Driving Efficiency: The Power of Extruder Pelletizer Systems

Introduction

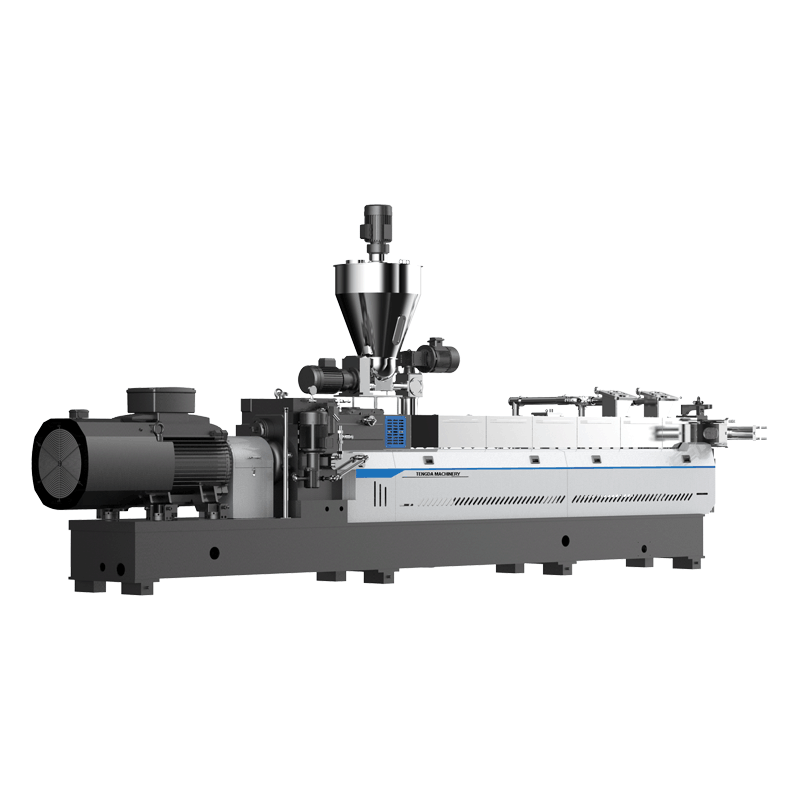

Extruder pelletizer systems are revolutionizing the manufacturing industry by driving efficiency to new heights. These systems have emerged as invaluable tools, allowing businesses to optimize their operations and enhance the quality of their products. By combining the power of extrusion and pelletization, these systems offer a range of benefits to various industries, including plastics, food processing, pharmaceuticals, and chemicals.

With their ability to convert raw materials into uniform pellets, extruder pelletizer systems have become the go-to solution for companies seeking to streamline their production processes. In this article, we will delve into the world of extruder pelletizers, exploring their mechanisms, functionality, and the advantages they offer. Let us embark on a journey to discover the power of extruder pelletizer systems.

Understanding Extruder Pelletizers

Extruder pelletizers are mechanical devices designed to transform various materials, typically in powder or granular form, into uniform pellets through a combination of extrusion and pelletization processes. These systems utilize heated instruments, such as screws, to melt the materials and then force them through a die to create cylindrical pellets of uniform shape and size.

The extrusion process begins with the introduction of raw materials into the extruder. Typically, the materials are fed into a hopper, where they are transported into the barrel of the extruder using an Archimedean screw. Inside the barrel, the materials are exposed to heat and pressure, causing them to melt and become cohesive.

As the molten material progresses along the barrel, it encounters a die plate that determines the shape and size of the pellets. The material is then extruded through the holes of the die plate, resulting in the formation of cylindrical pellets. These pellets are subsequently cooled, solidified, and cut to the desired length by a pelletizer, completing the pelletization process.

The Advantages of Extruder Pelletizer Systems

The utilization of extruder pelletizer systems brings numerous advantages to manufacturers across various industries. Let us explore some of the key benefits that these systems offer:

1. Enhanced Efficiency and Productivity

Extruder pelletizer systems enable companies to achieve significantly higher levels of efficiency and productivity in their manufacturing processes. By automating the production of uniform pellets, these systems eliminate the need for manual labor, reducing the risk of human errors and ensuring consistent quality. Moreover, the continuous operation of extruder pelletizer systems allows for uninterrupted production, resulting in higher output rates and improved production turnaround times.

2. Improved Pellet Quality

The utilization of extruder pelletizer systems enables manufacturers to produce pellets of superior quality. The controlled heating and pressure conditions within the extruder ensure optimal material melting, resulting in consistent and uniform pellets. The die plate further contributes to the uniformity of the pellets, ensuring precise dimensions and eliminating irregularities. With enhanced pellet quality, manufacturers can deliver products that meet stringent industry standards, enhancing their reputation and customer satisfaction.

3. Versatile Range of Materials

One of the significant advantages of extruder pelletizer systems is their ability to process a wide range of materials. From plastics and composites to food ingredients and chemicals, these systems can handle diverse materials, allowing businesses to explore various product possibilities. This versatility not only enables manufacturers to expand their product offerings but also paves the way for innovation and the development of new materials and formulations.

4. Cost Savings

The implementation of extruder pelletizer systems can lead to substantial cost savings for manufacturers. By automating the process and eliminating the need for manual labor, these systems minimize labor costs and reduce the risk of errors, such as inconsistent pellet sizes. Additionally, the continuous operation of extruder pelletizer systems optimizes energy consumption and reduces production downtime, further contributing to cost savings.

5. Environmental Benefits

Extruder pelletizer systems offer several environmental benefits, making them a sustainable choice for manufacturers. The precise control of material melting and the elimination of irregularities result in minimal material wastage. Moreover, the efficient cooling and solidification processes of the pellets lead to energy savings. By adopting extruder pelletizer systems, companies can reduce their environmental footprint and contribute to a greener future.

Applications of Extruder Pelletizer Systems

Extruder pelletizer systems find applications in a wide range of industries, thanks to their versatility and efficiency. Let us explore some of the key applications of these systems:

1. Plastics Industry

Extruder pelletizer systems play a vital role in the plastics industry, enabling the production of high-quality plastic pellets. These pellets serve as the foundation for various plastic products, such as films, sheets, pipes, and profiles. The ability of extruder pelletizer systems to process a wide range of plastics, including polyethylene, polystyrene, and polypropylene, makes them a crucial component in the plastic manufacturing process.

2. Food Processing

In the food processing industry, extruder pelletizers are utilized for the production of food ingredients, such as cereal flakes, pasta, and snacks. The ability of these systems to handle diverse food materials, including grains, dough, and powders, makes them an essential tool for food processors. Extruder pelletizers ensure consistent quality and precise control over the shape and size of food pellets, meeting the stringent standards of the food industry.

3. Pharmaceuticals

Extruder pelletizer systems are extensively used in the pharmaceutical industry for the production of pharmaceutical pellets and granules. These pellets serve as a controlled-release delivery system for medications, ensuring precise dosages and improved patient compliance. The ability of extruder pelletizer systems to handle heat-sensitive materials and control the density and dissolution properties of the pellets makes them indispensable in pharmaceutical manufacturing.

4. Chemicals and Fertilizers

In the chemicals and fertilizers industry, extruder pelletizer systems enable the conversion of chemicals and fertilizers into easily transportable and manageable pellets. These pellets offer improved handling, storage, and dispersion properties compared to bulk materials. The ability to optimize the size, shape, and porosity of the pellets allows manufacturers to enhance the performance and efficacy of chemical products and fertilizers.

5. Recycling Industry

Extruder pelletizer systems also find applications in the recycling industry, enabling the conversion of recycled materials, such as plastic waste, into reusable pellets. These pellets serve as valuable raw materials for various industries, promoting sustainability and circular economy practices. The ability to process different types of recyclable materials makes extruder pelletizer systems an integral part of recycling initiatives.

The Future of Extruder Pelletizer Systems

Extruder pelletizer systems have emerged as indispensable tools for various industries, offering a range of benefits, from enhanced efficiency and productivity to improved product quality and cost savings. As manufacturing processes continue to evolve, the demand for these systems is expected to rise further.

In the future, advancements in technology and materials science are likely to drive innovation in extruder pelletizer systems. Manufacturers can anticipate the development of systems capable of handling even more diverse materials and achieving higher precision and automation levels. Furthermore, there will be a greater emphasis on sustainability, with the incorporation of eco-friendly features and energy-efficient solutions in extruder pelletizer systems.

Conclusion

Extruder pelletizer systems have revolutionized the manufacturing industry, providing businesses with the means to optimize their production processes and enhance the quality of their products. With their ability to convert raw materials into uniform pellets, these systems offer advantages such as enhanced efficiency and productivity, improved product quality, versatility in material processing, cost savings, and environmental benefits.

The applications of extruder pelletizer systems span across industries, including plastics, food processing, pharmaceuticals, chemicals, and recycling. These systems play a crucial role in the production of plastic products, food ingredients, pharmaceutical granules, chemical pellets, and recycled materials, contributing to various sectors of the economy.

As the manufacturing industry continues to evolve, extruder pelletizer systems will play an increasingly important role in driving efficiency and enabling sustainable practices. With advancements in technology and materials science, the future holds a promising outlook for the further development of these systems, propelling manufacturing processes to new heights of efficiency and productivity.