Eco-Friendly Extrusion: The Role of Plastic Pelletizing Extruders

Plastic pollution is a growing global concern, with devastating effects on the environment and ecosystems. As awareness about the detrimental impact of plastic waste increases, there is a pressing need for sustainable solutions to manage and reduce plastic waste. One such solution lies in the utilization of plastic pelletizing extruders. These innovative machines play a crucial role in the recycling industry by transforming plastic waste into reusable pellets, promoting a circular economy and mitigating the harmful effects of plastic pollution.

With the aim of elucidating the significance of plastic pelletizing extruders in eco-friendly extrusion processes, this article delves into various aspects of these machines. From their functionality and components to their environmental benefits and emerging technologies, we explore how plastic pelletizing extruders are revolutionizing the world of plastic recycling.

The Basics of Plastic Pelletizing Extruders

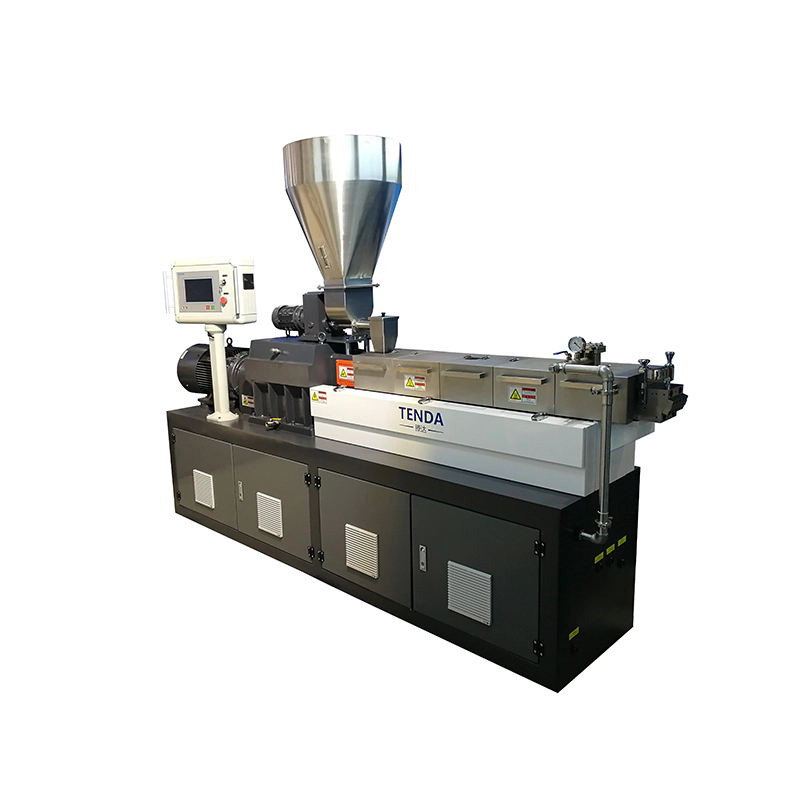

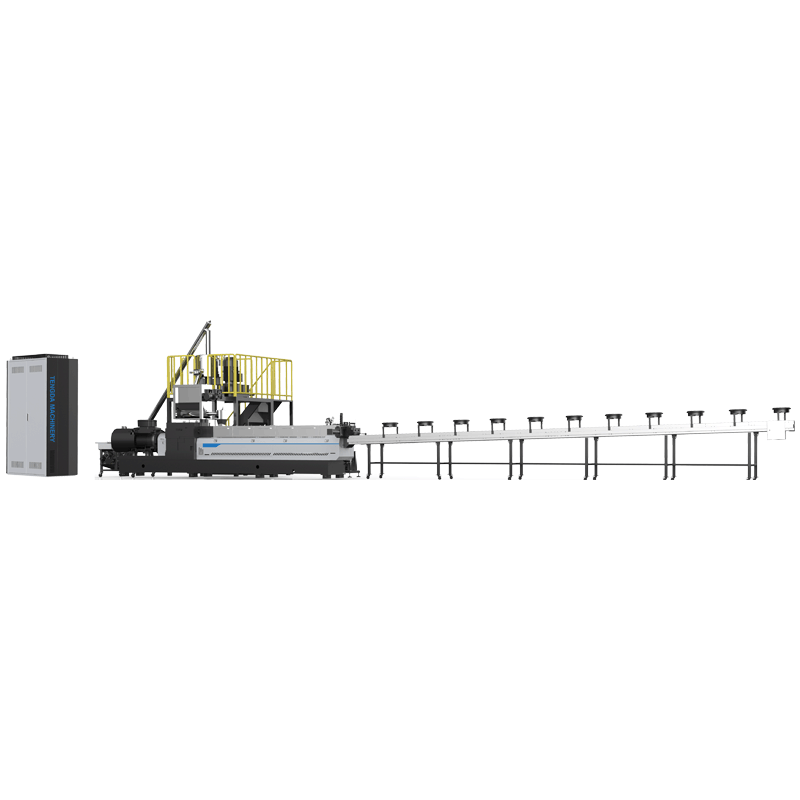

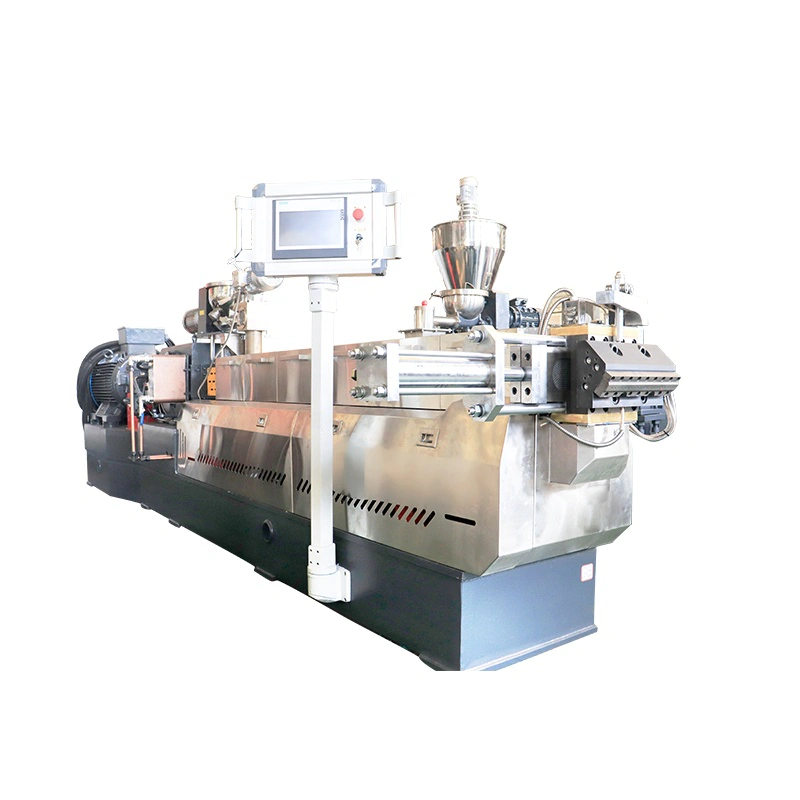

To comprehend the role of plastic pelletizing extruders, it is crucial to understand their functionality and the process they undergo. Plastic pelletizing extruders are machines designed to melt, degas, filter, and extrude plastic waste into small, uniform pellets, ready to be reused in manufacturing processes. This process is known as plastic pelletizing.

Plastic pelletizing extruders typically consist of several key components that enable efficient plastic recycling. These components include feeders, which supply the plastic waste to the extruder; an extruder barrel, where the plastic is melted and homogenized; a die plate, which shapes the molten plastic into cylindrical strands; and a cutting system, which chops the strands into uniform pellets.

The extruder barrel is a critical component of plastic pelletizing extruders. It comprises a screw that rotates within a heated barrel, creating the necessary heat and pressure to melt and process the plastic waste. The rotation of the screw ensures the proper mixing and homogenization of the melted plastic.

The Environmental Benefits of Plastic Pelletizing Extruders

Plastic pelletizing extruders offer numerous environmental benefits that make them key players in the pursuit of eco-friendly extrusion processes. Let's explore some of these benefits in detail:

1. Reduced plastic waste in landfills:

By transforming plastic waste into reusable pellets, plastic pelletizing extruders reduce the amount of plastic being sent to landfills or incinerated. This diversion of plastic waste from landfill disposal is essential in curbing pollution and conserving valuable landfill space.2. Promotion of a circular economy:

The concept of a circular economy emphasizes minimizing waste and maximizing resource efficiency. Plastic pelletizing extruders facilitate the transition towards a circular economy by transforming plastic waste into reusable materials. These recycled pellets can be utilized in the production of new plastic products, reducing the demand for virgin plastic and conserving natural resources.3. Energy savings:

Manufacturing products from recycled plastic pellets requires significantly less energy compared to the production of virgin plastic. Plastic pelletizing extruders contribute to energy savings by reducing the dependence on fossil fuels and the associated greenhouse gas emissions.4. Reduction of greenhouse gas emissions:

Plastic pelletizing extruders enable a more sustainable approach to plastic production, resulting in lower greenhouse gas emissions. By utilizing recycled plastic pellets, the need for extracting and processing fossil fuels is reduced, thereby reducing carbon emissions linked to climate change.5. Promotion of responsible waste management:

Plastic pelletizing extruders play a critical role in responsible waste management practices. By providing an efficient method of recycling plastic waste, these machines encourage proper waste disposal and discourage littering and illegal dumping. They help create a clean and sustainable environment for present and future generations.Emerging Technologies in Plastic Pelletizing Extruders

As technology advances, new innovations are constantly emerging in the field of plastic pelletizing extruders. These advancements aim to enhance the efficiency, sustainability, and versatility of the plastic recycling process. Let's explore some of the notable emerging technologies in plastic pelletizing extruders:

1. Automation and control systems:

Automated control systems are becoming increasingly prevalent in plastic pelletizing extruders. These systems integrate various sensors and monitoring devices to optimize process control, ensuring consistent and high-quality pellet production. Automation also minimizes human error and reduces energy consumption, further contributing to eco-friendly extrusion processes.2. Improved filtration and degassing:

Filtration and degassing are crucial steps in plastic pelletizing extrusion. Advanced technologies are being developed to enhance these processes, ensuring the removal of impurities, such as contaminants and moisture, from the molten plastic. This results in higher purity pellets and improves the overall quality of the recycled plastic.3. Integration of renewable energy sources:

To further reduce the environmental impact of plastic pelletizing extruders, there is a growing focus on integrating renewable energy sources into the machines. By harnessing solar, wind, or other renewable energy sources, these extruders can significantly reduce their dependence on fossil fuels and operate in a more sustainable manner.4. Adoption of artificial intelligence:

The incorporation of artificial intelligence (AI) in plastic pelletizing extruders presents exciting possibilities for optimizing the recycling process. AI algorithms can analyze data in real-time, enabling the extruders to adapt and optimize parameters such as temperature, pressure, and screw speed for improved efficiency and quality control.5. Exploration of biodegradable materials:

While plastic recycling is crucial, efforts are also underway to explore and develop biodegradable materials. Plastic pelletizing extruders are being utilized to process biodegradable plastics, enabling their transformation into reusable pellets. This development opens up new avenues for eco-friendly plastics that do not contribute to the long-term pollution caused by traditional plastics.Conclusion

Plastic pelletizing extruders are indispensable in the journey towards sustainable and eco-friendly extrusion processes. By converting plastic waste into reusable pellets, they contribute to the reduction of plastic pollution, promote a circular economy, and conserve valuable resources. With ongoing advancements in technology and the emphasis on renewable energy integration, these machines are poised to play an even more crucial role in plastic recycling. As we strive for a cleaner and greener future, the significance of plastic pelletizing extruders cannot be overstated. Let us embrace these innovative technologies and promote responsible waste management practices for the well-being of our planet and future generations.