Extruding Recycled Plastic: A Cost-Effective Solution for Manufacturers

Advantages of Extruding Recycled Plastic: A Cost-Effective Solution for Manufacturers

In today's world, sustainability has become a crucial consideration for businesses across various industries. As the detrimental effects of climate change continue to be felt globally, it is imperative for companies to adopt eco-friendly practices. One area where manufacturers can make a significant impact is in their use of materials. Plastic, in particular, has long been a source of concern due to its negative environmental impact. However, by embracing extruded recycled plastic, manufacturers can not only address sustainability concerns but also benefit from cost savings and a host of other advantages.

Understanding Extruded Recycled Plastic

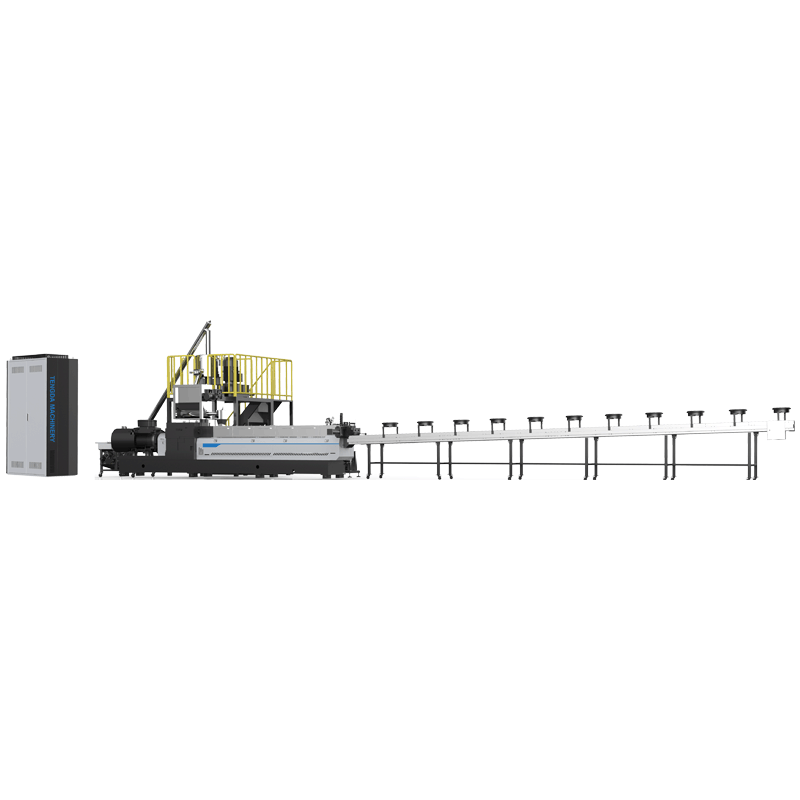

Extruded recycled plastic is a process by which used plastic waste is transformed into new products. The process involves collecting plastic waste, cleaning and sorting it, melting it down, and then extruding it to create new plastic materials, such as pellets, sheets, or profiles. These recycled materials can be used in a wide variety of applications, from packaging to construction, automotive parts to furniture.

The process of extruding recycled plastic offers several advantages over using virgin plastic materials. This article will explore some of these benefits, highlighting why it is a cost-effective solution for manufacturers.

Reduced Costs in Raw Material Acquisition

One of the primary advantages of using extruded recycled plastic is the reduced cost of raw materials. Virgin plastic, made from petroleum or natural gas, can be expensive and subject to fluctuations in price due to market forces. On the other hand, recycled plastic is often more affordable and provides manufacturers with a stable supply chain. By using recycled plastic, manufacturers can achieve substantial cost savings in their production processes, boosting their bottom line.

Furthermore, the cost of producing recycled plastic is typically lower than that of creating virgin plastic. The energy required to recycle plastic is considerably less than what is needed for the production of virgin plastic. This reduced energy consumption results in lower manufacturing costs, making extruded recycled plastic an economically viable choice for manufacturers.

Environmental Benefits of Extruded Recycled Plastic

The environmental advantages of using extruded recycled plastic are numerous. Firstly, recycling plastic waste significantly reduces the amount of plastic ending up in landfills. Plastics take hundreds of years to decompose, and their disposal leads to environmental pollution and the depletion of finite resources. By recycling plastic, manufacturers contribute to a circular economy, where materials are reused and waste is minimized.

Additionally, the production of recycled plastic emits fewer greenhouse gases compared to the production of virgin plastic. The process of extracting, refining, and manufacturing virgin plastic involves substantial energy consumption, primarily derived from fossil fuels. In contrast, recycling plastic requires less energy and reduces reliance on fossil fuels, thereby lowering carbon emissions and mitigating climate change.

Moreover, the use of recycled plastic helps to conserve natural resources. By utilizing plastic waste as a raw material, manufacturers reduce the demand for fresh petroleum or natural gas extraction. This preservation of resources ensures their availability for future generations while reducing the environmental impact of extraction activities.

Quality and Performance of Extruded Recycled Plastic

Some manufacturers express concerns regarding the quality and performance of recycled plastic compared to its virgin counterpart. However, advancements in recycling technologies have led to recycled plastic materials that can match or even surpass the quality of virgin plastic.

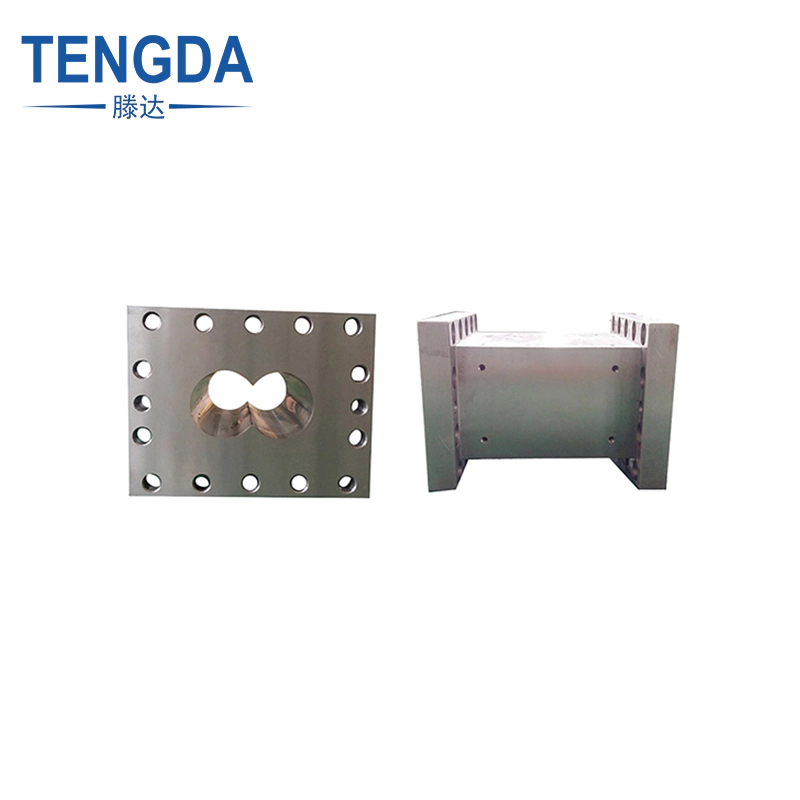

Extruded recycled plastic undergoes rigorous cleaning processes, ensuring that impurities such as dirt or contaminants are removed. This meticulous cleaning guarantees the production of high-quality recycled plastic materials. By investing in advanced recycling technologies, manufacturers can achieve recycled plastic with properties comparable to virgin plastic in terms of strength, durability, and stability.

To further enhance the performance of extruded recycled plastic, additives can be incorporated during the extrusion process. These additives can improve characteristics such as UV resistance, fire retardancy, or color vibrancy, expanding the range of applications for recycled plastic products.

Regulatory Compliance and Market Demand for Sustainable Solutions

Another compelling reason for manufacturers to embrace extruded recycled plastic is regulatory compliance and market demand. Governments and regulatory bodies worldwide are implementing stricter environmental regulations and standards for businesses, compelling manufacturers to adopt sustainable practices. By demonstrating a commitment to sustainability through the use of recycled plastic, businesses can ensure compliance with these regulations and avoid potential penalties or reputational damage.

Moreover, consumer demand for eco-friendly products continues to rise. More and more customers are actively seeking out environmentally responsible options. By using extruded recycled plastic in their products, manufacturers can tap into this growing market of environmentally conscious consumers, enhancing their brand image and gaining a competitive edge.

The Future of Extruded Recycled Plastic

The adoption of extruded recycled plastic is a win-win for manufacturers. It not only addresses concerns about sustainability and the environment but also offers significant cost savings and competitive advantages. As recycling technologies continue to evolve and improve, the quality of recycled plastic will further enhance, making it an even more attractive alternative to virgin plastic.

In conclusion, extruding recycled plastic is a cost-effective solution that allows manufacturers to contribute positively to the environment while maintaining their bottom line. The reduced costs in raw material acquisition, environmental benefits, and the market demand for sustainable solutions make extruded recycled plastic an appealing choice for forward-thinking manufacturers. By embracing this innovative approach, businesses can pave the way for a greener and more sustainable future.

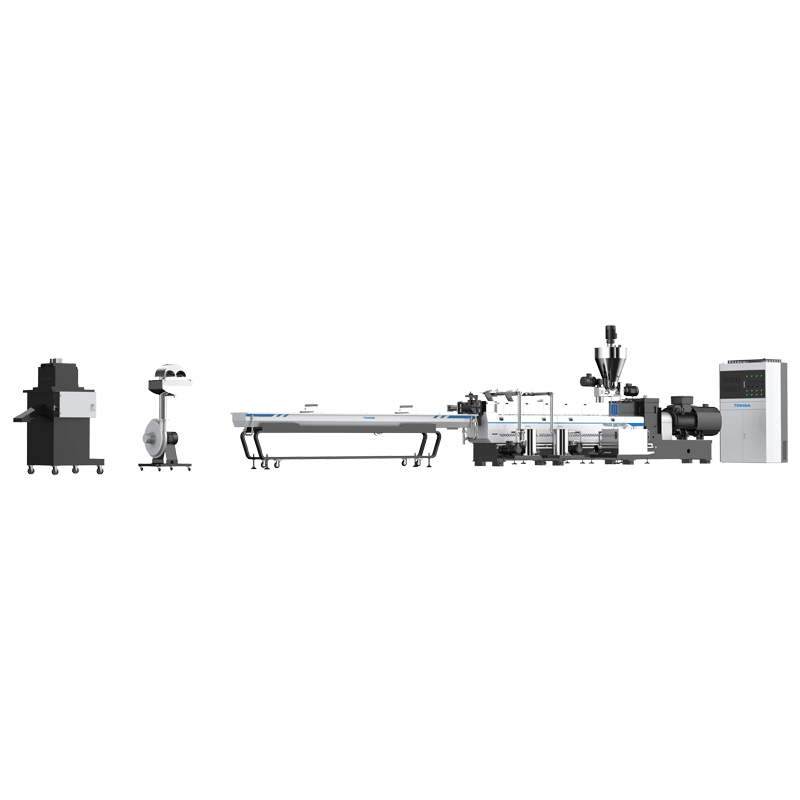

Nanjing Tengda Machinery Co., Ltd.’s administrative systems and management team are extraordinary-you'll need them to get a new location up and running.

Nanjing Tengda Machinery Co., Ltd. offers the best products, high-quality services and innovative technology.

Among improvements to Application, nearly half of consumers considered quality and service as the most important change a business could make in its supply chain.

Nanjing Tengda Machinery Co., Ltd. knows how important it is to offer optional extras, such as Applicationextruder machine manufacturers to provide quality products for customers.