Enhancing Product Quality with a Modern Sheet Extruder Machine

Enhancing Product Quality with a Modern Sheet Extruder Machine

Introduction

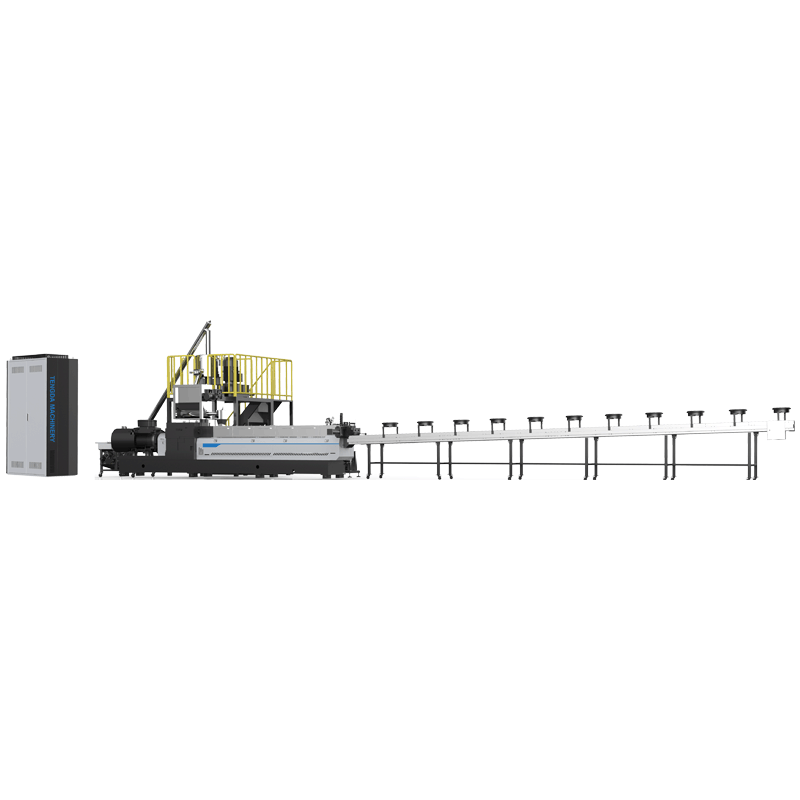

In today's competitive market, maintaining high product quality is crucial for any manufacturer. One of the key factors that contribute to product quality is the production process, and in particular, the machinery used. A modern sheet extruder machine is one such equipment that plays a vital role in enhancing the overall quality of the final product. This article explores the various ways in which a modern sheet extruder machine can improve product quality.

1. Improved Material Handling

The first aspect where a modern sheet extruder machine excels is in material handling. Traditional extruders often struggle with consistent material feeding, resulting in variations in the quality of the sheet produced. However, with advanced automation and control systems, modern extruders ensure precise material feeding. This ensures an even flow of the raw material, resulting in uniform thickness and improved quality of the sheet.

2. Enhanced Extrusion Process

Another crucial factor that affects product quality is the extrusion process itself. Modern sheet extruder machines are designed to optimize this process, ensuring a higher level of control and precision. The extrusion barrel, equipped with modern heating and cooling systems, allows for accurate temperature control throughout the process. This precision facilitates the production of sheets with consistent properties, such as thickness, rigidity, and transparency, leading to improved overall product quality.

3. Advanced Cooling Mechanism

Achieving the desired cooling rate is critical during the sheet extrusion process. Rapid cooling helps prevent warping, distortion, or other defects that can occur as the sheet solidifies. A modern sheet extruder machine incorporates advanced cooling mechanisms, such as chilled rolls or water baths, which enable controlled and efficient cooling of the sheet. This feature significantly contributes to the superior quality of the final product.

4. Innovative Technology for Sheet Formation

The technology used for sheet formation has evolved significantly with modern sheet extruder machines. These machines employ advanced dies and calibration systems that ensure precise formation of the sheet. The die design plays a crucial role in determining the sheet's thickness profile, surface quality, and overall accuracy. With improved die technology, modern extruders achieve exceptional control over sheet formation, resulting in sheets with consistent thickness and excellent surface finish.

5. Automation and Process Control

Automation and process control are integral parts of modern sheet extruder machines. These machines are equipped with advanced control systems that allow manufacturers to monitor and regulate various aspects of the extrusion process. Real-time monitoring of key parameters, including melt temperature, line speed, cooling rate, and sheet thickness, ensures optimal process conditions and uniform product quality. Moreover, automation reduces the dependence on manual intervention, minimizing the chances of errors or inconsistencies during production.

Conclusion

In conclusion, a modern sheet extruder machine plays a vital role in enhancing product quality. Its improved material handling capabilities, enhanced extrusion process, advanced cooling mechanisms, innovative sheet formation technology, and automation features collectively contribute to superior product quality. Manufacturers who invest in modern sheet extruder machines can not only improve the consistency and precision of their sheet production but also ensure customer satisfaction by delivering high-quality products. As technology continues to advance, the impact of these machines on enhancing product quality is expected to grow further, making them an indispensable part of manufacturing processes across various industries.

Nanjing Tengda Machinery Co., Ltd. who is highly knowledgeable about manufacturing as well as selling and confident in our ability to create finest products as Application extruder machine manufacturers.

We are an experienced supplier of and have gained good reputaion among global customers. With a wide range of in offer, we can customize according to your requirement. Send us your enquiry at TENGDA Extruder Machine Manufacturers.

These plastic extruder machine manufacturers Application have made the life easier. The best feature of the is its extruder machine manufacturers.

According to the latest social survey, more than 50 percent of consumers (across all age demographics) follow a brand before purchasing a product. Therefore, TENGDA's content can make or break a customer's decision to conduct business with you.

Nanjing Tengda Machinery Co., Ltd. needs to ensure we're resolving customer issues as quickly as possible. By doing so, it leads to positive customer experiences and brand loyalty.