Eco-Friendly Solutions: The Role of Recycled Plastic Extruders

As environmental concerns continue to grow, so does the need for eco-friendly solutions. One such solution gaining popularity is the use of recycled plastic extruders. These machines play a crucial role in transforming post-consumer and post-industrial plastic waste into new products, reducing the demand for virgin plastic and minimizing the impact on the environment. In this article, we will delve into the various aspects of recycled plastic extruders and explore their significance in the quest for a sustainable future.

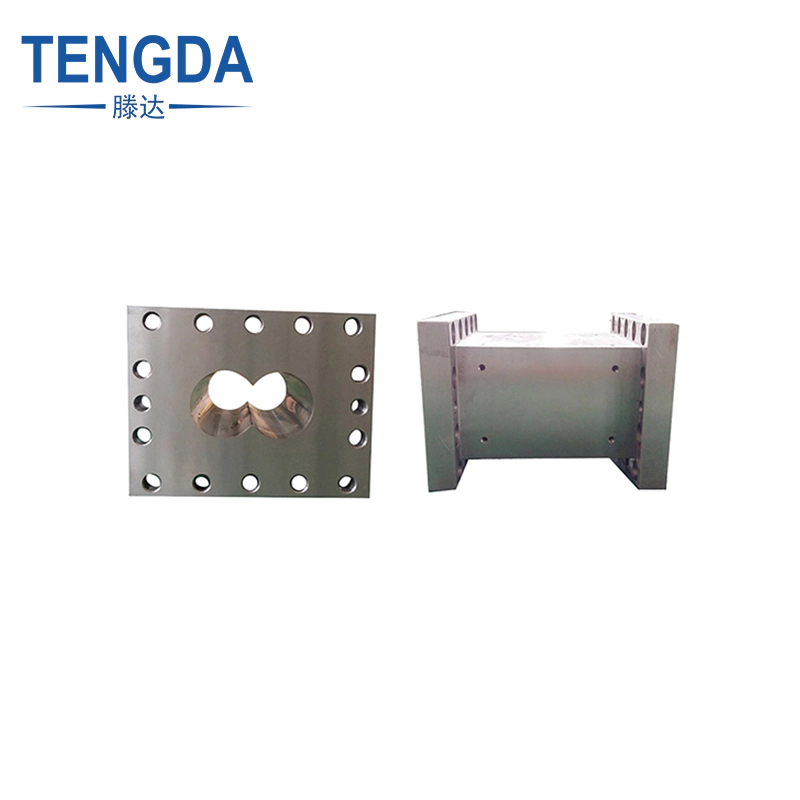

The Basics of Recycled Plastic Extruders

Recycled plastic extruders are machines used in the plastic recycling process, specifically in the extrusion phase. Extrusion is a manufacturing process in which molten plastic material is pushed through a die to create various shapes and forms. Recycled plastic extruders utilize this process to convert recycled plastic pellets or flakes into sheets, profiles, or other plastic products.

The Role of Recycled Plastic Extruders in Reducing Plastic Waste

Recycled plastic extruders play a vital role in minimizing plastic waste by transforming discarded plastic materials into usable products. The process begins by collecting plastic waste, which can include items such as bottles, packaging materials, and even automotive parts. This waste is then sorted, cleaned, and shredded into small pieces. These pieces, known as plastic pellets or flakes, are fed into the recycled plastic extruder, where heat and pressure melt them down to form a molten plastic mass. This mass is then forced through a die, taking the shape of the desired product. By utilizing recycled plastic in this way, the demand for new plastic production is reduced, leading to a significant decrease in plastic waste.

The Benefits of Using Recycled Plastic Extruders

Using recycled plastic extruders offers several advantages, both to the environment and businesses. Firstly, by recycling plastic waste, the amount of plastic ending up in landfills or oceans is reduced, thus mitigating the harmful impact on ecosystems and wildlife. Additionally, this process contributes to conserving natural resources, as it reduces the need for extracting raw materials required in the production of new plastic.

Furthermore, recycled plastic extruders provide businesses with an opportunity to engage in sustainable practices. With increasing consumer demand for environmentally friendly products, using recycled plastic can be seen as a positive marketing strategy. It not only showcases a company's commitment to environmental responsibility but also enhances its brand image and reputation.

The Challenges in Recycling Plastic

While the recycling of plastics through extrusion presents numerous benefits, it also comes with its fair share of challenges. One of the main issues is the diversity of plastic types. Plastics come in various compositions, densities, and melting points, making it challenging to process them uniformly. Each type of plastic requires specific conditions, such as temperature and pressure, to achieve optimal extrusion results. Moreover, contaminants, such as labels and adhesives, can hinder the recycling process and affect the quality of the final product. Thus, proper sorting and cleaning of plastic waste are crucial to ensure a successful extrusion process.

Overcoming Challenges with Advanced Technology

To address these challenges, advanced technologies have been developed to improve the efficiency and effectiveness of recycled plastic extruders. These technologies include automated sorting systems that use sensors, optical scanners, and artificial intelligence algorithms to identify and separate different types of plastic. Furthermore, advancements in cleaning and washing techniques help remove contaminants more effectively, ensuring higher-quality recycled plastic. Such technologies not only enhance the overall recycling process but also contribute to reducing operating costs and increasing productivity.

The Future of Recycled Plastic Extruders

Recycled plastic extruders have a promising future in the sustainable manufacturing industry. With increasing awareness of environmental issues and the need to reduce plastic waste, the demand for recycled plastic is likely to rise. This growth presents an opportunity for manufacturers of recycled plastic extruders to develop more efficient and innovative machines that cater to the specific needs of various industries.

In conclusion, recycled plastic extruders play a vital role in addressing the environmental challenges associated with plastic waste. By transforming discarded plastic materials into new products, they contribute to reducing the demand for virgin plastic production and minimize the overall impact on the environment. Despite the challenges, advancements in technology continue to improve the efficiency and effectiveness of recycled plastic extruders, paving the way for a more sustainable future. As businesses and individuals embrace eco-friendly practices, the role of recycled plastic extruders is set to become increasingly important in the fight against plastic pollution.

Nanjing Tengda Machinery Co., Ltd. is a company that offers a wide selection of . OEM and ODM services are also available to users. To know more, go to TENGDA Extruder Machine Manufacturers.

You can find a large selection of quality at TENGDA Extruder Machine Manufacturers. Go get your desired one.

Even Application are being made fine with advanced equipment.

Technology upgrades can pay for themselves quickly by improving Application and enabling employees to accomplish more in less time. It may be time to focus on plastic extruder machine manufacturers to ensure they run smoothly and efficiently.