Finding the Right Fit: Plastic Pelletizing Machines for Sale

Introduction

Plastic pelletizing machines have revolutionized the process of plastic recycling, enabling the conversion of waste plastics into useful and marketable products. The demand for these machines has skyrocketed in recent years, as businesses and industries worldwide strive to adopt more sustainable practices. With numerous plastic pelletizing machines for sale in the market, finding the right fit can be a challenging task for potential buyers. In this comprehensive article, we will delve into the world of plastic pelletizing machines, exploring their types, features, and key considerations to help you make an informed decision.

The Importance of Plastic Pelletizing Machines

The environmental impact of plastic waste has become a global concern, pushing industries and governments to find innovative solutions. Plastic pelletizing machines play a pivotal role in addressing this issue by offering an efficient and eco-friendly means of plastic waste management. These machines are designed to convert various forms of plastic waste, such as bottles, containers, and films, into small plastic pellets that can be reused in the production of new plastic products. This not only saves energy and reduces carbon emissions but also prevents plastic waste from ending up in landfills or the ocean, where it poses a severe threat to marine life.

The Types of Plastic Pelletizing Machines

Plastic pelletizing machines come in various types, each catering to specific types of plastic waste and production requirements. Understanding the different types can help you determine the most suitable machine for your needs.

1. Strand Pelletizing Machines

Strand pelletizing machines are widely used for processing thermoplastic materials, including polyethylene (PE), polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC). These machines feature a rotating rotor equipped with blades that cut extruded plastic strands into uniform pellets. The cutting action occurs in a water bath, which cools and solidifies the plastic strands before they are cut. Strand pelletizing machines are known for their versatility, high production capacity, and reliable performance.

When considering a strand pelletizing machine, it is essential to assess factors such as its throughput capacity, cutting speed, pellet uniformity, and compatibility with the type of plastic waste you intend to process. Additionally, pay attention to the machine's maintenance requirements and its ease of operation, as these factors can significantly impact your overall productivity and efficiency.

2. Underwater Pelletizing Machines

Underwater pelletizing machines offer a cutting-edge solution for processing temperature-sensitive and highly filled plastic materials. One of the significant advantages of underwater pelletizing is that it eliminates the need for a water bath to cool the plastic strands, as the cutting process takes place underwater. This enables the production of high-quality pellets with minimal thermal stress and excellent dimensional accuracy.

These machines are particularly beneficial for processing plastics with high melting points or those containing heat-sensitive additives. Examples include engineering plastics like acrylonitrile butadiene styrene (ABS), polyamide (PA), and polyethylene terephthalate (PET). Underwater pelletizing machines are known for their precision, automation capabilities, and ability to handle materials with varying viscosity.

When considering an underwater pelletizing machine, it is crucial to evaluate factors such as its cutting method, pellet quality control mechanisms, die plate design, and drying system. These features can influence the machine's ability to handle different types of plastic waste and ensure consistent pellet quality.

3. Air Cooling Pelletizing Machines

Air cooling pelletizing machines are ideal for processing thermoplastic materials that do not require water cooling, such as polypropylene (PP) and high-density polyethylene (HDPE). These machines utilize a rotating blade system to cut extruded plastic strands into pellets. Unlike strand and underwater pelletizing machines, air cooling pelletizing machines rely on ambient air for cooling, making them suitable for situations where water conservation is a priority.

When considering an air cooling pelletizing machine, it is essential to assess factors such as its cutting efficiency, pellet uniformity, ease of maintenance, and energy consumption. Additionally, consider the availability and cost of ambient air in your location, as this can impact the machine's overall operational costs.

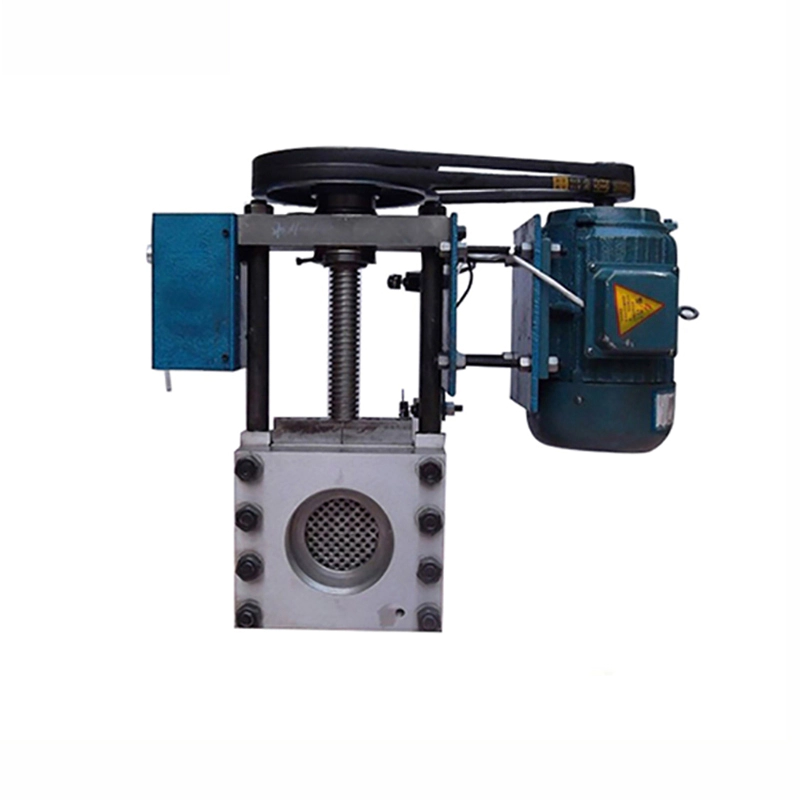

4. Die Face Pelletizing Machines

Die face pelletizing machines, also known as hot die face cutting machines, are commonly used for processing soft and low-melting-point plastic materials. These machines feature a heated die plate, which melts the plastic material and forces it through a cutting system to form pellets. The pellets are then cooled and collected for further processing.

Die face pelletizing machines offer advantages such as simplicity, compact design, and cost-effectiveness. They are well-suited for processing materials like low-density polyethylene (LDPE), ethylene vinyl acetate (EVA), and thermoplastic elastomers. However, it is important to note that die face pelletizing may not be suitable for every type of plastic waste, as some materials may require a different cutting method to achieve optimal results.

When considering a die face pelletizing machine, evaluate factors such as its melt capacity, pellet quality control mechanisms, die plate design, and compatibility with the plastic waste you intend to process. Additionally, consider the machine's energy consumption and maintenance requirements to ensure a smooth and efficient operation.

5. Disk Pelletizing Machines

Disk pelletizing machines are primarily used for the production of spherical pellets from a wide range of plastic materials, including PVC, polyolefins, and engineering plastics. These machines utilize a rotating disk to shape plastic granules or powder into uniform spherical pellets. The pellets are then cooled, solidified, and discharged for further processing.

Disk pelletizing machines offer advantages such as high pellet uniformity, precise control over pellet size, and the ability to handle a diverse range of plastic materials. They are widely used in industries such as automotive, agriculture, and construction, where the production of uniform and high-quality pellets is crucial.

When considering a disk pelletizing machine, it is important to assess factors such as the machine's pelletizing speed, pellet quality control mechanisms, disk design, and compatibility with the type of plastic waste you intend to process. Additionally, consider the machine's maintenance requirements, energy consumption, and its ability to handle different pellet sizes, as these factors can significantly impact your production efficiency.

Conclusion

Plastic pelletizing machines have emerged as a vital tool in the quest for sustainable plastic waste management. By converting plastic waste into pellets, these machines offer a sustainable and environmentally friendly solution, reducing the reliance on virgin plastic production. Understanding the different types of plastic pelletizing machines, such as strand, underwater, air cooling, die face, and disk pelletizing machines, is crucial in finding the right fit for your specific needs.

When selecting a plastic pelletizing machine, consider factors such as the type of plastic waste you will be processing, required pellet quality, production capacity, maintenance requirements, and operational costs. By carefully evaluating these factors and matching them with the capabilities of different machines, you can make an informed decision and find a plastic pelletizing machine that perfectly suits your requirements. Make sure to consult with reputable manufacturers or suppliers, ask for demonstrations or trials, and review customer feedback before making your final purchase. With the right plastic pelletizing machine, you can contribute to a more sustainable future while taking advantage of the economic opportunities presented by plastic waste recycling.

It is beyond doubt that benefits extruder machine manufacturers. Market sentiments are strong, especially in the light of growing plastic extruder machine manufacturers observed globally.

You will find a wide variety of for sale for virtually any extruder machine manufacturers needs. Keep in mind how you plan to use the , and talk with a professional about the model and features that are right for your application. Go to TENGDA Extruder Machine Manufacturers for on sale.

Using high technology, Application showed its competitive advantages, captioned with information about the company's commitment to providing safe, reliable, profitable jobs to local artisans.

Nanjing Tengda Machinery Co., Ltd. has developed a unique technology with many applications including plastic extruder machine manufacturers.