Eco-Friendly Extrusion: Plastic Recycling Extruder Machines for Sustainable Practices

Plastic pollution has become a pressing issue that the world is grappling with. With landfills overflowing and oceans choking on plastic waste, finding sustainable solutions has become imperative. This is where plastic recycling extruder machines have emerged as a game-changer. These advanced machines play a pivotal role in transforming plastic waste into valuable resources, contributing to a circular economy. In this article, we will delve into the world of plastic recycling extruder machines, exploring their functionality, benefits, and the crucial role they play in promoting sustainable practices.

Understanding Plastic Recycling Extruders

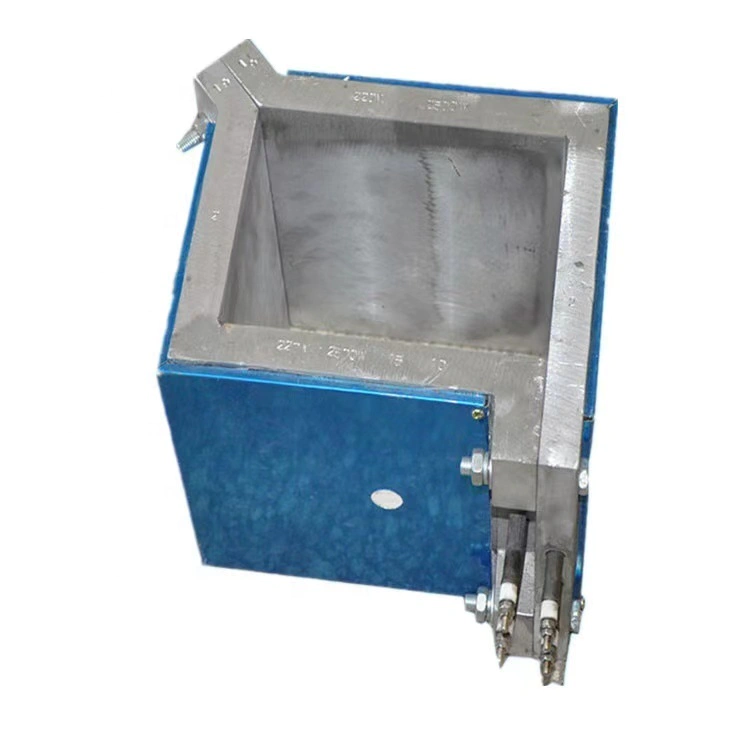

Plastic recycling extruders are machines that process plastic waste and convert it into useful products through a process called extrusion. Extrusion involves melting the plastic material and then forming it into a continuous profile by pushing it through a die. The resulting plastic product can be used for various applications, such as manufacturing new plastic items or creating materials for construction.

One of the key advantages of plastic recycling extruders is their ability to handle different types of plastic waste. Whether it is polyethylene (PE), polypropylene (PP), polystyrene (PS), or any other plastic variant, these machines can effectively process them all. This versatility makes them an invaluable asset in tackling the plastic waste crisis.

The Functionalities of Plastic Recycling Extruder Machines

Plastic recycling extruder machines offer a range of functionalities that enable efficient recycling processes. Let's explore some of the key features and processes involved:

1. Shredding and Sorting

The first step in plastic waste recycling is shredding and sorting. Plastic recycling extruders are equipped with powerful shredders that break down large plastic objects into smaller pieces. These shredded pieces are then subjected to various sorting mechanisms to separate them according to their type and color. This step is crucial in ensuring that the recycled plastic is pure and free from contaminants, allowing for high-quality end products.

2. Washing and Drying

After the shredding and sorting process, the plastic waste goes through thorough washing and drying procedures. Washing machines equipped with water jets and detergents help remove any dirt, debris, or impurities from the plastic shreds. Subsequently, the wet plastic is dried using hot air or other drying mechanisms. This step ensures that the plastic material is clean and ready for further processing.

3. Extrusion and Melt Filtration

Once the plastic is shredded, sorted, washed, and dried, it is ready for the extrusion process. The plastic flakes or granules are fed into the extruder machine, where they pass through a heated barrel. Inside the barrel, the plastic is melted at high temperatures. The molten plastic is then forced through a die, forming a continuous profile of the desired shape and size.

During the extrusion process, a melt filtration mechanism is employed to remove any remaining contaminants or impurities. This ensures that the final product is of high purity and meets the required quality standards.

4. Cooling and Granulation

After the extrusion process, the freshly formed plastic profile needs to be cooled and solidified. Cooling mechanisms such as water baths or air cooling systems are employed to rapidly cool down the plastic product. Once cooled, the continuous plastic profile is cut into smaller pieces called granules or pellets. These granules can be easily stored, transported, and used as feedstock for various manufacturing processes.

5. Optional Additives and Enhancements

In some cases, additional additives or enhancements can be incorporated into the extrusion process to improve the properties of the final plastic product. These additives can include colorants, fillers, reinforcing fibers, or even other recycled materials. By customizing the extrusion process, manufacturers can produce plastic materials with specific characteristics and performance attributes.

The Benefits of Plastic Recycling Extruder Machines

The utilization of plastic recycling extruder machines brings forth a multitude of benefits from an environmental, economic, and social perspective. Let's delve into some of the key advantages:

1. Environmental Sustainability

Plastic recycling extruder machines significantly reduce the burden on landfills and prevent plastic waste from entering natural ecosystems. By recycling and reusing plastic materials, these machines minimize the need for virgin plastic production, conserving valuable natural resources. Moreover, the energy consumption involved in recycling plastic is considerably lower than that of producing new plastic from raw materials, resulting in reduced carbon emissions.

2. Circular Economy

Plastic recycling extruder machines play a vital role in promoting a circular economy. Instead of disposing of plastic waste, these machines enable the transformation of waste into valuable resources. The recycled plastic can be used as a raw material in various industries, reducing the dependence on virgin plastic and closing the loop in the plastic production cycle.

3. Economic Opportunities

The plastic recycling industry presents significant economic opportunities. Plastic recycling extruder machines allow businesses to generate revenue by processing plastic waste and selling the recycled plastic products. Additionally, these machines contribute to job creation, as skilled technicians and operators are required to operate and maintain the recycling processes.

4. Reduction in Energy Consumption

Producing plastic from recycled materials consumes considerably less energy compared to manufacturing plastic from scratch. Plastic recycling extruder machines facilitate the recycling process by efficiently melting and shaping the plastic, reducing the overall energy requirements. This reduction in energy consumption leads to lower greenhouse gas emissions, contributing positively to environmental conservation efforts.

5. Product Diversification and Customization

Plastic recycling extruder machines offer the flexibility to produce a wide range of plastic products with varying shapes, sizes, and specifications. This enables manufacturers to meet the diverse needs of different industries and consumers. From plastic bags to automotive components, these machines can create products for various sectors, driving innovation and enhancing market competitiveness.

Conclusion

As the world grapples with the plastic pollution crisis, plastic recycling extruder machines have emerged as a powerful tool in promoting sustainable practices. With their diverse functionalities, these machines efficiently transform plastic waste into valuable resources, contributing to environmental conservation, economic growth, and a circular economy. By adopting and investing in these eco-friendly extrusion technologies, societies can pave the way towards a cleaner and greener future, where plastic waste is no longer a burden but a valuable asset.

are important in ensuring extruder machine manufacturers, and the machine is utilised by everyone from plastic extruder machine manufacturers to extruder machine manufacturers.

Nanjing Tengda Machinery Co., Ltd. is an expert manufacturer that offers top-notch plastic extruder machine manufacturers Application products in extruder machine manufacturers. The company has a a lot of experience to offer quality ensured that cater to various customer demands. Simply visit Nanjing Tengda Machinery Co., Ltd. website to learn more.

Nanjing Tengda Machinery Co., Ltd. constantly discovers the demands of global market for developing a wide range of products applied in different use.

Application, is an alternative product for plastic extruder machine manufacturers to investors and consumers who are passionate about our products or services.

Nanjing Tengda Machinery Co., Ltd. manufactures Application with innovative facilities and professional operation.