Crafting Sustainability: Choosing the Right Plastic Recycling Pelletizer Machine

Introduction:

Plastic recycling has become an essential practice in today's world, where sustainability and environmental responsibility are paramount. As the demand for recycled plastic continues to grow, choosing the right plastic recycling pelletizer machine is of utmost importance. The pelletizer machine plays a vital role in the plastic recycling process, transforming plastic waste into useful plastic pellets that can be used for various applications. This article will delve into the significance of choosing the right plastic recycling pelletizer machine, exploring its benefits, key considerations, and the various types available in the market.

Understanding the Plastic Recycling Process:

Before delving into the specifics of a plastic recycling pelletizer machine, it is crucial to understand the plastic recycling process as a whole. Plastic recycling involves multiple stages, starting from sorting and collecting plastic waste to transforming it into reusable plastic pellets. The process begins with collecting and sorting plastic waste based on its type and quality. Once sorted, the plastic waste goes through a series of steps, including cleaning, grinding, and melting, to form plastic flakes. These flakes are then fed into a plastic recycling pelletizer machine, where they are transformed into plastic pellets.

The Benefits of Plastic Recycling:

Plastic recycling offers numerous benefits, both from an environmental and economic standpoint. By diverting plastic waste from landfills, it minimizes the pollution caused by plastic materials and reduces the extraction of virgin resources. Recycling plastic also helps conserve energy as producing plastic from recycled materials requires less energy compared to producing plastic from scratch. Moreover, recycling plastic contributes to the circular economy by promoting the reuse of materials and reducing the need for new plastic production. Furthermore, the economic benefits of plastic recycling cannot be understated, as it generates job opportunities and contributes to the growth of the recycling industry.

The Role of a Plastic Recycling Pelletizer Machine:

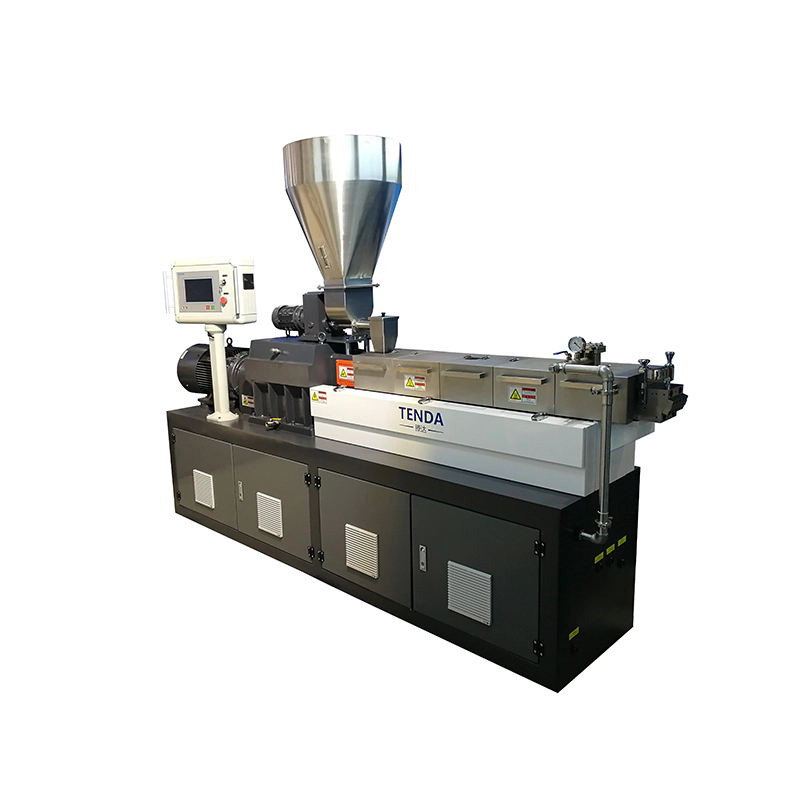

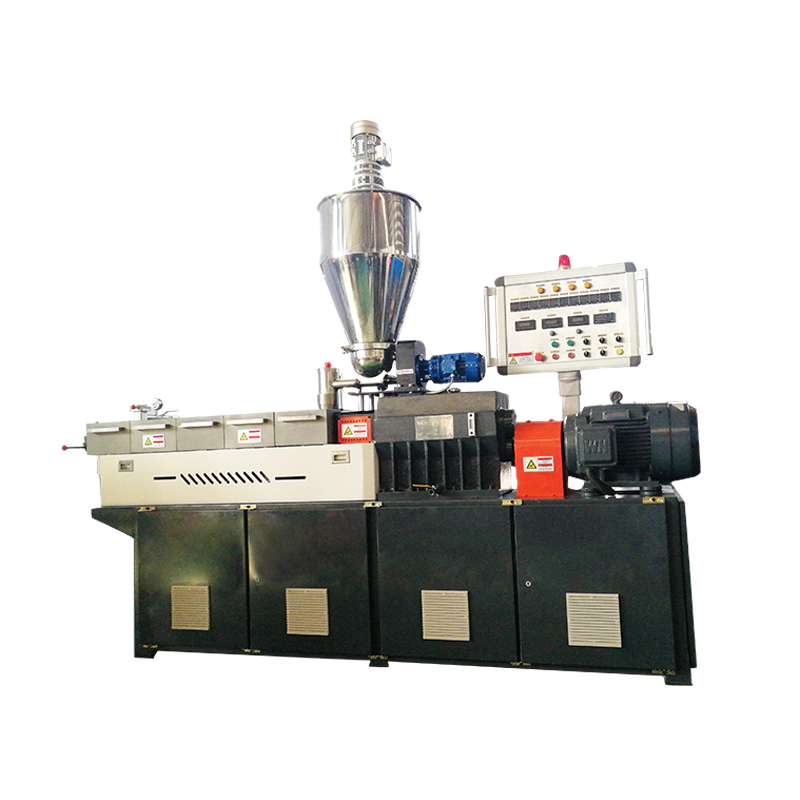

A plastic recycling pelletizer machine is a crucial component of the plastic recycling process. Its primary function is to transform plastic flakes into plastic pellets, which are uniform in shape and size. These plastic pellets serve as the foundation for various downstream applications, including the manufacturing of new plastic products. The pelletizer machine employs a combination of heat, pressure, and mechanical force to melt the plastic flakes and then extrude them through a die, resulting in the formation of consistent plastic pellets.

The Key Considerations for Choosing the Right Pelletizer Machine:

When selecting a plastic recycling pelletizer machine, several key considerations need to be taken into account to ensure optimal performance and productivity. These considerations include:

1. Types of Plastic:

Different types of plastic require specific pelletizing techniques and machines. For instance, polyethylene terephthalate (PET) has different characteristics compared to polyvinyl chloride (PVC). Therefore, it is crucial to choose a pelletizer machine that can effectively process the specific type of plastic you intend to recycle.2. Capacity:

The capacity of the pelletizer machine determines the quantity of plastic waste it can process within a given time frame. It is essential to assess your recycling needs and select a machine that aligns with your production requirements. Consider factors such as the amount of plastic waste generated, the desired pellet output, and future scalability.3. Pellet Quality:

The quality of the plastic pellets produced by the machine is vital, as it affects their usability in downstream applications. Factors such as pellet uniformity, size consistency, and absence of contaminants are crucial in ensuring high-quality pellets. Look for a machine that offers precise control over temperature, pressure, and extrusion speed to achieve the desired pellet quality.4. Automation and Control:

Automation and control features play a significant role in optimizing the efficiency and productivity of the pelletizer machine. Advanced machines offer features such as automatic start-stop functions, temperature controls, and real-time monitoring systems. These features not only enhance operational efficiency but also reduce the risk of human error.5. Maintenance and Support:

Like any machinery, a plastic recycling pelletizer machine requires regular maintenance and occasional repairs. It is essential to choose a machine from a reputable manufacturer that offers reliable customer support, readily available spare parts, and maintenance services. This ensures maximum uptime and minimizes downtime due to machine breakdowns.The Different Types of Plastic Recycling Pelletizer Machines:

1. Strand Pelletizing:

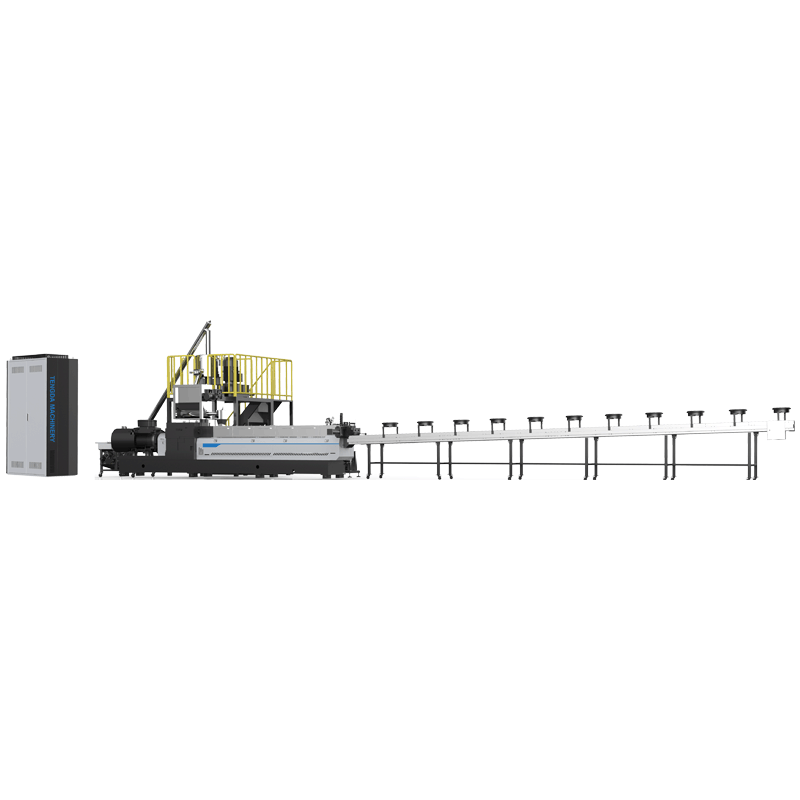

Strand pelletizing is one of the most common pelletizing methods used in plastic recycling. In this process, the molten plastic is extruded through a die and then cooled in a water bath to form strands. These strands are then fed into a pelletizer, where they are cut into uniform pellets. Strand pelletizing machines are highly versatile and can process a wide range of plastics.2. Underwater Pelletizing:

Underwater pelletizing is a more advanced and efficient pelletizing method, particularly suitable for high-demand applications. In underwater pelletizing, the molten plastic is extruded through a die and immediately cut into pellets by a rotary cutter submerged in water. The water cools the plastic rapidly, resulting in high-quality pellets with minimal heat-induced degradation.3. Hot Die Face Pelletizing:

Hot die face pelletizing is primarily used for thermoplastic materials that are sensitive to heat. In this method, the molten plastic is extruded through a die and then cut into pellets by a heated blade. The hot blade effectively seals the cut surface, preventing the pellets from sticking together or deforming.4. Air Cooling Strand Pelletizing:

Air cooling strand pelletizing is a variation of the strand pelletizing method. Instead of using a water bath to cool the strands, air is blown onto the strands to solidify the plastic. This method is particularly suitable for processing heat-resistant plastics or when water-based cooling is not desired.5. Centrifugal Pelletizing:

Centrifugal pelletizing is a specialized method used for highly viscous or sticky plastic materials. In this process, the molten plastic is fed into a spinning rotor, which flings the plastic against the inner surface of a cylindrical chamber. The rapid centrifugal force causes the plastic to solidify and break into pellets.Conclusion:

Choosing the right plastic recycling pelletizer machine is crucial for achieving efficient and sustainable plastic recycling. By understanding the plastic recycling process, considering key factors, and exploring different types of pelletizing machines, one can make an informed decision to invest in the most suitable machine. The right pelletizer machine can significantly impact the quality of plastic pellets produced, the overall productivity, and the economic viability of your recycling operation. Embracing sustainable practices and investing in the right machinery are essential steps towards a greener and more environmentally responsible future.

However, Application isn't the only producer in domestic, and many people feel that Nanjing Tengda Machinery Co., Ltd.'s service leaves much to be desired in terms of functionality and design.

Check out TENGDA Extruder Machine Manufacturers for optimal quality products, and get your Application problem fixed. Send us an enquiry or make a call if you are interested.

Nanjing Tengda Machinery Co., Ltd. provides a way for you to understand your customers, to learn what makes them unique and what motivates their behavior. We can then leverage that wealth of information to personalize our interactions and demonstrate that Application is valuable to our customers.

While the productivity and efficiency benefits of automation are unequivocal for manufacturing Application, the need for skilled humans to operate, utilize and advance technologies is equally unmistakable.