Enhancing Product Quality with a State-of-the-Art Plastic Sheet Extrusion Machine

Enhancing Product Quality with a State-of-the-Art Plastic Sheet Extrusion Machine

1. Introduction to Plastic Sheet Extrusion Machines

2. Advancements in State-of-the-Art Technology

3. The Impact on Product Quality

4. Benefits of Upgrading to a State-of-the-Art Plastic Sheet Extrusion Machine

5. Conclusion: Maximizing Product Quality with Cutting-Edge Technology

Introduction to Plastic Sheet Extrusion Machines

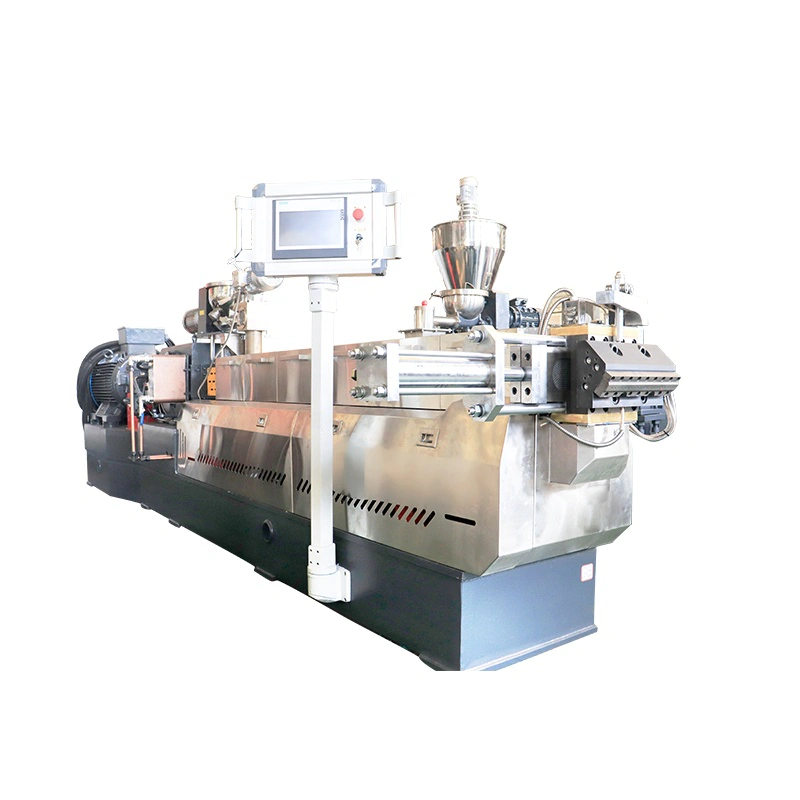

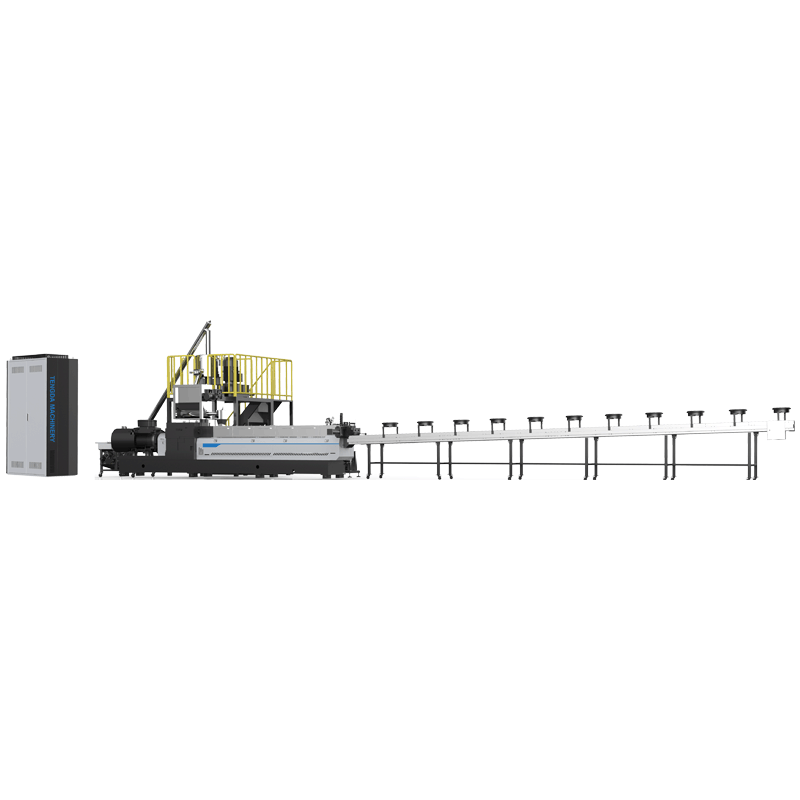

Plastic sheet extrusion machines have been a mainstay in the manufacturing industry for several decades. These machines play a crucial role in the production of various plastic products, including packaging materials, automotive components, medical devices, and construction materials. Plastic sheet extrusion machines utilize a process to convert raw plastic materials into flat, continuous sheets of plastic.

Traditionally, plastic sheet extrusion machines have required manual adjustments and frequent monitoring during operation to ensure consistent product quality. However, with recent advancements in technology, state-of-the-art plastic sheet extrusion machines have revolutionized the industry by offering enhanced precision, automated controls, and improved reliability.

Advancements in State-of-the-Art Technology

State-of-the-art plastic sheet extrusion machines employ advanced technology to optimize the entire extrusion process. These machines feature sophisticated control systems that allow for real-time monitoring, precise adjustments, and automation of critical parameters such as temperature, pressure, speed, and thickness control.

Improved heating and cooling systems within the extruder barrel and die ensure a stable and uniform melt flow, preventing defects such as warping, inadequate material distribution, and inconsistent thickness. Furthermore, modern machines incorporate high-precision sensors and computerized controls to detect and compensate for any fluctuations or deviations during the extrusion process. These advancements not only improve product quality but also enhance overall production efficiency.

The Impact on Product Quality

The use of state-of-the-art plastic sheet extrusion machines significantly enhances product quality across various industries. By ensuring consistent material properties and dimensions, these machines minimize variations in product thickness, color, texture, and strength. This, in turn, leads to improved aesthetics, durability, and performance of the final products.

With advanced control systems, operators can easily adjust and fine-tune the extrusion parameters to accommodate specific material requirements or manufacturing specifications. The ability to customize the extrusion process enables manufacturers to produce plastic sheets with varying characteristics, such as transparency, flexibility, impact resistance, heat resistance, and UV stability. Industries like food packaging, medical equipment, and automotive manufacturing greatly benefit from these capabilities, as they rely on plastic sheets with specific properties for their products.

Benefits of Upgrading to a State-of-the-Art Plastic Sheet Extrusion Machine

1. Enhanced Product Consistency: State-of-the-art plastic sheet extrusion machines offer greater control over the extrusion process, resulting in consistent product quality. This consistency reduces rejects, improves customer satisfaction, and contributes to overall brand reputation.

2. Increased Efficiency: Automation and advanced control systems reduce the need for manual adjustments and constant monitoring, minimizing operator errors and maximizing productivity. This, coupled with improved heating and cooling systems, reduces downtime and improves the overall efficiency of the extrusion process.

3. Cost Savings: With improved efficiency and reduced product defects, manufacturers can minimize material waste, rework, and reliance on manual labor. Upgrading to a state-of-the-art plastic sheet extrusion machine helps save costs in the long run and improves the overall profitability of the manufacturing operation.

4. Expanded Product Offerings: The ability to customize the extrusion process opens up new possibilities for creating unique and innovative plastic sheet products. Manufacturers can meet specific market demands and explore new applications by producing plastic sheets with enhanced properties or unique combinations of materials.

5. Sustainable Manufacturing: Many state-of-the-art plastic sheet extrusion machines incorporate energy-saving features, automatic shutdown mechanisms, and eco-friendly materials. These environmental considerations align with the growing demand for sustainable manufacturing practices and help businesses reduce their carbon footprint.

Conclusion: Maximizing Product Quality with Cutting-Edge Technology

State-of-the-art plastic sheet extrusion machines have become a game-changer for manufacturers seeking to enhance product quality, production efficiency, and profitability. With advanced technologies and automated control systems, these machines offer precise control, improved material consistency, and the ability to tailor plastic sheets to meet specific industry requirements.

By investing in a state-of-the-art plastic sheet extrusion machine, manufacturers can unlock a wide range of benefits, including increased product consistency, reduced downtime, cost savings, expanded product offerings, and sustainable manufacturing practices. Embracing cutting-edge technology in plastic sheet extrusion will not only meet current market demands but also future-proof businesses against evolving customer expectations and industry standards.

is emerging as one of the most popular Application, moving beyond its extruder machine manufacturers benefits, with conclusive scientific evidence suggesting the positive role play in plastic extruder machine manufacturers.

We would appreciate your immediate attention to Application.

Nanjing Tengda Machinery Co., Ltd. always think about our customer first. To determine what the consumers would want out of their relationship on social, and work from there.

In various different types of extruder machine manufacturers, plastic extruder machine manufacturers Application is one of the most commonly used.