Driving Efficiency: Exploring Cutting-Edge Pelletizing Machines

Introduction

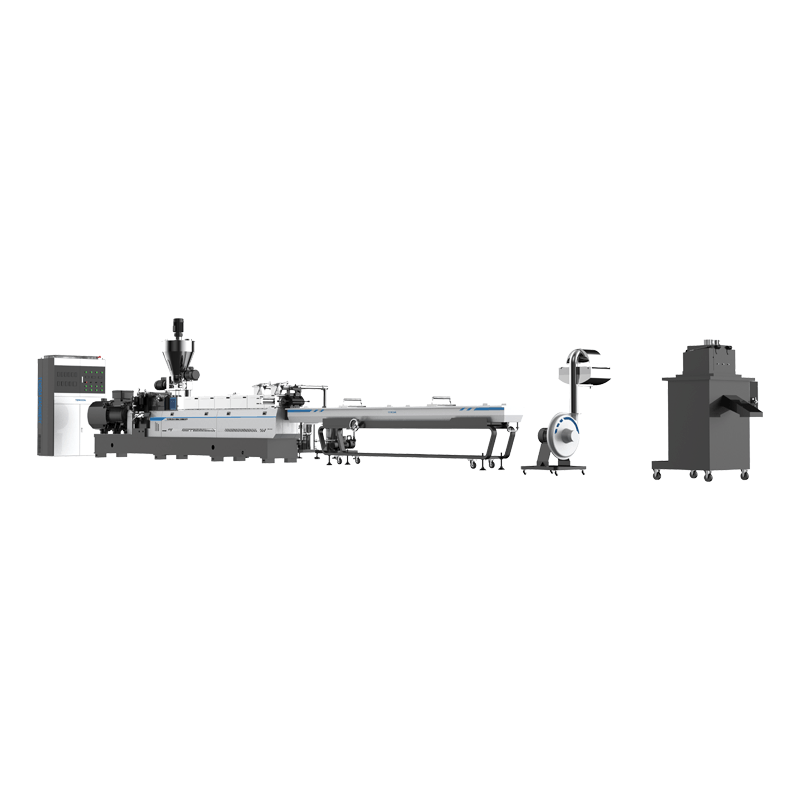

Pelletizing machines are crucial in the manufacturing industry as they play a significant role in converting various materials into pellets. These versatile machines have revolutionized the process by offering increased efficiency and improved productivity. With cutting-edge technology advancements, pelletizing machines have become more reliable, precise, and energy-efficient. In this article, we will explore the latest innovations in pelletizing machines that are driving efficiency in the industry.

The Importance of Pelletizing Machines

Pelletizing machines have gained immense popularity in a wide range of industries, from plastics and chemicals to pharmaceuticals and agriculture. These machines are responsible for transforming raw materials, often in powder or granular form, into small, cylindrical pellets. The pellets offer numerous advantages, including enhanced handling, reduced dust formation, improved flow properties, and better product uniformity.

Pelletizing machines are commonly used in the plastic industry to convert raw plastic materials into uniform pellets. These pellets can then be used in the production of various plastic products, such as bottles, containers, and films. The automation and efficiency of modern pelletizing machines have significantly increased production rates, reduced waste, and improved the quality of plastic products.

Similarly, in the chemical industry, pelletizing machines play a vital role in manufacturing fertilizers, catalysts, pigments, and other chemical products. By converting the raw materials into pellets, these machines enable easy handling, transportation, and storage. The precise control over pellet size and shape ensures consistent quality and desired chemical properties in the final products.

The Advancements in Pelletizing Technology

In recent years, there have been remarkable advancements in pelletizing machine technology, driven by the need for higher efficiency, product quality, and sustainability. Let's explore some of the cutting-edge innovations that are transforming the pelletizing process.

1. Customization and Flexibility

Modern pelletizing machines offer a high degree of customization and flexibility to meet the diverse needs of different industries. Manufacturers can now tailor the machines to specific requirements in terms of pellet size, shape, density, and composition. This flexibility allows various materials, including polymers, metals, ceramics, and food products, to be effectively pelletized, opening up new possibilities in product development and manufacturing.

By incorporating advanced control systems, pelletizing machines can adjust process parameters in real-time, ensuring consistent pellet quality and optimizing production efficiency. These systems provide precise control over variables such as temperature, screw speed, die design, and cooling rate, enabling manufacturers to achieve the desired pellet characteristics with minimal waste and energy consumption.

2. Increased Throughput and Productivity

One of the primary goals of modern pelletizing machines is to maximize throughput and productivity. Manufacturers are constantly striving to improve machine designs and optimize process parameters to achieve higher production rates. Advanced screw designs and extrusion systems allow for higher feed rates and improved material compaction, resulting in increased throughput without compromising on pellet quality.

Additionally, the integration of automation, robotics, and data analytics has revolutionized the pelletizing process. Automatic feeding systems, inline quality monitoring, and real-time data analysis enable continuous operation, reduced downtime, and proactive maintenance. These advancements have significantly improved overall productivity, reducing production costs, and enhancing competitiveness in the market.

3. Energy Efficiency and Sustainability

In the era of environmental consciousness, energy efficiency and sustainability have become critical factors in the design and operation of pelletizing machines. Manufacturers are actively incorporating innovative technologies to minimize energy consumption and reduce the carbon footprint of the pelletizing process.

Modern pelletizing machines utilize energy-efficient motors, optimized heat transfer systems, and intelligent control algorithms to minimize energy loss during operation. Variable frequency drives (VFDs), for instance, allow the adjustment of motor speed based on the required output, reducing energy consumption during low-demand periods. Heat recovery systems capture and reuse waste heat, further enhancing energy efficiency.

Furthermore, sustainability is being addressed through the incorporation of biodegradable materials, recycling systems, and waste reduction strategies. Pelletizing machines are being designed to facilitate the use of biopolymers and recycled materials, promoting a circular economy and reducing reliance on virgin resources. These initiatives have a positive impact on the environment, making pelletizing machines more sustainable and eco-friendly.

4. Process Automation and Integration

Automation and integration of pelletizing machines with other manufacturing processes have become essential for efficient operations. Pelletizing machines can now be integrated into a complete production line, incorporating material handling, drying, blending, and packaging systems.

Automation not only simplifies the operation but also improves the overall process control, reducing human error and variability. Sophisticated control systems enable seamless coordination between different units, ensuring smooth material flow and minimizing downtime.

Additionally, advancements in robotics and artificial intelligence (AI) have introduced new possibilities in pelletizing machines. Robots can be programmed to perform tasks such as mold changeovers, die cleaning, and quality inspection, providing higher precision, speed, and repeatability. AI algorithms can analyze data in real-time, identifying patterns and optimizing process parameters for enhanced efficiency.

5. Enhanced Product Quality

Improving product quality is a constant pursuit in the manufacturing industry, and pelletizing machines play a vital role in achieving this objective. The latest innovations in pelletizing technology have significantly enhanced the quality and consistency of the produced pellets.

Advanced die designs, combined with precise control over process parameters, allow manufacturers to achieve uniform pellet size and shape distribution. The elimination of irregularities ensures better flow properties, reduced segregation, and improved downstream processing.

Furthermore, advanced cooling systems enable rapid cooling of the pellets, locking in the desired properties and preventing degradation. This results in pellets with optimized mechanical strength, reduced brittleness, and improved performance in the final application.

Conclusion

The continuous advancements in pelletizing machine technology are driving efficiency in various industries, revolutionizing the manufacturing processes. The customization and flexibility offered by modern machines allow manufacturers to produce pellets with precise characteristics for different applications. Increased throughput, energy efficiency, and sustainability have become key focuses, leading to higher productivity and reduced environmental impact.

Process automation, integration, and enhanced product quality are other significant benefits of the latest pelletizing machines. These machines are shaping the future of manufacturing by improving operational efficiency, reducing costs, and enabling the development of innovative products.

As technology continues to evolve, it is expected that pelletizing machines will become even more advanced, delivering higher efficiency, improved performance, and greater sustainability. The industry can look forward to continued innovation and the adoption of cutting-edge technologies in the pursuit of driving efficiency through pelletizing.

Nanjing Tengda Machinery Co., Ltd. has an array of branches in domestic for servicing customers with high-quality products.

We would appreciate your immediate attention to Application.

Nanjing Tengda Machinery Co., Ltd. employs a numbers of citizens, helping them and their families achieve a higher standard of living.

Nanjing Tengda Machinery Co., Ltd. quickly recognized the power of efficient manufacturing and started proactively recruiting people to sell products.