Extrusion Pelletizing Machine: Maximizing Your Output and Reducing Waste

Maximizing Your Output and Reducing Waste

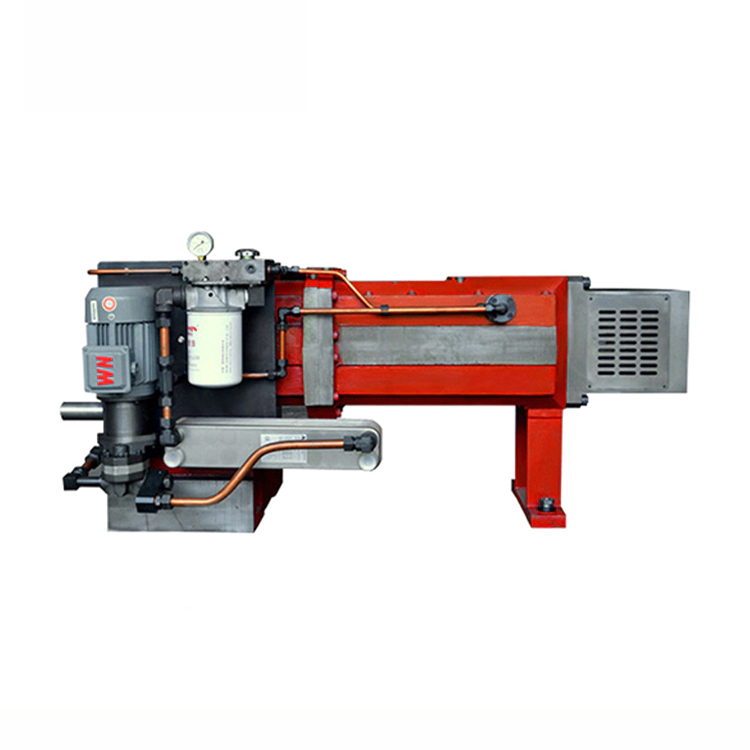

Are you tired of low productivity and wasted resources in your manufacturing process? Look no further than the extrusion pelletizing machine. With its efficient design and advanced technology, this machine is revolutionizing the industry by maximizing output and reducing waste. In this article, we will explore the features and benefits of this remarkable equipment, as well as its impact on various industries. So, let's dive in and discover how an extrusion pelletizing machine can transform your production line.

The Basics of Extrusion Pelletizing

Before delving into the details, let's first understand what extrusion pelletizing is all about. Extrusion pelletizing is a process that involves transforming raw materials into small, uniform pellets or granules. These pellets are easier to handle, transport, and store, making them ideal for a wide range of industries, including plastics, chemicals, pharmaceuticals, food, and more.

By feeding materials into an extruder, which contains a rotating screw, the raw materials undergo heat, pressure, and shearing forces. As the materials pass through the extruder, they get melted, mixed, and homogenized. Once the desired consistency is achieved, the molten material is forced through a die plate, shaping it into pellets. These pellets are then cooled, solidified, and cut into the desired length.

Now that we have a basic understanding of the process, let's explore the various ways an extrusion pelletizing machine can maximize your output and reduce waste.

Improved Efficiency and Productivity

One of the main advantages of using an extrusion pelletizing machine is its ability to significantly improve efficiency and productivity. With its streamlined design and precise control system, this machine ensures a consistent and continuous production flow. The automated process eliminates the need for manual intervention, reducing the chances of human error and increasing overall productivity.

Furthermore, the extrusion pelletizing machine can handle a wide range of materials, including polymers, additives, fillers, and colorants. This versatility allows manufacturers to process multiple materials simultaneously or switch between different materials with ease. By optimizing the production process, manufacturers can achieve higher throughput and faster cycle times, ultimately maximizing their output.

Reduced Waste and Resource Optimization

In addition to improved productivity, an extrusion pelletizing machine is designed to minimize waste and optimize the use of resources. The machine's precise temperature control and screw configuration enable efficient melting and mixing of materials, ensuring homogeneity and reducing material loss. Moreover, the die plate and cutting mechanism produce uniform pellets with minimal size variations, further minimizing waste.

Furthermore, the extrusion pelletizing process eliminates the need for additional steps such as drying or blending, which are commonly required in alternative processing methods. This reduction in process steps not only saves time but also minimizes the use of auxiliary equipment, energy, and resources, leading to significant cost savings.

Flexibility and Customization

Every manufacturing process has its unique requirements, and the extrusion pelletizing machine understands this. It offers a high degree of flexibility and customization options to meet the specific needs of different industries. Manufacturers can choose from a variety of extruder sizes, screw configurations, die plates, and pellet cutting mechanisms to tailor the machine's performance according to their production requirements.

Whether you need small or large-sized pellets, different shapes, or specific additives incorporated into the pellets, the extrusion pelletizing machine can be adjusted accordingly. This versatility allows manufacturers to create a wide range of end products, expanding their market opportunities and catering to diverse customer demands.

Enhanced Product Quality

A key factor in any manufacturing process is the quality of the end product, and an extrusion pelletizing machine excels in delivering high-quality pellets. The controlled and uniform melting, mixing, and shaping process ensures consistent material properties throughout the production run. This consistency translates into pellets with uniform size, shape, and chemical composition, meeting the desired specifications.

Moreover, the reduced exposure to air and moisture during the extrusion process minimizes the risk of degradation or contamination, ensuring the integrity of the final product. The optimized cooling system and precise cutting mechanism further contribute to the overall product quality. By producing high-quality pellets, manufacturers can enhance their reputation, increase customer satisfaction, and gain a competitive edge in their respective industries.

Applications Across Industries

The benefits of an extrusion pelletizing machine are not limited to a specific industry; they extend across various sectors. Let's explore some of the industries that can leverage this technology to maximize their output and reduce waste.

1. Plastics Industry: The plastics industry is one of the primary users of extrusion pelletizing machines. From producing plastic films and sheets to manufacturing plastic products, an extrusion pelletizing machine offers improved efficiency, reduced waste, and enhanced product quality. It also enables manufacturers to incorporate additives and colorants into the pellets, adding value and versatility to their products.

2. Chemical Industry: In the chemical industry, extrusion pelletizing machines are used to process different types of chemicals, such as pigments, catalysts, detergents, and more. The controlled and consistent production ensures the desired chemical composition, enabling manufacturers to deliver high-quality products to their customers.

3. Pharmaceutical Industry: The pharmaceutical industry benefits from extrusion pelletizing machines in the production of drug formulations, controlled-release systems, and oral solid dosage forms. The precise control over temperature, mixing, and particle size distribution ensures the efficacy, uniformity, and stability of medications, adhering to strict regulatory requirements.

4. Food Industry: In the food industry, extrusion pelletizing machines are utilized for the production of snacks, cereals, pet foods, and granular food ingredients. The ability to incorporate various ingredients, alter shapes, and create unique textures makes these machines indispensable for food manufacturers, enabling them to meet consumer preferences and market demands.

5. Recycling Industry: Recycling plastic waste is a significant challenge, and extrusion pelletizing machines play a vital role in addressing this issue. By transforming plastic waste into high-quality pellets, these machines facilitate the recycling process, reducing environmental impact and promoting sustainability.

Summary

The extrusion pelletizing machine is a game-changer for manufacturers across various industries. Its ability to maximize output and reduce waste through improved efficiency, reduced resource consumption, flexibility, and enhanced product quality makes it an indispensable asset. With evolving technologies and advancements in the field, the extrusion pelletizing machine continues to revolutionize manufacturing processes, opening doors for innovation, cost savings, and sustainable practices. Embrace this transformative technology and unlock the potential for success in your production line.