but also aesthetically appealing. Applications range from durable kitchenware to flexible packaging solutions, illustrating the compound's adaptability in meeting diverse consumer needs.

Medical Devices: The medical industry relies on thermoplastic compounds for developing medical devices and equipment that require high levels of biocompatibility, sterility, and mechanical performance. Applications include syringes, catheters, diagnostic instruments, and implantable devices. Custom formulations ensure that these medical products meet stringent regulatory standards while providing reliable performance in healthcare settings.

**Future Trends in Thermoplastic Compounding**

The future of thermoplastic compounding is marked by continuous innovation and evolving market demands. Several trends are shaping the direction of the industry, creating opportunities for new applications and improved materials.

Sustainability: The drive towards sustainability is pushing the development of eco-friendly materials and processes. The use of bio-based polymers, recyclables, and biodegradable compounds is on the rise, driven by both regulatory pressures and consumer preferences. Future advancements will likely focus on increasing the availability and performance of sustainable materials.

Smart Materials: The integration of smart technologies into thermoplastic compounds is opening new frontiers. Smart materials that respond to environmental changes, such as temperature, light, and pressure, are being developed for applications in aerospace, healthcare, and consumer electronics. These materials can enhance product functionality and create innovative user experiences.

Digitalization and Industry 4.0: The advent of Industry 4.0 is revolutionizing manufacturing, including thermoplastic compounding. Digitalization, automation, and data analytics are being implemented to optimize production processes, improve quality control, and reduce downtime. The integration of IoT devices and AI-driven analytics allows for predictive maintenance and real-time process adjustments, enhancing overall efficiency.

In conclusion, thermoplastic compounding is a dynamic and multifaceted field, continually adapting to technological advancements and market needs. By understanding the fundamentals, leveraging new technologies, addressing challenges, and exploring diverse applications, manufacturers can develop high-performance materials that meet the demands of modern industries. The future trends in sustainability, smart materials, and digitalization promise to further elevate the capabilities and scope of thermoplastic compounds, solidifying their indispensable role in various sectors.

However, Application isn't the only producer in domestic, and many people feel that Nanjing Tengda Machinery Co., Ltd.'s service leaves much to be desired in terms of functionality and design.

Nanjing Tengda Machinery Co., Ltd. endeavors to be valued as an industry leader in client satisfaction, sales growth, product performance, financial strength and profitability.

Nanjing Tengda Machinery Co., Ltd. prepares for every aspect of running a business, and this includes developing a sound understanding and ability to manage the financial aspects of our company, including financial analysis, taxes and budgeting.