Extruding Recycled Plastic: Reducing Waste and Costs in the Manufacturing Process

Plastic waste has become a growing concern in today's world, with its adverse effects on the environment and human health. To tackle this issue, many industries are turning to recycling as a way to reduce waste and lower costs. One such solution is the process of extruding recycled plastic, which offers significant benefits for manufacturers. By transforming waste materials into valuable resources, extruding recycled plastic not only reduces waste but also helps in creating a more sustainable manufacturing process. In this article, we will explore the various aspects of extruding recycled plastic and how it can contribute to waste reduction and cost savings.

The Basics of Extruding Recycled Plastic

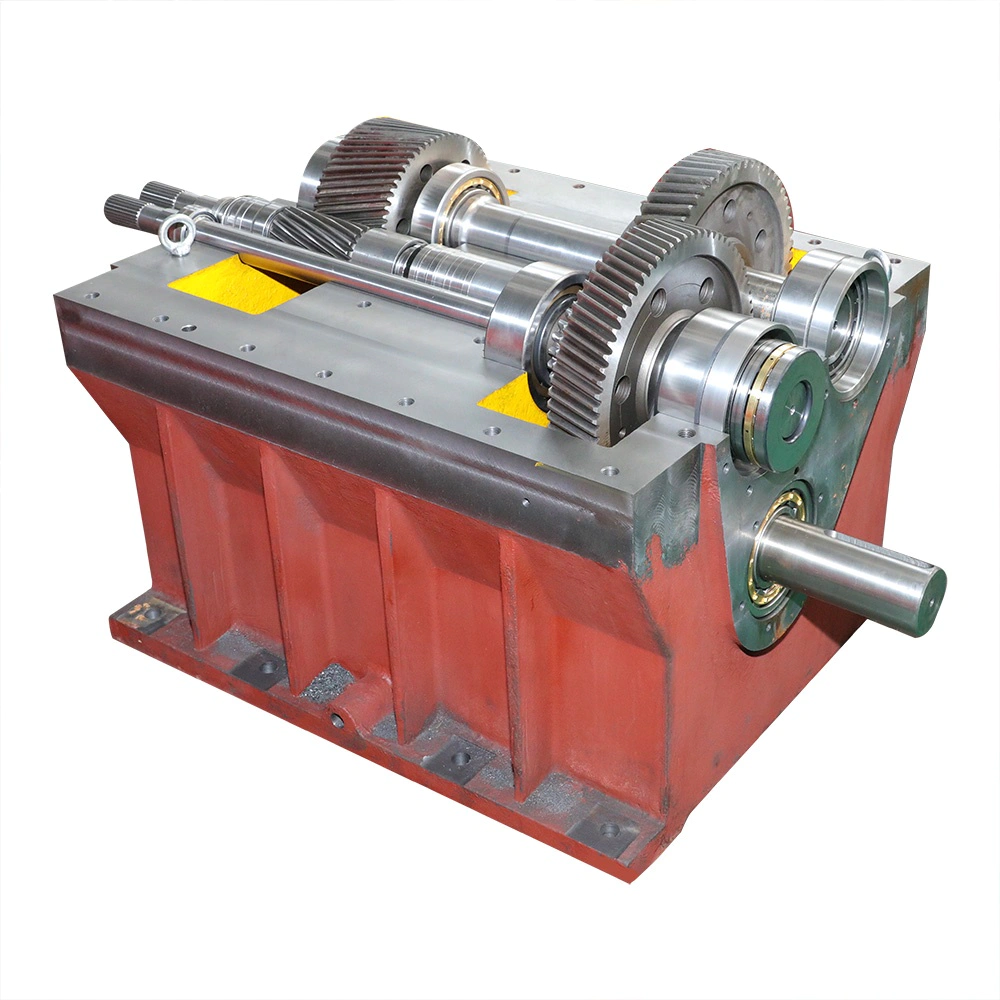

Extrusion is a widely used manufacturing process that involves melting raw plastic materials and shaping them into a continuous profile through a die. When it comes to extruding recycled plastic, the starting point is the collection of plastic waste. This waste can include discarded plastic products, packaging materials, or even post-industrial scrap. Once collected, the waste plastic is sorted, cleaned, and processed to remove any impurities such as dirt, labels, or non-plastic materials.

The cleaned and sorted plastic waste is then shredded into small pieces and fed into an extrusion machine. In the extruder, the plastic chips are heated to their melting point and forced through a die, which determines the shape of the final product. The molten plastic is then cooled and solidified into the desired form, such as rods, pellets, sheets, or profiles. These recycled plastic products can be used in a wide range of applications, from construction materials to packaging solutions.

The Benefits of Extruding Recycled Plastic

The process of extruding recycled plastic offers numerous benefits for both manufacturers and the environment. Let's take a closer look at some of these advantages:

1. Waste Reduction: One of the most significant benefits of extruding recycled plastic is the reduction in waste. By utilizing plastic waste as a raw material, manufacturers can divert tons of plastic from landfills and incineration facilities. This not only helps to conserve valuable landfill space but also reduces the environmental impact associated with the disposal of plastic waste. Recycling plastic through extrusion contributes to a circular economy, where materials are reused instead of being discarded.

2. Cost Savings: Incorporating recycled plastic into the manufacturing process can lead to significant cost savings for businesses. Compared to virgin plastic, which is derived from fossil fuels, recycled plastic is often more cost-effective as it eliminates the need for extracting and refining new raw materials. Additionally, recycling plastic consumes less energy than producing new plastic, resulting in lower energy costs. By utilizing extruded recycled plastic, manufacturers can reduce their overall production costs while promoting a more sustainable business model.

3. Environmental Impact: The environmental benefits of extruding recycled plastic are substantial. Manufacturing plastic from virgin materials requires the extraction of fossil fuels, which contribute to greenhouse gas emissions and environmental degradation. Recycling plastic not only conserves resources but also reduces energy consumption and greenhouse gas emissions. By choosing to incorporate extruded recycled plastic in their products, manufacturers can significantly reduce their carbon footprint and contribute to a greener future.

4. Product Diversity: The versatility of extruding recycled plastic allows manufacturers to create a wide range of products with varying shapes and sizes. By utilizing different types of plastic waste, such as PET bottles or HDPE containers, manufacturers can produce a diverse range of recycled plastic products. This flexibility opens up new opportunities for innovative designs and applications, enabling manufacturers to cater to different industries and consumer demands.

5. Market Demand: With growing awareness about environmental sustainability, there is an increasing demand for products made from recycled materials. Consumers are actively seeking eco-friendly alternatives and are willing to support businesses that prioritize sustainability. By incorporating extruded recycled plastic into their products, manufacturers can tap into this expanding market and attract environmentally conscious consumers. This not only helps in boosting sales but also enhances the brand image and reputation of the business.

The Future of Extruding Recycled Plastic

As plastic waste continues to be a global challenge, the process of extruding recycled plastic holds immense potential for the future. The demand for recycled plastic products is expected to rise as businesses and consumers increasingly prioritize sustainability. To maximize the benefits of extrusion, further advancements in recycling technologies and processes are crucial. Improving sorting and cleaning techniques, increasing the efficiency of extruders, and exploring new ways to incorporate recycled plastic in various industries are some areas that require continued research and development.

In conclusion, extruding recycled plastic offers an effective solution to reduce waste and costs in the manufacturing process. By utilizing waste plastic as a valuable resource, manufacturers can contribute to a more sustainable and circular economy. The benefits of waste reduction, cost savings, environmental impact, product diversity, and market demand make extruded recycled plastic an attractive choice for businesses. As we look towards a more sustainable future, the process of extruding recycled plastic will play a significant role in building a greener and more responsible manufacturing industry.

The use of plastic extruder machine manufacturers Application is a great trend in today's world. What you should know is that it has become a very important part of business today.

Click TENGDA Extruder Machine Manufacturers for super quality from one of the state's premier producers.

In conjunction with retraining and upskilling efforts, Nanjing Tengda Machinery Co., Ltd.’s workers should focus on growing unique human skills that high-tech machines are unable to replicate, such as strategic and abstract thinking, complex communications, creativity and leadership competencies.

Nanjing Tengda Machinery Co., Ltd. might focus its marketing efforts by highlighting its end product—improved technology and increased profits—not its producing methods.

give you an additional extruder machine manufacturers option for your plastic extruder machine manufacturers, whether it being a extruder machine manufacturers, plastic extruder machine manufacturers or extruder machine manufacturers. Go and get more info at TENGDA Extruder Machine Manufacturers.