Extruder Plastic Recycling: Maximizing Your Output and Minimizing Your Costs

Plastic waste has become a pressing issue in today's society, with millions of tons of plastic ending up in landfills and oceans every year. To tackle this problem, recycling has emerged as a crucial solution. However, traditional recycling methods often fall short when it comes to processing large quantities of plastic efficiently and economically. This is where extruder plastic recycling comes into play. With its ability to maximize output while minimizing costs, extruder plastic recycling is revolutionizing the way we approach plastic waste management.

Why Extruder Plastic Recycling?

Extruder plastic recycling offers several key advantages over traditional recycling methods. The process involves melting down plastic waste, transforming it into a molten state and then reforming it into usable products. This method allows for a significantly higher output compared to other recycling techniques. Extruder machines can process a wide range of plastic materials, including various types of polymers, making them versatile and adaptable to different recycling needs.

Additionally, extruder plastic recycling is known for its cost-effectiveness. The process has the ability to recover more plastic per hour, resulting in higher productivity and reduced operating costs. The efficiency of extruder machines enables businesses to achieve economies of scale and maximize their return on investment. By effectively recycling plastic waste, companies can not only contribute to the environment but also generate revenue from selling the recycled products.

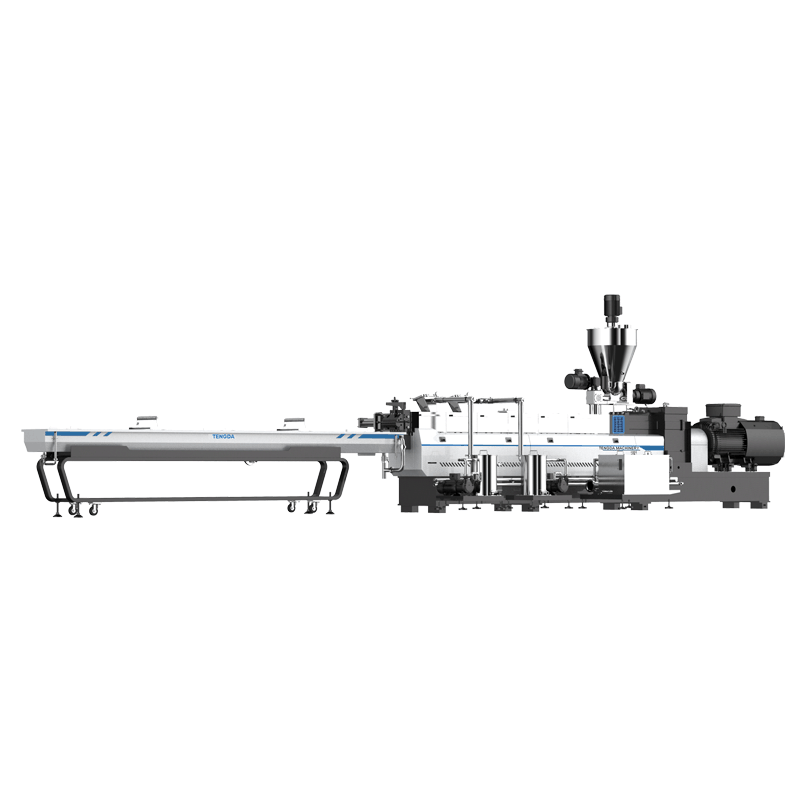

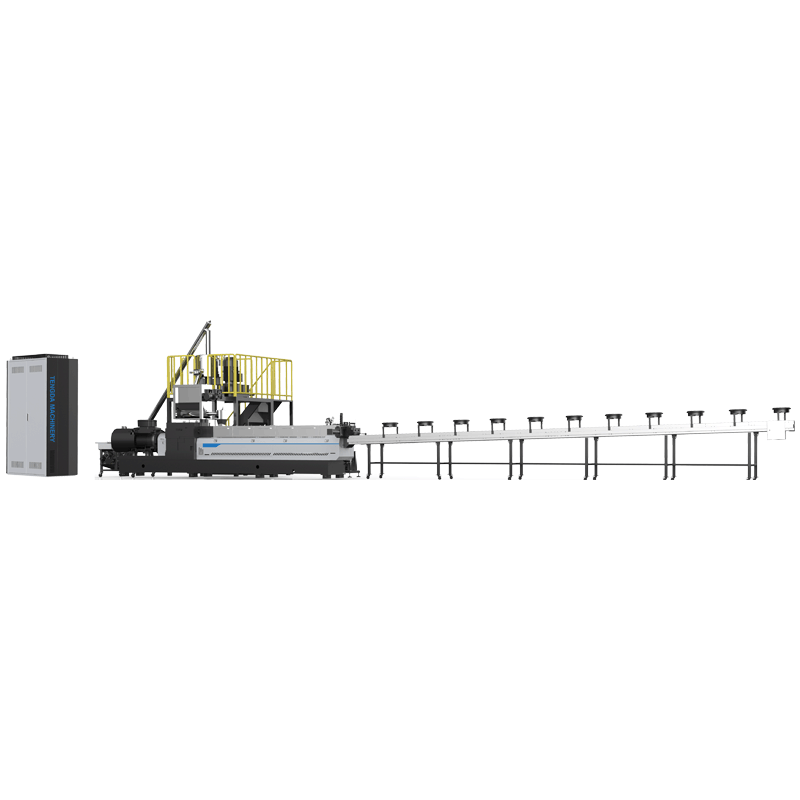

The Components of an Extruder Plastic Recycling System

An extruder plastic recycling system consists of several key components, each with its own role in the recycling process.

1. Material Feeding System: The material feeding system is responsible for supplying the plastic waste into the extruder machine. It typically includes a conveyor belt or an automated feeding mechanism to ensure a continuous and consistent flow of materials. Proper material feeding is essential for maintaining the operational efficiency of the extruder system.

2. Extruder Machine: At the heart of the plastic recycling system lies the extruder machine. This equipment consists of a barrel, a screw, and a motor. The barrel houses the screw, which rotates and pushes the molten plastic through a die to shape it into the desired form. The extruder machine's design and specifications may vary depending on the specific recycling requirements and the type of plastic being processed.

3. Heating and Cooling Systems: To melt the plastic waste, the extruder machine employs a heating system using electric heaters. Control systems are in place to maintain the optimal temperature throughout the recycling process. Cooling systems, such as water or air cooling, are also integrated into the extruder machine to solidify the molten plastic and ensure its proper formation.

4. Screen Changer: The screen changer plays a crucial role in the extruder plastic recycling system by removing impurities and filtering the molten plastic. This component prevents contaminants such as dirt, metal particles, or residual polymers from affecting the quality of the final recycled plastic.

5. Product Forming Machinery: Once the plastic is melted and purified, it needs to be shaped into the desired product. This is achieved through various forming mechanisms, including injection molding, blow molding, or pelletizing. The choice of forming machinery depends on the intended application of the recycled plastic.

The Benefits of Extruder Plastic Recycling

Extruder plastic recycling offers numerous benefits that have made it a preferred method for businesses and industries worldwide.

1. High Output: One of the major advantages of extruder plastic recycling is its ability to process plastic waste at a high output rate. Extruder machines can handle large volumes of plastic, resulting in efficient and speedy recycling operations. This enables businesses to meet the ever-increasing demand for recycled plastic products in the market.

2. Cost Savings: By maximizing output, extruder plastic recycling allows businesses to reduce their operational costs significantly. With higher productivity, companies can achieve economies of scale and optimize their resource utilization. This, in turn, leads to cost savings and improved financial performance.

3. Quality Control: The extruder plastic recycling process offers superior control over the quality of the recycled plastic. Through various parameters and controls, businesses can ensure that the end product meets the required specifications and industry standards. This level of quality control increases the market value of the recycled plastic and enhances customer satisfaction.

4. Environmental Sustainability: Perhaps the most important benefit of extruder plastic recycling is its positive impact on the environment. By diverting plastic waste from landfills and oceans, the process helps reduce pollution and conserve natural resources. Furthermore, the production of recycled plastic requires less energy and emits fewer greenhouse gases compared to virgin plastic production, further contributing to environmental sustainability.

5. Market Opportunities: The demand for recycled plastic products is growing rapidly, driven by increased environmental awareness and regulatory pressure. Extruder plastic recycling offers businesses a chance to tap into this lucrative market and capitalize on the rising demand. By adopting extruder plastic recycling methods, companies can expand their product offerings and create new revenue streams.

In Conclusion

Extruder plastic recycling has emerged as a game-changer in the world of plastic waste management. With its ability to maximize output, minimize costs, and contribute to environmental sustainability, extruder plastic recycling offers a compelling solution to the plastic pollution crisis. By investing in this innovative recycling technique, businesses can not only improve their bottom line but also make a positive and lasting impact on the planet. It is time for companies to embrace extruder plastic recycling and pave the way for a more sustainable future. Let us join hands in this endeavor and create a world where plastic waste is transformed into valuable resources, all while protecting our planet and future generations.

Nanjing Tengda Machinery Co., Ltd. promises that we will manufature our products in accordance with the strictest quality standards.

Are you interested in buying ? We also have all kinds of in offer. Visit TENGDA Extruder Machine Manufacturers to know more and order, we have them at pocket friendly prices.

Obviously, financial return is important in manufacturing Application, but I think that's not enough. I think many customers want to support something they really believe in.

The unique connections between Applicationmanufacturing and customers happen when you find ways to relate on a more personal and engaging level that goes beyond a product.

Nanjing Tengda Machinery Co., Ltd. always believes that the average profitability of our company is sufficient.