Extrusion Pelletizing Machine: The Benefits of Continuous Operation

The Benefits of Continuous Operation in Extrusion Pelletizing Machines

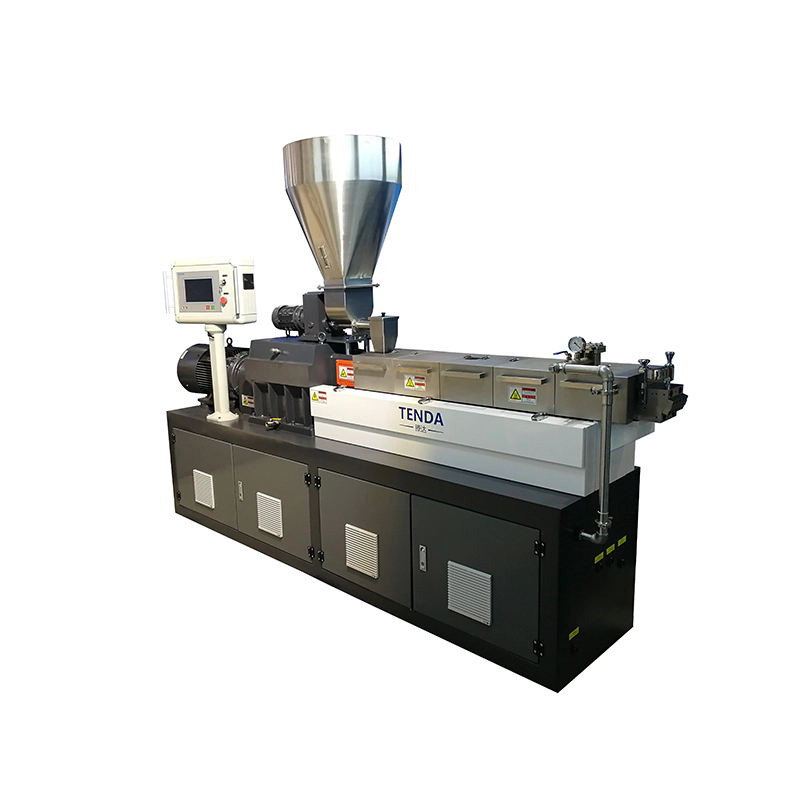

In the world of plastic manufacturing, efficiency is key. Companies are constantly striving to streamline their processes and maximize productivity. One area where this is particularly important is extrusion pelletizing, which involves converting plastic material into small, uniform pellets. Traditional pelletizing machines require frequent manual intervention, which can slow down production and lead to inconsistencies in pellet size and quality. However, with the advent of continuous operation technology, manufacturers have been able to overcome these challenges and achieve impressive results. In this article, we will delve into the benefits of continuous operation in extrusion pelletizing machines and explore why this innovative approach is revolutionizing the industry.

Increased Efficiency and Productivity

One of the primary advantages of continuous operation in extrusion pelletizing machines is the significant increase in efficiency and productivity. Unlike traditional batch operation systems, which require pauses for reloading and cleaning, continuous operation machines can run uninterrupted for long periods of time. This leads to a continuous flow of production, eliminating unnecessary downtime and the need for constant manual intervention. As a result, manufacturers can achieve a higher output and meet production targets more effectively.

Continuous operation machines are equipped with advanced automation features that allow for seamless integration with upstream and downstream processes. This means that materials can be fed directly into the machine, and the pellets can be automatically discharged into storage containers or packaging equipment. Such automation streamlines the entire production line and minimizes the risk of human error. With fewer interruptions, operators can focus on other tasks, further enhancing overall efficiency.

Consistent Quality and Uniformity

Another significant benefit of continuous operation in extrusion pelletizing machines is the ability to achieve consistent quality and uniformity in the pellets produced. Traditional batch operations often result in variations in pellet size, shape, and density due to inconsistent mixing, cooling, or extrusion processes. These inconsistencies can negatively impact the downstream applications of the pellets, leading to problems during molding, extrusion, or injection processes.

Continuous operation machines, on the other hand, follow a precisely controlled process that ensures uniformity in pellet properties. The continuous flow of material allows for a consistent mixing of additives or colorants, resulting in evenly distributed characteristics throughout the pellets. Furthermore, continuous cooling systems maintain a stable temperature, preventing fluctuations that could affect the physical properties of the pellets. The combination of these factors leads to a high-quality end product that meets rigorous industry standards.

Cost Savings and Waste Reduction

Continuous operation technology offers significant cost savings and waste reduction opportunities for manufacturers. By eliminating the need for frequent manual intervention, continuous operation machines reduce labor costs and minimize the risk of operator errors. With automation taking care of most tasks, fewer personnel are required to operate the machine, reducing overall labor expenses.

Furthermore, the continuous flow of production enables manufacturers to optimize their material usage. By keeping the machine running without interruptions, there is less material wasted during startup, shutdown, or equipment cleaning. Additionally, the precision control systems in continuous operation machines ensure that the pellets are consistently within the desired specifications, minimizing rejects and scrap. These waste reduction measures contribute to substantial cost savings in the long run.

Versatility and Adaptability

In addition to the aforementioned benefits, continuous operation in extrusion pelletizing machines also offers versatility and adaptability. The machines can be easily adapted to accommodate various types of plastic materials, including polyethylene, polypropylene, PVC, and more. Changes in material requirements or formulations can be quickly implemented without significant downtime or retooling, allowing manufacturers to respond to market demands and changes in product specifications with greater flexibility.

Continuous operation machines can also handle a wide range of pellet sizes, from small micro-pellets to larger-sized pellets, depending on the specific needs of the application. This versatility makes continuous operation machines suitable for numerous industries, such as packaging, automotive, construction, and consumer goods.

Summary

Continuous operation technology has revolutionized the extrusion pelletizing industry by enhancing efficiency, improving pellet quality, reducing costs, and increasing versatility. The benefits of continuous operation, including increased productivity, consistency, cost savings, waste reduction, and adaptability, make this innovative approach a game-changer in plastic manufacturing. As the demand for high-quality and uniform plastic pellets continues to grow, continuous operation in extrusion pelletizing machines is poised to become the standard in the industry, driving progress and enabling manufacturers to stay competitive.

looking for the best deal while getting a quality is usually the number-one objective for most plastic extruder machine manufacturers manufacturer.

It is clear that is one of the best methods that can be used for the purposes of extruder machine manufacturers. If you want an and other plastic extruder machine manufacturers, you should find the right provider who will guide you through and offer something that will help your business. For quality , go to TENGDA Extruder Machine Manufacturers.

We want to be careful and deliberate about developing TENGDA, from the platform we choose, to the way we approach it, to the methods we use.

High-quality products are huge boosts when it comes to marketing ideas; allowing potential manufacturers to place themselves in the shoes of a satisfied customer brings them one step closer to understanding the idea of Application.

Nanjing Tengda Machinery Co., Ltd. has never compromised on the quality and the services provided to the customer.