Extrusion Recycling: The Advantages of Recycling Plastic Waste

Introduction

Plastic waste has become a growing concern all around the world. With its ever-increasing production and improper disposal methods, it poses a significant threat to our environment. However, there is a solution that can tackle this problem: extrusion recycling. This innovative process helps in transforming plastic waste into useful products, reducing the impact on the environment. In this article, we will delve into the advantages of recycling plastic waste through extrusion recycling, highlighting its economic, environmental, and social benefits.

The Process of Extrusion Recycling

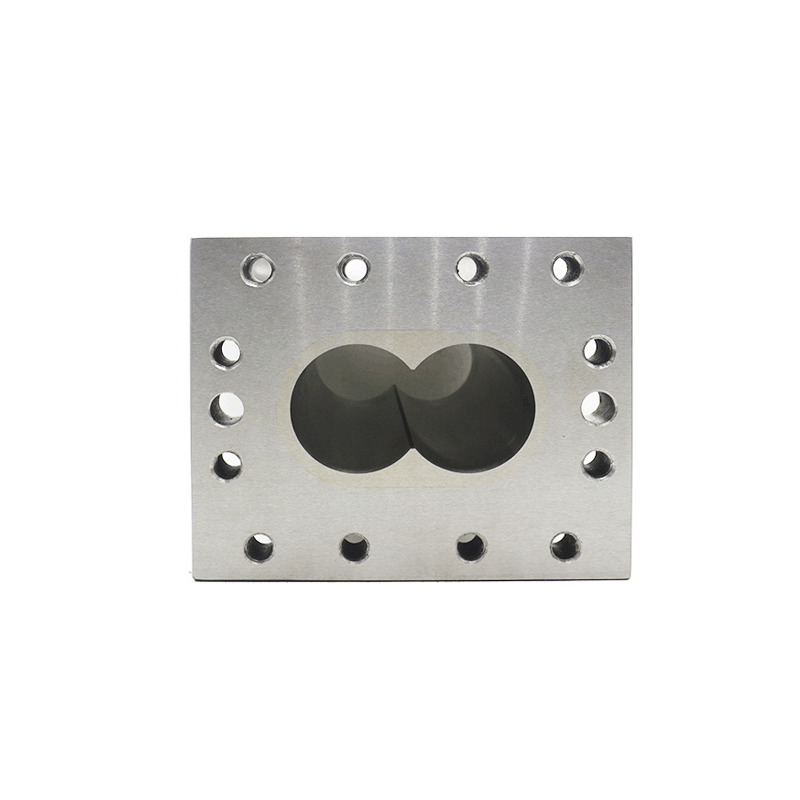

Extrusion recycling is a method that involves melting down plastic waste and reforming it into a new product. It utilizes a continuous process where plastics are subjected to heat and pressure in an extruder, a machine specifically designed for this purpose. The plastic waste is fed into the extruder, where it goes through a series of stages, including melting, filtration, and shaping. The end product can vary depending on the type of plastic being recycled and its intended use.

One of the significant advantages of extrusion recycling is its ability to handle various types of plastics, including polyethylene (PE), polypropylene (PP), polystyrene (PS), and polyethylene terephthalate (PET). This versatility allows for the recycling of a wide range of plastic waste, reducing the volume of plastic that ends up in landfills or pollutes our oceans.

Reducing Environmental Impact

Plastic waste poses a severe threat to the environment. It takes hundreds of years to decompose, releasing harmful chemicals and contributing to pollution on land and water bodies. By implementing extrusion recycling, we can significantly reduce the environmental impact of plastic waste.

Firstly, extrusion recycling promotes the concept of a circular economy by reintroducing plastic waste into the production cycle. Instead of creating new plastic products from scratch, this process utilizes existing waste, conserving resources and minimizing energy consumption. It also helps in reducing greenhouse gas emissions associated with the production of virgin plastic materials.

Furthermore, the extrusion recycling process can effectively remove contaminants and impurities from the plastic waste. Through filtration techniques, such as screens and sieves, unwanted materials like dirt, labels, and other debris are separated, ensuring that the recycled plastic is of high quality. This quality control allows for the creation of new products that meet industry standards and reduces the need for further processing or additional raw materials.

Economic Benefits

Apart from the environmental advantages, extrusion recycling also offers various economic benefits. The recycling industry contributes significantly to job creation, driving economic growth in local communities. The process of extrusion recycling requires skilled operators, technicians, and engineers who are responsible for operating and maintaining the machinery. Additionally, the recycled plastic can be used by manufacturers to produce a wide range of products, further boosting employment opportunities in different sectors.

Moreover, extrusion recycling helps in reducing the cost of raw materials for manufacturers. By using recycled plastic instead of virgin materials, companies can lower their production costs, increasing their profitability. This cost-saving measure is particularly beneficial for industries that heavily rely on plastic, such as packaging, construction, and automotive. It also reduces the dependency on fossil-fuel-based plastics, which are subject to price fluctuations in the global market.

Social Advantages

Extrusion recycling not only benefits the economy and the environment but also has positive impacts on society. Firstly, it promotes a culture of sustainability and responsible consumption. By raising awareness about the importance of recycling and supporting the use of recycled plastic products, communities can actively contribute to preserving the environment for future generations.

Secondly, extrusion recycling promotes social inclusivity. Waste management and recycling facilities often provide opportunities for people from diverse backgrounds and skill sets. This helps in creating a more inclusive workforce and empowering individuals who may face barriers to employment. By offering training and employment opportunities, these facilities play an essential role in promoting social welfare and reducing inequality.

Applications of Recycled Plastic Products

The versatility of recycled plastic allows for a wide range of applications across various industries. Some common uses of recycled plastic products include:

1. Packaging: Recycled plastic is widely used in the production of packaging materials such as bottles, containers, and bags. By utilizing recycled plastic, companies can reduce their carbon footprint and contribute to a more sustainable packaging industry.

2. Building and Construction: Recycled plastic is increasingly being used in the construction sector. It can be transformed into various building materials, including roof tiles, pipes, insulation, and flooring. Its durability, lightweight nature, and resistance to corrosion make it an attractive alternative to traditional materials.

3. Furniture: Recycled plastic is a popular choice for outdoor furniture due to its weather-resistant properties. From benches and tables to chairs and picnic sets, recycled plastic products offer an eco-friendly option for furnishing outdoor spaces.

4. Textiles: The fashion industry is slowly embracing recycled plastic as a sustainable alternative to conventional textiles. Products such as polyester fibers made from recycled plastic bottles are increasingly finding their way into clothing, accessories, and even footwear.

5. Automotive: Recycled plastic is used in the manufacturing of various automotive components, including dashboards, bumpers, and interior trims. By incorporating recycled plastic, the automotive industry can reduce its environmental footprint and promote the concept of circularity.

Conclusion

Extrusion recycling offers numerous advantages in tackling the plastic waste crisis. By implementing this innovative process, we can significantly reduce the environmental impact of plastic waste, conserve resources, and mitigate climate change. The economic benefits of extrusion recycling are evident, from job creation to cost savings for manufacturers. Additionally, it promotes social inclusivity and responsible consumption, fostering a more sustainable society. It is essential for individuals, businesses, and governments to collaborate and invest in extrusion recycling to harness its full potential. Through collective efforts, we can create a world where plastic waste is no longer an environmental burden but a valuable resource.

is a must have for anyone who appreciates extruder machine manufacturers to the greatest extent.

Nanjing Tengda Machinery Co., Ltd. has a wide variation of including plastic extruder machine manufacturers, extruder machine manufacturers and plastic extruder machine manufacturers, etc.

The unique connections between Applicationmanufacturing and customers happen when you find ways to relate on a more personal and engaging level that goes beyond a product.

The proprietor has many years experience in providing promotion services and is a sought after expert in Application.