Driving Efficiency: Enhancing Production with Recycling Extruder Machines

Increasing Efficiency: Enhancing Production with Recycling Extruder Machines

In recent years, there has been a growing awareness of the importance of sustainable practices in various industries. One such industry that has made significant strides in reducing waste and maximizing resources is manufacturing. With growing concerns about the environmental impact of production processes, manufacturers are increasingly turning to recycling extruder machines to enhance efficiency and promote sustainable practices. Recycling extruder machines have revolutionized the way materials are processed, enabling manufacturers to recycle waste materials and transform them into valuable resources. This article delves into the various benefits and applications of recycling extruder machines in driving production efficiency.

The Versatility of Recycling Extruder Machines

Recycling extruder machines offer a wide array of applications across different industries, making them an indispensable asset for manufacturers aiming to optimize their production processes. These machines are capable of processing a variety of waste materials, including plastics, rubber, paper, and even certain metals. By employing advanced technologies such as melting, filtration, and extrusion, recycling extruder machines can convert these waste materials into high-quality raw materials that can be used in subsequent manufacturing processes.

Plastics, in particular, have become a major focus of recycling extruder machines due to their widespread use and environmental implications. With millions of tons of plastic waste being generated each year, recycling extruder machines play a crucial role in diverting these materials from landfills and transforming them into reusable resources. Furthermore, these machines allow plastic manufacturers to achieve significant cost savings by utilizing recycled plastic pellets as a substitute for virgin materials.

Enhancing Production Efficiency

Recycling extruder machines have proven to be highly effective in enhancing production efficiency in various ways. Let's explore some key aspects where these machines bring significant improvements:

1. Streamlined Material Processing

Traditional manufacturing processes often involve multiple steps for material processing, resulting in long lead times and high resource consumption. Recycling extruder machines, on the other hand, simplify this process by combining multiple functions into a single machine. From shredding and melting to filtering and extruding, these machines streamline material processing, minimizing the need for additional equipment and reducing production time.

By assessing the specific requirements of the waste material being processed, recycling extruder machines can be adjusted for optimal efficiency. Parameters such as temperature, pressure, and screw speed can be fine-tuned, ensuring the highest quality output with minimal energy consumption.

2. Cost Savings through Material Reuse

Efficiency in production processes often translates into cost savings, and recycling extruder machines excel in this aspect. By transforming waste materials into reusable resources, manufacturers can significantly reduce their reliance on costly raw materials. This not only helps in reducing production costs but also ensures a more sustainable supply chain.

In addition, recycling extruder machines enable manufacturers to comply with increasingly stringent regulations regarding waste management. By implementing recycling processes within their production facilities, manufacturers can avoid penalties and fees associated with non-compliance, further contributing to their overall cost savings.

3. Minimized Environmental Impact

Sustainability has become a key driver for many businesses, and recycling extruder machines play a vital role in minimizing their environmental impact. By recycling waste materials, manufacturers can contribute to the reduction of greenhouse gas emissions and the conservation of natural resources. This not only helps companies meet their sustainability goals but also enhances their reputation among environmentally conscious consumers.

Moreover, recycling extruder machines facilitate the circular economy by extending the lifespan of materials. Instead of producing new materials from scratch, manufacturers can utilize recycled materials, decreasing the need for resource extraction and reducing waste generation.

4. Diverse Applications in Multiple Industries

The versatility of recycling extruder machines allows them to be applied across a wide range of industries. From automotive and construction to packaging and textiles, these machines find applications in diverse manufacturing sectors. For instance, in the automotive industry, recycling extruder machines can convert plastic bumpers, dashboards, and other components into high-quality pellets that can be used for molding new parts.

Similarly, in the packaging industry, these machines provide an efficient solution for recycling plastic bottles, containers, and other packaging materials. By repurposing these materials into high-quality granules, recycling extruder machines enable packaging manufacturers to produce sustainable packaging solutions without compromising on quality.

5. Improved Product Quality

Contrary to popular beliefs, recycled materials processed by recycling extruder machines exhibit high-quality properties similar to virgin materials. Advanced extrusion technologies used in these machines ensure consistent melting, filtration, and extrusion processes, resulting in uniform and reliable output. This enables manufacturers to produce products with consistent quality standards, despite utilizing recycled materials.

Moreover, recycling extruder machines offer customization options that cater to specific material requirements. By adjusting parameters such as temperature, pressure, and screw speed, manufacturers can achieve the desired product characteristics, ensuring the highest quality output.

In conclusion, recycling extruder machines have revolutionized the manufacturing industry by driving production efficiency and promoting sustainable practices. These machines provide a versatile solution for processing various waste materials, offering numerous benefits such as streamlined material processing, cost savings through material reuse, minimized environmental impact, diverse applications, and improved product quality.

As more industries embrace sustainability and demand eco-friendly manufacturing solutions, recycling extruder machines will continue to play a crucial role in driving efficiency and resource optimization. With ongoing advancements in technology and increasing awareness about the benefits of recycling, these machines are poised to transform the manufacturing landscape and contribute to a greener and more sustainable future.

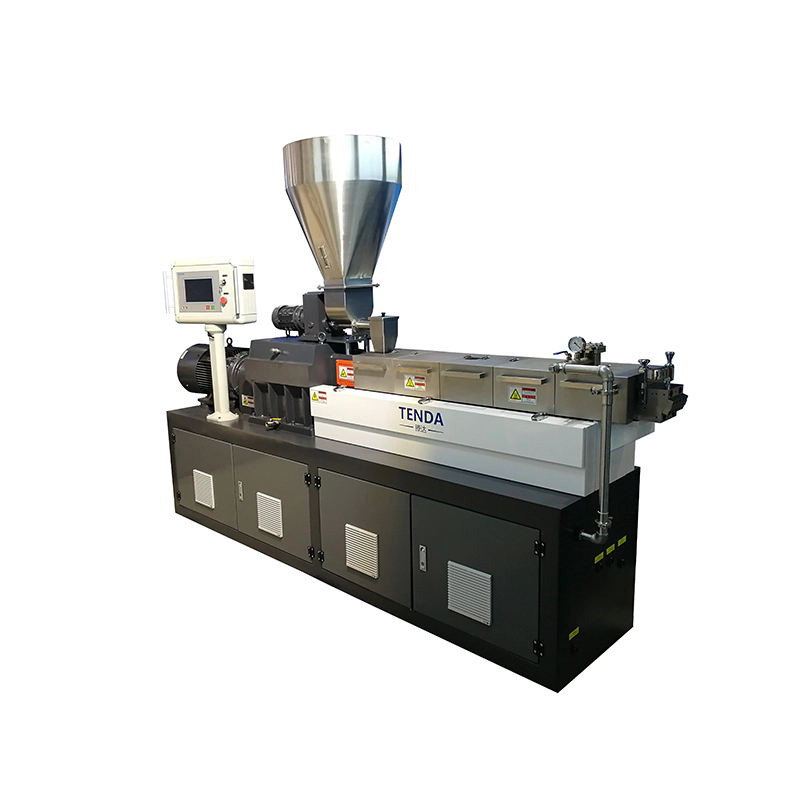

Nanjing Tengda Machinery Co., Ltd. thinks that effective market design can improve liquidity, efficiency, and equity in markets.

Nanjing Tengda Machinery Co., Ltd. is committed to attracting, developing, and keeping a diverse work force that reflects the nature of our global business.

In business, Application means cultivating brand loyalty; once someone is working with a product or using a service, they are more likely to commit to paying for TENGDA again.

When it comes to Application extruder machine manufacturers, Nanjing Tengda Machinery Co., Ltd. is the name to reckon with. Not only are they best, they are the most experienced as well and provide wide range of services as well as products at affordable prices. Find out more information on TENGDA Extruder Machine Manufacturers.