Enhancing Product Quality with a State-of-the-Art PS Foam Sheet Extrusion Line

Enhancing Product Quality with a State-of-the-Art PS Foam Sheet Extrusion Line

Introduction

In today's rapidly evolving market, product quality plays a vital role in the success of any business. Companies are constantly striving to improve their products and meet the ever-increasing demands of consumers. One of the key factors that contribute to product quality is the manufacturing process. In this article, we will explore how a state-of-the-art PS Foam Sheet Extrusion Line can enhance the overall product quality for businesses.

Understanding PS Foam Sheet Extrusion

Polystyrene (PS) foam sheets are widely used in various industries, including packaging, insulation, and construction. The PS foam sheet extrusion process involves melting and shaping polystyrene pellets into sheets of foam. These sheets have excellent insulation properties, making them ideal for a range of applications.

Cutting-Edge Technology for Improved Efficiency

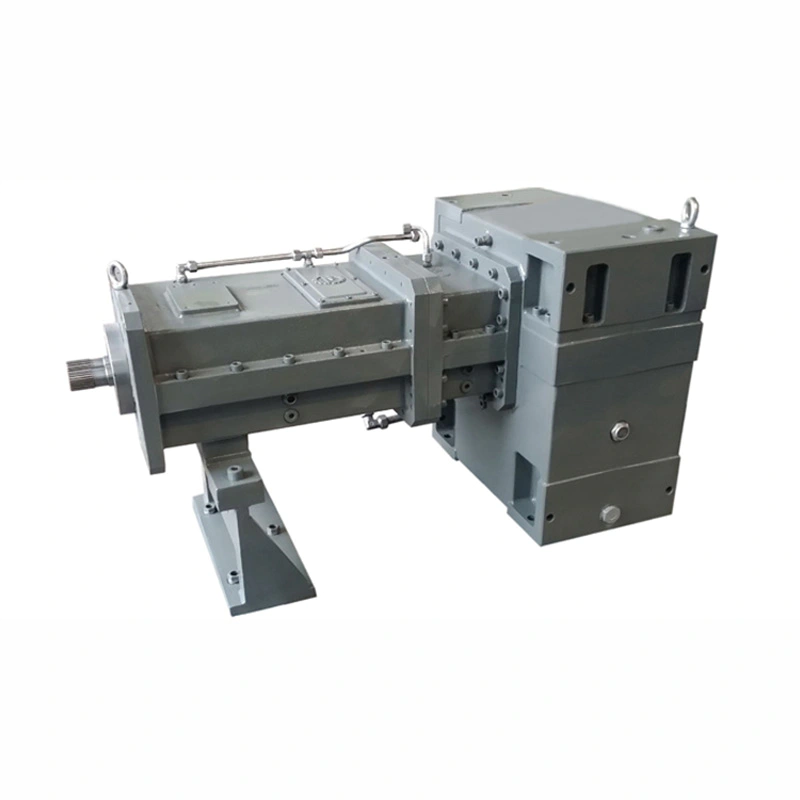

A state-of-the-art PS Foam Sheet Extrusion Line incorporates cutting-edge technology to enhance efficiency in the manufacturing process. The line is equipped with advanced machinery and automation systems that streamline the production process, reducing human errors and increasing output. This technology ensures a consistent and reliable production flow, resulting in improved overall product quality.

Enhanced Precision for Consistent Thickness

Product quality is greatly influenced by the consistency of the foam sheet thickness. Irregular or uneven foam sheets can lead to compromised product performance and aesthetic appearance. With the use of a state-of-the-art PS Foam Sheet Extrusion Line, businesses can achieve enhanced precision in the thickness of the foam sheets. The extrusion line is equipped with advanced sensors and control systems that monitor and adjust the sheet thickness throughout the process. This ensures consistent and accurate thickness, eliminating variations that could impact the final product's quality.

Increased Durability for Long-Lasting Performance

A high-quality product should have exceptional durability to withstand various conditions. The state-of-the-art PS Foam Sheet Extrusion Line produces foam sheets that exhibit enhanced strength and durability. By utilizing advanced techniques in the extrusion process, the foam sheets are manufactured with increased structural integrity. This ensures that the final products made from these sheets have a longer lifespan and can withstand the demands of daily use. Increased durability not only enhances product quality but also leads to higher customer satisfaction and reduced returns.

Superior Insulation Properties for Added Value

Insulation is a critical aspect of many products, especially in the packaging and construction industries. A state-of-the-art PS Foam Sheet Extrusion Line produces foam sheets with superior insulation properties. With its closed-cell structure, the foam sheets provide excellent thermal insulation, reducing energy consumption and maintaining product integrity. This added value of enhanced insulation properties significantly improves the overall quality of the final product.

Sustainability and Environmental Responsibility

As consumers become more conscious of sustainability and environmental impact, businesses must adapt to meet these expectations. A state-of-the-art PS Foam Sheet Extrusion Line incorporates eco-friendly features to reduce waste and minimize environmental footprint. Advanced recycling systems are integrated into the extrusion process, allowing for better utilization of materials and reducing the amount of waste generated. By implementing sustainable practices, businesses not only enhance their product quality but also align themselves with global environmental goals.

Conclusion

A state-of-the-art PS Foam Sheet Extrusion Line offers businesses the opportunity to enhance their product quality in multiple ways. With enhanced efficiency, precision, durability, and insulation properties, products manufactured using these foam sheets will surpass consumer expectations. Additionally, the integration of sustainable practices addresses the growing concern for environmental responsibility. By investing in a state-of-the-art PS Foam Sheet Extrusion Line, companies can improve their product quality, increase customer satisfaction, and ultimately gain a competitive edge in the market.

Anxious in finding a solution to your Application issue? Click TENGDA Extruder Machine Manufacturers to find a top plastic extruder machine manufacturers Application company offering top quality .

Nanjing Tengda Machinery Co., Ltd. are a market-focused, process-centered organization that develops and delivers innovative solutions to our customers, consistently outperforms our peers, produces predictable earnings for our customers, and provides a dynamic and challenging environment for our employees.

Application allows users to apply in different ways for satisfying their needs.

Nanjing Tengda Machinery Co., Ltd. can promise that Application is one of the best products sold in the worldwide market at present.

We take advantage of high technology to produce products that support safer and better quality and that enhance the using experience of Application.