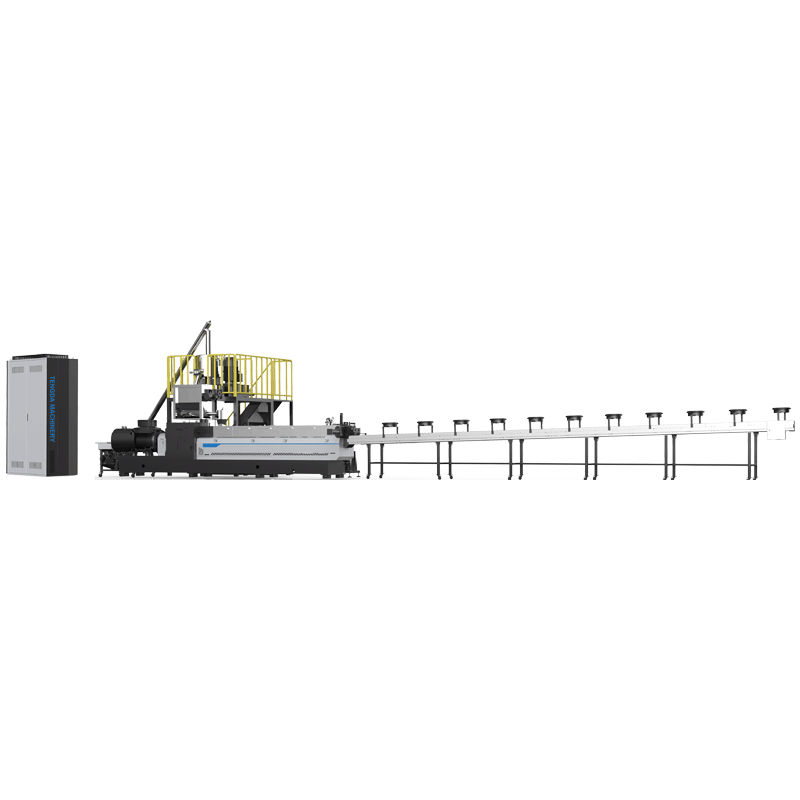

Extrusion Pelletizing Machine: How It Can Benefit Your Business

Are you looking for a solution to efficiently process plastic waste? Are you searching for a way to streamline your production processes and enhance the quality of your products? If so, then an extrusion pelletizing machine might be the answer you’ve been looking for. This advanced piece of equipment has revolutionized the plastic industry, allowing businesses to optimize their operations and reap numerous benefits. In this article, we will explore the various advantages that an extrusion pelletizing machine can bring to your business, ensuring a more sustainable and profitable future.

Increased Efficiency and Productivity

One of the primary benefits of using an extrusion pelletizing machine is the significant increase in efficiency and productivity it offers. This machine automates the entire plastic pelletizing process, reducing the need for manual labor and minimizing human error. By eliminating manual handling, the machinery operates seamlessly, resulting in a streamlined production line that can run continuously without interruptions.

With its ability to process a large volume of plastic materials, an extrusion pelletizing machine can also handle different types of plastic simultaneously. This versatility allows businesses to recycle various plastic waste and process them into high-quality pellets. Whether your business deals with polyethylene, polypropylene, polystyrene, or other plastic materials, this machine can efficiently convert them into valuable pellets.

Moreover, an extrusion pelletizing machine can enhance the quality and consistency of the plastic pellets produced. It ensures that the pellets have a uniform shape, size, and density, which are crucial factors in achieving excellent product performance. By maintaining consistent pellet quality, businesses can satisfy customer demands and increase customer satisfaction, ultimately leading to better business growth and profitability.

Eco-Friendly Solution

In today's eco-conscious world, sustainability has become a key concern for businesses. With an extrusion pelletizing machine, your business can actively contribute to a greener future by efficiently recycling plastic waste. By transforming the waste into reusable pellets, you not only reduce the amount of plastic being sent to landfills but also decrease the need for virgin plastic production.

The process of pelletizing plastic waste using an extrusion machine is environmentally friendly in multiple ways. Firstly, it helps conserve resources by reusing plastic materials instead of relying solely on new raw materials. Secondly, it reduces the energy consumption and carbon footprint associated with the production of plastic from scratch. By adopting an extrusion pelletizing machine, your business demonstrates a commitment to sustainability, attracting environmentally conscious customers and enhancing your corporate image.

Cost Savings

Implementing an extrusion pelletizing machine in your business can also lead to significant cost savings in the long run. Firstly, by recycling plastic waste, you reduce the costs associated with purchasing new raw materials for plastic production. This allows you to lower production costs and enhance your profit margins. Additionally, recycling plastic waste also reduces the expenses involved in waste disposal, as less waste is sent to landfills or incinerators.

Furthermore, an extrusion pelletizing machine operates efficiently and effectively, optimizing the production process. This means that your business can produce a higher volume of high-quality pellets in a shorter period, resulting in increased productivity. With less time spent on production, your business can save on labor costs and allocate resources to other areas of the operation. Moreover, the automated process significantly reduces the chances of human error, minimizing the need for rework and enhancing overall operational efficiency.

Versatility and Adaptability

The versatility and adaptability of an extrusion pelletizing machine make it a valuable asset for businesses operating in diverse industries. Whether you are in the packaging industry, construction, automotive, or any other sector utilizing plastic materials, this machine can cater to your specific needs.

Extrusion pelletizing machines are designed to handle a wide range of plastic materials, including rigid and flexible plastics, films, sheets, and even fiber-reinforced plastics. This flexibility allows businesses to explore different opportunities and expand their product range. Whether you want to produce plastic pellets for injection molding, film extrusion, or any other application, this machine can handle it all.

Additionally, extrusion pelletizing machines can be customized and tailored to meet your specific requirements. From the size and output capacity to the control systems and automation integration, these machines can be adjusted to fit seamlessly into your existing production line. This adaptability ensures a smooth transition and minimizes disruption during the implementation process.

Enhanced Product Quality

Product quality is of utmost importance for every business. By using an extrusion pelletizing machine, you can enhance the quality of your plastic pellets, thus improving the overall quality of your end products. The machine ensures that the pellets produced have uniform properties, such as size, shape, and melt flow index, which are critical factors in achieving consistent product performance.

The uniformity achieved by the extrusion pelletizing machine translates into more reliable and predictable production processes. It reduces the likelihood of defects and inconsistencies in the final products, eliminating the need for rejections or rework. Consistent product quality not only enhances customer satisfaction but also reduces costs associated with customer complaints and returns.

Moreover, the high-quality pellets produced by the extrusion pelletizing machine can also lead to improved product characteristics. The pellets exhibit excellent flow properties, which are crucial for injection molding processes, ensuring flawless mold filling and minimizing defects in the final products. The enhanced properties of the pellets contribute to better end product performance, durability, and aesthetics.

Conclusion

In conclusion, an extrusion pelletizing machine offers numerous benefits that can positively impact your business operations. From increased efficiency and productivity to cost savings and enhanced product quality, this machine revolutionizes the plastic industry. Additionally, by recycling plastic waste and contributing to a greener future, businesses can also improve their environmental footprint and enhance their corporate image.

Investing in an extrusion pelletizing machine is not only a smart business move but also a step towards promoting sustainable practices. With the versatility, adaptability, and high-quality output this machine offers, your business can unlock its full potential and strive for long-term success. So, why wait? Upgrade your operations with an extrusion pelletizing machine and embark on a journey towards a more sustainable and profitable future.