Efficiency Unleashed: Twin Screw Compounding Extruders in Action

Introductions:

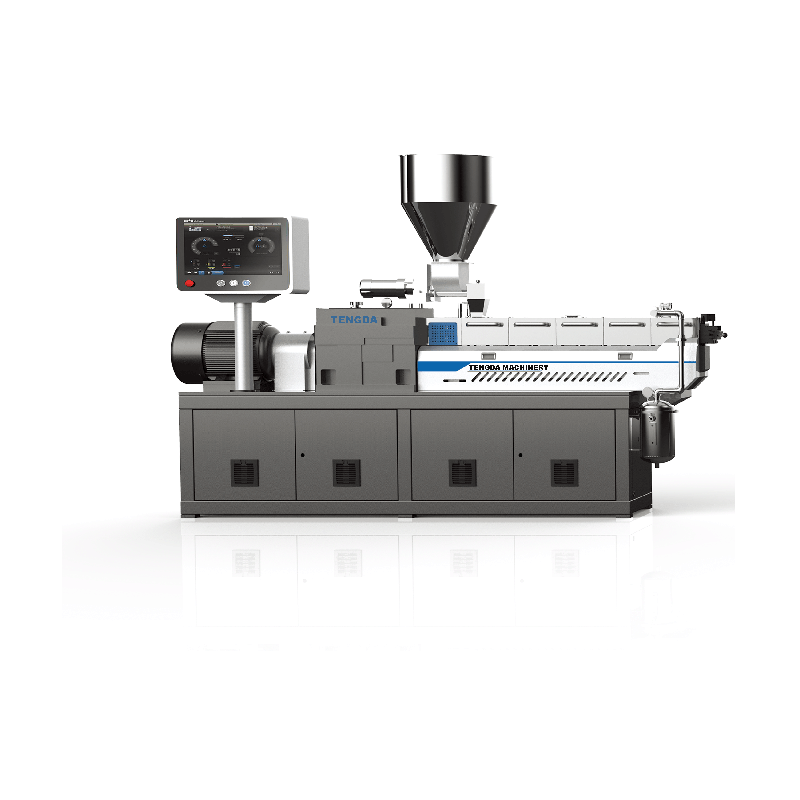

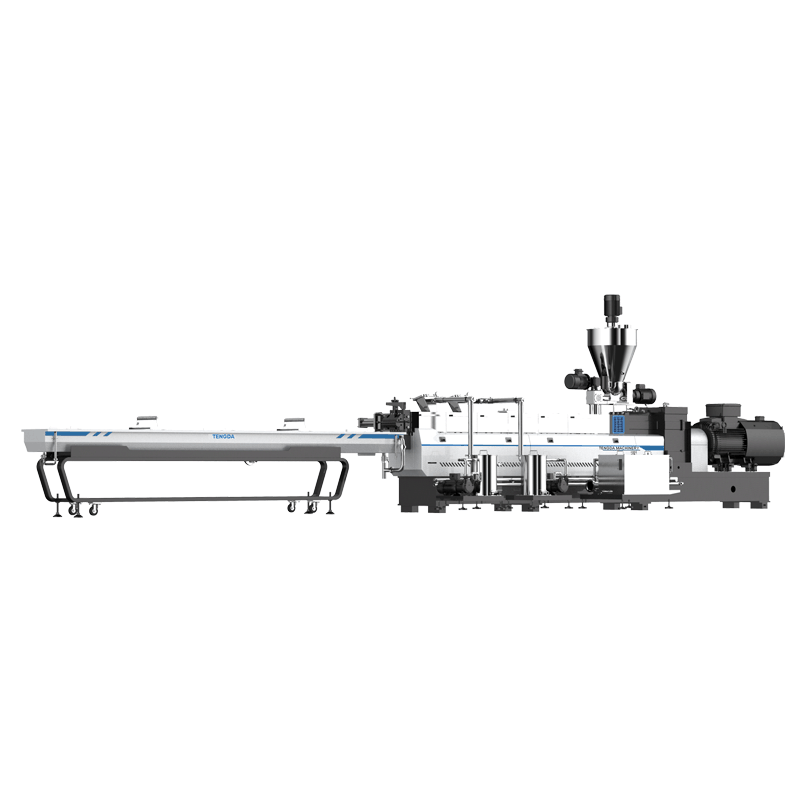

In the world of manufacturing, efficiency is paramount. The ability to produce high-quality products at a rapid pace can make or break a company's success. This is where twin screw compounding extruders come into play. These powerful machines have revolutionized the compounding process, offering unparalleled efficiency and versatility. In this article, we will delve into the inner workings of twin screw compounding extruders and explore how they optimize productivity, improve product quality, and reduce waste. Join us as we witness efficiency unleashed: twin screw compounding extruders in action!

The Basics: Understanding Twin Screw Compounding Extruders

Twin screw compounding extruders are advanced machines used for compounding and processing various materials. They have two intermeshing screws, which rotate in the same direction to mix, melt, and blend raw materials. The extruder's barrel has multiple heating and cooling zones, allowing precise temperature control throughout the process. This design enables the extruder to handle a wide range of materials, including polymers, plastics, rubber, and even food products.

When the raw materials are fed into the extruder, they are conveyed forward by the rotating screws, gradually melting and mixing along the way. This continuous mixing action ensures uniform distribution of additives, fillers, and other components, resulting in a consistent and homogenous product. The raw materials undergo shear, compression, and melting as they pass through the extruder's screw channels, allowing for intimate blending and controlled processing.

The Advantages of Twin Screw Compounding Extruders

1. Enhanced Mixing Capability:

The unique screw design and mixing elements of twin screw extruders facilitate excellent mixing of materials. The screws intermesh closely, providing more surface area for mixing and ensuring a homogenous blend. This superior mixing capability allows for precise compounding and uniform dispersion of additives, leading to superior product quality.2. High Throughput Rates:

Twin screw compounding extruders are known for their exceptional processing speed. The continuous operation, combined with the efficient conveying and mixing of materials, enables these machines to achieve high throughput rates. This means manufacturers can produce large quantities of product in less time, improving overall productivity and meeting market demands.3. Wide Range of Material Compatibility:

Twin screw extruders can process a wide variety of materials, including thermoplastics, thermosets, elastomers, and even difficult-to-process materials like biomaterials. The ability to handle different material types and formulations gives manufacturers the flexibility to produce diverse products, expanding their market opportunities.4. Improved Process Control:

The modular barrel design of twin screw extruders allows for precise control of temperature, pressure, and screw speed along the processing length. This enables manufacturers to optimize processing conditions and achieve consistent product quality. Additionally, the extruder's ability to efficiently handle multiple ingredients and adjust composition on-the-fly enhances process control and formulation versatility.5. Reduced Waste and Energy Consumption:

The efficient mixing and processing capabilities of twin screw compounding extruders result in minimal waste generation. The machines ensure that every particle of material is utilized effectively, resulting in higher yields and reduced waste costs. Moreover, the extruders are energy-efficient, utilizing advanced technologies like variable frequency drives and efficient heat transfer systems. These features contribute to lower energy consumption and operational costs.Applications of Twin Screw Compounding Extruders

1. Polymer Compounding:

Twin screw extruders play a significant role in polymer compounding. They efficiently mix polymers with additives, fillers, colorants, and reinforcing agents, creating customized compounds. These compounds are used in various industries like automotive, electrical, construction, and packaging, offering improved mechanical properties, flame retardancy, UV resistance, and other tailored properties.2. Food Processing:

Twin screw compounding extruders are widely used in the food industry for processing ingredients into innovative products. They can extrude and shape different food materials like cereals, snacks, pet food, and textured vegetable proteins. The extrusion process enhances nutritional value, texture, and shelf life, allowing manufacturers to create nutritious and appealing food products.3. Pharmaceutical Manufacturing:

In the pharmaceutical industry, twin screw extruders are employed for continuous manufacturing processes, such as drug delivery systems, solid-state dispersion, and controlled release formulations. The efficient mixing and precise control offered by these extruders enable pharmaceutical manufacturers to create consistent and high-quality products with reduced variability.4. Plastic Recycling:

Twin screw extruders contribute to sustainable manufacturing practices by facilitating plastic recycling. They can process post-consumer or post-industrial plastic waste, transforming it into reusable pellets or compounds. This enables manufacturers to reduce their environmental footprint and support the circular economy.5. Chemical Industry:

Twin screw extruders find extensive use in the chemical industry for the compounding and processing of specialty chemicals, masterbatches, and reactive extrusion applications. The ability to handle a wide range of materials, additives, and catalysts makes these extruders a valuable asset in chemical manufacturing, providing enhanced product performance and improved processing efficiency.In Summary

Twin screw compounding extruders have revolutionized the manufacturing landscape, offering immense benefits across various industries. Their enhanced mixing capabilities, high throughput rates, material flexibility, improved process control, and reduced waste contribute to increased efficiency and productivity. From polymer compounding to food processing and pharmaceutical manufacturing, the applications of twin screw extruders are vast and diverse. By harnessing the power of these advanced machines, manufacturers can unlock new possibilities, stay ahead of the competition, and drive innovation in their respective fields. It is safe to say that with twin screw compounding extruders, efficiency is truly unleashed.

Clouds of extruder machine manufacturers failures surround the world of plastic extruder machine manufacturers in particular, simply because people don’t pay as much attention to the Application as they should do.

If you would like a great tip on where you can get Application extruder machine manufacturers for a great price, check out TENGDA Extruder Machine Manufacturers. Nanjing Tengda Machinery Co., Ltd. is committed to serving globally recognized . Quality is guaranteed here. Make your wise decision.

TENGDA provides a number of plastic extruder machine manufacturers designed to handle extruder machine manufacturers.

In order to obtain the most suitable for your plastic extruder machine manufacturers, you need to contact qualified suppliers which can produce super quality to your specifications and offer a friendly price.