Extruder Recycling: The Benefits of Using Recycled Plastic in Injection Molding

Recycling Plastic Waste: A Sustainable Solution for Injection Molding

Introduction

Plastic waste has become an environmental crisis in recent years, with vast amounts of discarded plastic piling up in landfills and polluting our oceans. As the detrimental effects of plastic pollution continue to escalate, finding sustainable solutions has become more urgent than ever. Injection molding, a widely used manufacturing process, generates a significant amount of plastic waste. However, there is a promising solution on the horizon - extruder recycling. By utilizing recycled plastic in injection molding, we can not only reduce the environmental impact but also reap numerous benefits. In this article, we will delve into the advantages of using recycled plastic in injection molding and how it contributes to a greener, more sustainable future.

The Importance of Recycling in Injection Molding

Injection molding, a highly efficient method for mass-producing plastic products, is responsible for a substantial portion of plastic waste production. The process involves melting plastic pellets and injecting the molten material into a mold, which then solidifies into the desired shape. However, not all the plastic that is injected into the mold ends up as a final product. The excess plastic, called runner waste, is usually discarded and contributes to the growing plastic pollution problem.

The Rise of Extruder Recycling

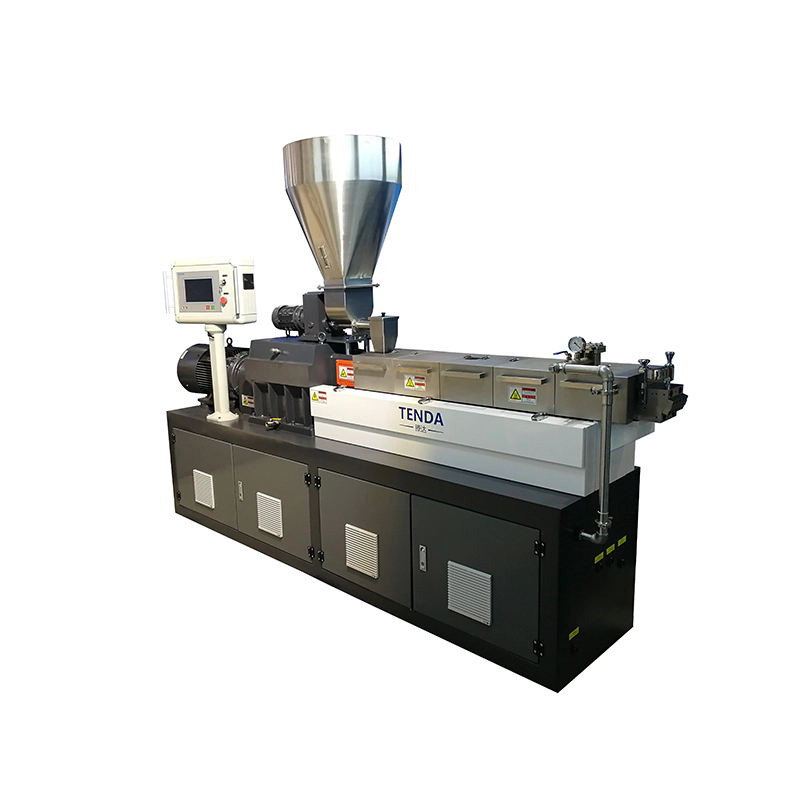

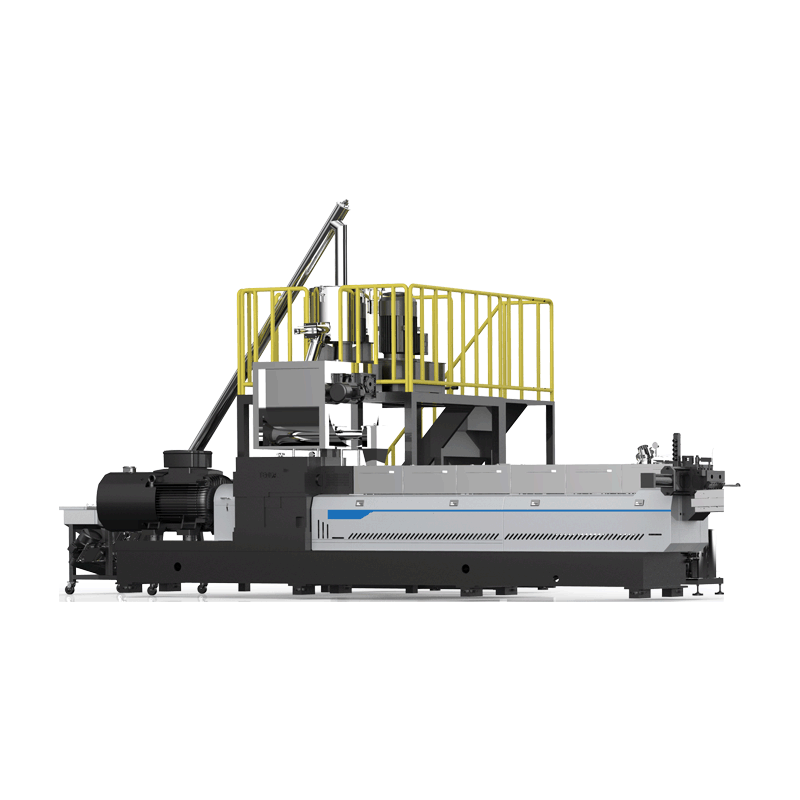

Extruder recycling, also known as regrind recycling, has emerged as a sustainable solution to reduce plastic waste in injection molding. The process involves collecting runner waste and other scrap plastic from the injection molding process, grinding it into small particles, and using it again in the production cycle. Through extruder recycling, these plastic scraps can be given a new lease of life, minimizing the need for virgin plastic material and reducing the amount of waste sent to landfills or incinerated.

The Benefits of Using Recycled Plastic in Injection Molding

1. Environmental Impact Reduction

One of the most significant advantages of utilizing recycled plastic in injection molding is the substantial reduction in environmental impact. Plastic waste is a major contributor to pollution, emitting greenhouse gases and leaching toxins into the soil and water. By recycling plastic waste through extruder recycling, we can alleviate these adverse effects. It reduces the need for new plastic production, conserves natural resources, and mitigates pollution associated with plastic manufacturing and disposal.

Moreover, extruder recycling enables us to tap into the vast amounts of plastic waste that have already been generated. By reusing this discarded plastic, we can effectively close the loop and prevent it from ending up in ecosystems where it can harm wildlife and degrade our environment. Embracing recycled plastic in the injection molding process is a significant step towards a more circular economy and a sustainable future.

2. Energy and Cost Savings

Another considerable advantage of utilizing recycled plastic in injection molding is the substantial energy and cost savings. The production of virgin plastic requires significant amounts of energy, primarily derived from fossil fuels. On the contrary, the recycling process consumes considerably less energy. By using recycled plastic, we reduce our reliance on fossil fuels and decrease greenhouse gas emissions associated with plastic manufacturing.

In addition to energy savings, using recycled plastic can also result in cost savings for manufacturers. Recycled plastic is typically less expensive than virgin plastic. By incorporating recycled materials into the injection molding process, manufacturers can reduce material costs without compromising product quality. These cost savings can be substantial, especially for high-volume production runs, making recycled plastic an economically viable alternative for injection molding.

3. Improved Environmental Image

In today's world, environmental consciousness plays an increasingly vital role in shaping public opinion about companies and their products. By embracing the use of recycled plastic in injection molding, businesses can enhance their environmental image and appeal to eco-conscious consumers. Demonstrating a commitment to sustainability and responsible waste management can strengthen brand reputation and attract a growing segment of environmentally aware customers.

Consumers are becoming more discerning, seeking products that align with their values and contribute to a greener future. Incorporating recycled plastic into injection molding not only demonstrates environmental responsibility but also allows manufacturers to tap into the growing market for sustainable products. By leveraging recycled materials, businesses can differentiate themselves and gain a competitive edge in today's eco-conscious marketplace.

4. Maintaining Material Performance

A common concern when transitioning from virgin plastic to recycled plastic in injection molding is potential degradation in material performance. However, advancements in recycling technologies have significantly reduced this issue. Recycled plastic can now meet the same stringent performance requirements as its virgin counterparts, making it a viable option for a wide range of applications.

Through careful sorting, cleaning, and processing, recycled plastic can be transformed into consistent, high-quality material suitable for injection molding. Mechanical properties such as strength, durability, and flexibility can be retained, ensuring that the final products meet the necessary specifications. By leveraging the benefits of extruder recycling, manufacturers can embrace sustainability without compromising on product quality.

5. Regulatory Compliance

Governments and regulatory bodies worldwide are increasingly implementing measures to curb plastic pollution and promote recycling initiatives. By incorporating recycled plastic in injection molding, manufacturers can ensure compliance with these regulations and avoid potential penalties or legal issues. Using recycled materials demonstrates a commitment to environmental stewardship and aligns with the circular economy principles that many nations are striving to achieve.

Furthermore, many countries are introducing extended producer responsibility (EPR) programs that make manufacturers accountable for the waste resulting from their products. By embracing extruder recycling and incorporating recycled plastic, manufacturers can fulfill their EPR obligations and contribute to a more sustainable waste management system.

Conclusion

Extruder recycling offers numerous benefits for injection molding, paving the way for a more sustainable and environmentally responsible manufacturing process. By utilizing recycled plastic, we can actively reduce the environmental impact, conserve resources, and mitigate plastic pollution. The advantages include not only decreased energy consumption and cost savings but also an improved environmental image for businesses and the ability to meet regulatory requirements.

As consumers increasingly demand sustainable products, incorporating recycled plastic in injection molding is a win-win situation. Manufacturers can reduce their environmental footprint, offer cost-effective solutions, and appeal to a growing market segment. This shift towards recycling and sustainable practices in injection molding is essential for the longevity of our planet and the well-being of future generations. By embracing extruder recycling, we take a significant step towards a greener, cleaner, and more sustainable future.

As we have known for quite some time, the success of TENGDA in the future will depend greatly on our ability to strike a balance between valuable human insight and interaction with technology.

Click TENGDA Extruder Machine Manufacturers for super quality from one of the state's premier producers.

Loyalty programs provide an opportunity to learn the preferences of customers and design communication strategies that will resonate with Application.

have three basic components.