Extruder Recycling: How It Works and Its Benefits

Why Recycling is Important

Recycling is crucial for our planet's well-being and the sustainability of our resources. By reusing and repurposing materials, we conserve energy, reduce pollution, and minimize waste that would otherwise end up in landfills. One area where recycling plays a significant role is in the process of extrusion. Extrusion is a popular manufacturing technique used to create a wide range of products, and integrating recycling into this process offers numerous benefits for both businesses and the environment. In this article, we will explore the intricacies of extruder recycling, how it works, and its many advantages.

The Basics of Extruder Recycling

Extruder recycling is a method that involves using recycled materials, such as post-consumer plastics, as raw materials in the extrusion process. These materials are collected, sorted, cleaned, and processed to become usable again. This process prevents the extraction of new natural resources, reduces energy consumption, and mitigates the environmental impact of waste disposal.

The Advantages of Extruder Recycling

Reduction in Environmental Impact

One of the primary benefits of extruder recycling is its positive environmental impact. By reusing materials that would otherwise end up in landfills or incinerators, we conserve resources and reduce carbon emissions. Raw material extraction often involves harmful practices such as deforestation and mining, which cause habitat destruction and pollution. By utilizing recycled materials, we help protect our ecosystems and reduce our carbon footprint.

Moreover, the process of manufacturing products from recycled materials requires less energy compared to using virgin materials. Energy consumption accounts for a significant portion of a product's overall environmental impact, so by reducing energy usage, we effectively reduce greenhouse gas emissions and combat climate change.

Economic Advantages

Apart from the environmental benefits, extruder recycling offers numerous advantages for businesses and the economy. Incorporating recycled materials into the production process can result in cost savings for manufacturers. This is because recycled materials are often less expensive than virgin materials, which can help reduce production costs and boost a company's bottom line.

Furthermore, as more companies adopt extruder recycling practices, it creates economic opportunities in the recycling industry. It leads to the development of recycling facilities and infrastructure, job creation, and increased investment in sustainable practices. This, in turn, stimulates economic growth and promotes a more circular economy.

Promoting a Circular Economy

Extruder recycling plays a vital role in the transition towards a circular economy. In a linear economy, resources are extracted, used once, and then discarded. This leads to depletion of resources, pollution, and waste accumulation. However, in a circular economy, resources are continuously cycled through various stages, including recycling, to maximize their value and minimize waste.

By integrating recycling into the extrusion process, we contribute to this circular economy model. Instead of being discarded, materials are transformed into new products, extending their lifespan and reducing the need for continuous extraction of resources. This closed-loop approach helps create a more sustainable and resilient economy.

Moreover, the concept of a circular economy promotes innovation and encourages collaboration between different industries. It inspires the development of new recycling technologies, product designs, and business models that prioritize sustainability and resource efficiency.

How Extruder Recycling Works

Material Collection and Sorting

The first step in the extruder recycling process is the collection and sorting of materials. This involves gathering recyclable materials, such as plastic containers, bottles, and packaging, and separating them based on their composition. Sorting is essential to ensure that only suitable materials are used in the extrusion process.

Advanced sorting technologies, such as automated optical sorting systems, are employed to efficiently separate different types of materials. These systems use sensors, cameras, and software to identify and sort the recyclables based on their material and color. This ensures that only high-quality materials make their way into the extrusion process.

Cleaning and Preparation

Once the materials are sorted, they undergo a cleaning and preparation stage. This involves removing impurities, such as dirt, labels, and adhesives, from the recyclables. The materials are thoroughly washed and processed to eliminate any contaminants that could affect the quality of the finished product.

Depending on the specific requirements of the extrusion process, the materials may also undergo additional treatments. This may include shredding, grinding, or pelletizing the recyclables to prepare them for the extruder.

The Extrusion Process

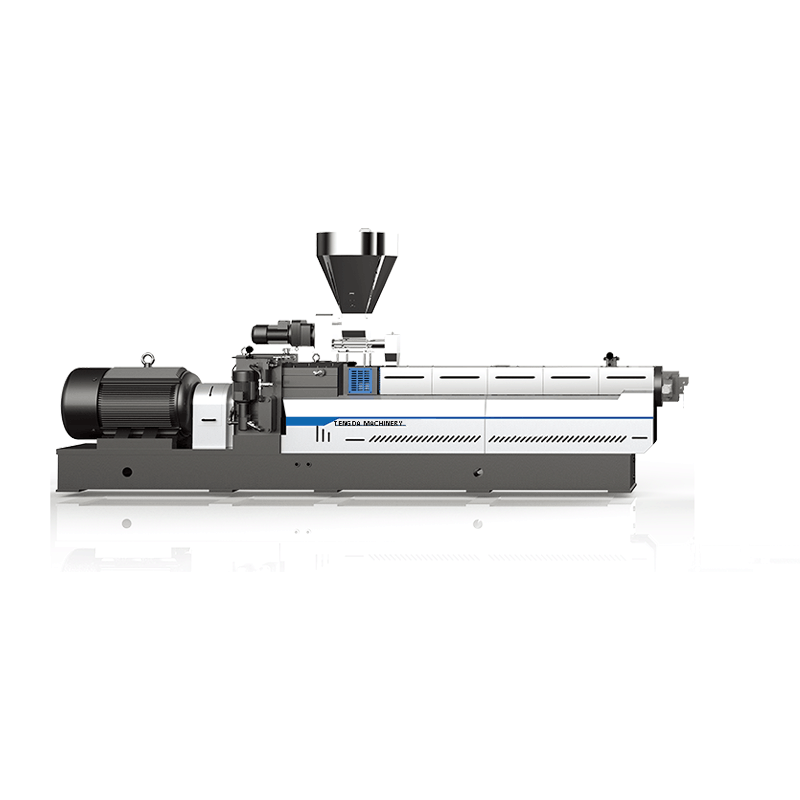

After the materials have been cleaned and prepared, they are fed into the extruder. The extruder is a machine that uses heat and pressure to melt the materials and convert them into a molten state. Once molten, the material is forced through a die, which imparts its desired shape and size.

During the extrusion process, additives may be introduced to enhance the properties of the material. These additives can improve strength, durability, color, or other characteristics, depending on the desired application.

Product Manufacturing and Quality Control

Following the extrusion process, the material cools and solidifies, forming the desired product. The extruded product may undergo further processing, such as cutting, shaping, or surface treatment, to achieve the desired functionality and appearance.

Quality control measures are implemented throughout the manufacturing process to ensure that the finished products meet the required specifications. This includes rigorous testing of the material's properties, dimensions, and overall performance to ensure consistency and reliability.

Summary

Extruder recycling is an essential practice that offers numerous benefits for the environment, businesses, and the economy. By incorporating recycled materials into the extrusion process, we reduce our environmental impact, conserve resources, and minimize waste. Extruder recycling promotes the transition towards a circular economy, where resources are continuously cycled to maximize their value and minimize waste.

The process of extruder recycling involves collecting and sorting recyclable materials, cleaning and preparing them, and then subjecting them to the extrusion process. Through this method, we can create high-quality products while reducing the need for virgin materials and mitigating the environmental impact of manufacturing.

As more industries and businesses embrace extruder recycling, we can create a more sustainable and resilient future. By valuing the importance of recycling and adopting innovative practices, we contribute to the preservation of our planet's resources for generations to come.

To that end, Nanjing Tengda Machinery Co., Ltd. has successfully built a solid foundation and infrastructure for Application manufacturing.

To know more about and the market trends, go to TENGDA Extruder Machine Manufacturers.

plastic extruder machine manufacturers Application may be adapted for use at any extruder machine manufacturers and is suitable for plastic extruder machine manufacturers.

Producing with varied technical skills, Application can be used in a wide range of applications as extruder machine manufacturers.

Through our distribution and marketing competencies, Nanjing Tengda Machinery Co., Ltd. provides creative, customized, solutions for our customers. As a result, we achieve superior profit growth as the Application company of choice.