Custom Plastic Extrusion Companies: Finding the Best Provider for Your Needs

Introduction:

Plastic extrusion is a widely used manufacturing process that involves shaping raw plastic materials into desired forms. It is a versatile method used in various industries for the production of custom plastic products. However, finding the right custom plastic extrusion company can be a daunting task, considering the multitude of providers available in the market. This article aims to guide you through the process of finding the best provider for your specific needs, ensuring high-quality products and an efficient collaboration.

Understanding Plastic Extrusion and Its Applications

Plastic extrusion is a manufacturing process that involves heating raw plastic material and forcing it through a die to create continuous lengths of various shapes and sizes. This method is widely utilized due to its efficiency, cost-effectiveness, and ability to produce complex profiles.

Plastic extrusion finds its applications in numerous industries. One of the most common industries benefiting from plastic extrusion is the construction industry, where PVC and other plastic materials are extruded into pipes, tubing, and profiles used in plumbing, electrical systems, and building components. Automotive companies also rely on plastic extrusion for manufacturing parts such as weatherstripping, window seals, and decorative trims. Additionally, the packaging industry utilizes extruded plastics for creating containers, bottles, and films.

Choosing the right plastic extrusion company is crucial to ensure the production of high-quality customized products that meet your specific requirements.

Factors to Consider When Choosing a Custom Plastic Extrusion Provider

When selecting a custom plastic extrusion provider, there are several key factors that should be considered to ensure an optimal partnership. These factors include:

1. Experience and Expertise:

Opting for an experienced company with a proven track record is essential. Look for a provider that has several years of experience in plastic extrusion and a deep understanding of different materials and their unique properties. An experienced provider will be able to offer valuable insights, technical expertise, and innovative solutions to meet your specific needs.

2. Customization Capabilities:

Every industry and project demand unique specifications. Ensure that the custom plastic extrusion provider you choose has the necessary capabilities to fulfill your customization requirements. The company should have a comprehensive understanding of various materials, equipment, and extrusion processes to deliver tailored solutions.

3. Quality Control:

Maintaining strict quality control measures is crucial in plastic extrusion. A reputable provider should have stringent quality control processes in place, ensuring that the delivered products meet the required specifications and industry standards. This involves meticulous testing, inspection, and adherence to quality management systems.

4. Material Options:

Different projects may require specific plastic materials to meet desired properties like strength, flexibility, or temperature resistance. A reliable custom plastic extrusion provider should offer a wide range of material options to choose from, such as PVC, HDPE, ABS, or polycarbonate. The ability to provide different material options ensures the compatibility of the final product with its intended application.

5. Collaborative Approach:

Effective communication and collaboration between you and the custom plastic extrusion provider are vital for a successful project outcome. Look for a company that values transparency, listens attentively to your requirements, and is willing to work closely with you throughout the entire process. A collaborative approach ensures that all your needs are met and potential issues are addressed promptly.

Conclusion

Choosing the right custom plastic extrusion provider is crucial to obtain high-quality customized products that meet your specific requirements. Consider factors such as experience, customization capabilities, quality control measures, material options, and a collaborative approach when making your decision. By evaluating potential providers against these criteria, you can ensure a successful partnership that delivers efficient, cost-effective, and tailored plastic extrusion solutions. Remember, finding the best provider may require some research and consideration, but the benefits of partnering with a reputable company will undoubtedly outweigh the efforts spent in the selection process.

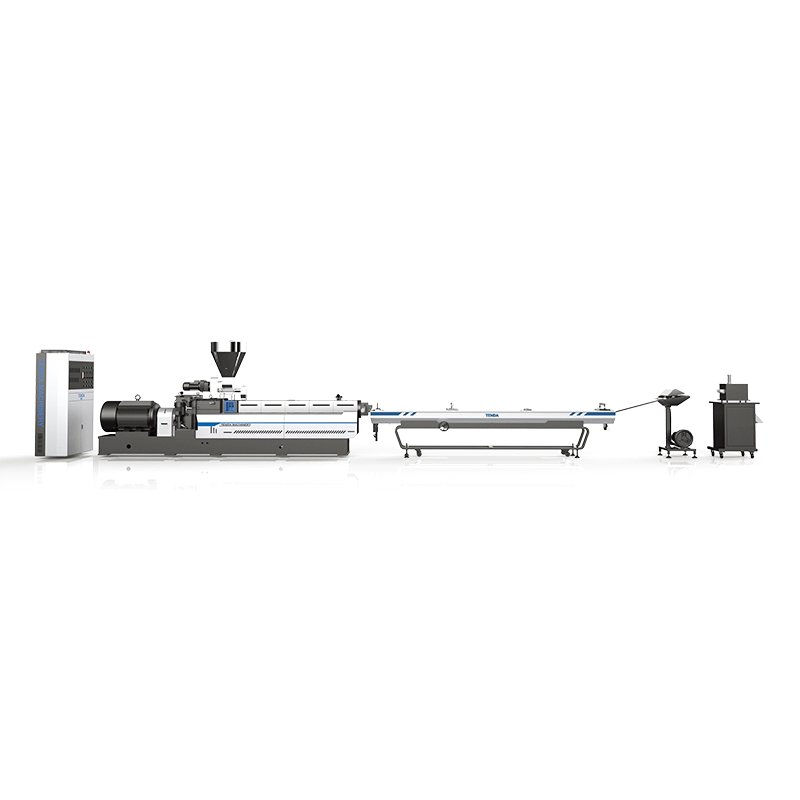

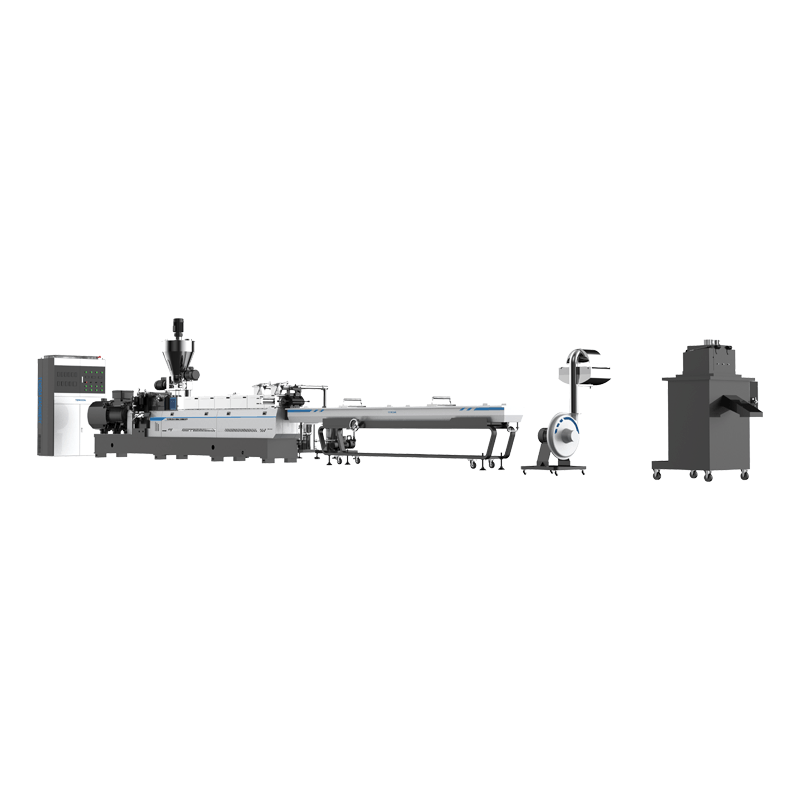

Anyone who has seen the latest plastic extruder machine manufacturers Application in operation cannot help but be impressed with how far the technology has progressed over the past few years.

should only be created by the very best Application companies with the training, experience and know how about what is expected of them.

For optimal extruder machine manufacturers, choose a high-quality Application system and make sure a certified installer sets it up.