From Waste to Wealth: The Promise of Plastic Recycling Pelletizer Machines

Introduction: The Potential of Plastic Recycling Pelletizer Machines

Plastic waste has become a significant concern worldwide due to its detrimental impact on our environment. However, amidst this challenge lies an incredible opportunity to turn waste into wealth. Thanks to advancements in technology, plastic recycling pelletizer machines have emerged as a promising solution to address the ever-growing plastic waste problem. These machines are revolutionizing the recycling industry by transforming discarded plastic into high-quality plastic pellets that can be used in the production of various plastic products. In this article, we will explore the potential of plastic recycling pelletizer machines and delve into the myriad benefits they offer.

The Process of Plastic Recycling Pelletization

Plastic recycling pelletizer machines follow a comprehensive process that allows for effective recycling and pelletization of plastic waste. Firstly, the plastic waste is sorted and segregated based on its type and grade. This initial step is crucial to ensure that the recycling process remains efficient and the resulting plastic pellets are of high quality. Once sorted, the plastic waste is thoroughly cleaned and washed to eliminate any impurities or contaminants. This cleaning process helps in enhancing the purity and integrity of the final plastic pellets.

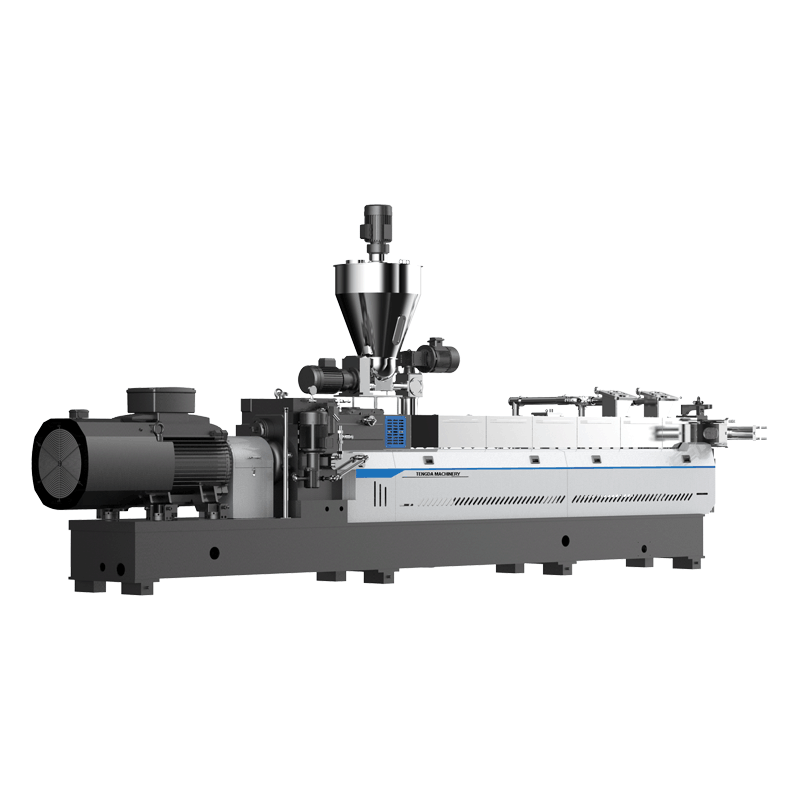

After the cleaning process, the plastic waste is fed into the recycling pelletizer machine, where it undergoes extrusion. Extrusion is a core process that involves melting the plastic waste and passing it through a die to form cylindrical strands. These strands are then cut into small pellets of uniform size. The resulting plastic pellets can be classified further based on their specific properties, such as color or composition. This classification enables the pellets to be used for a wide range of applications in the plastic industry.

The Advantages of Plastic Recycling Pelletizer Machines

Plastic recycling pelletizer machines offer a multitude of advantages that make them a crucial asset in the quest for sustainable waste management. Here are some notable benefits:

1. Reduced Environmental Impact:

One of the most significant advantages of plastic recycling pelletizer machines is their ability to minimize the environmental impact of plastic waste. By recycling plastic instead of sending it to landfills or incinerators, these machines help in conserving natural resources, reducing energy consumption, and decreasing greenhouse gas emissions associated with plastic production.2. Economic Opportunities:

Plastic recycling pelletizer machines create economic opportunities by turning waste into a valuable resource. The plastic pellets produced through these machines can be sold to manufacturers, who can then use them as a cost-effective alternative to virgin plastic. Additionally, the recycling industry generates employment opportunities, contributing to local economies.3. Resource Conservation:

Plastic recycling pelletizer machines play a vital role in conserving valuable resources. By recycling plastic waste, these machines eliminate the need for new raw materials, such as fossil fuels, which are required in the production of virgin plastic. This resource conservation helps in preserving finite resources and reducing the strain on the environment.4. Flexible and Versatile:

Plastic recycling pelletizer machines are designed to handle various types of plastic waste, including both rigid and flexible plastics. This versatility ensures that a wide range of plastic products can be recycled and transformed into useful plastic pellets. Furthermore, these machines can process plastics with varying compositions, allowing for effective recycling of mixed plastic waste.5. Quality Output:

Plastic recycling pelletizer machines produce high-quality plastic pellets that can be used in numerous applications. The pellets exhibit consistent properties and are free from impurities, ensuring excellent performance in the manufacturing of plastic products. Moreover, recycled plastic pellets often possess similar properties to virgin plastic, making them a reliable and eco-friendly alternative.Challenges Faced by Plastic Recycling Pelletizer Machines

While plastic recycling pelletizer machines offer immense potential, they also encounter certain challenges that need to be addressed for widespread adoption and success. Here are a few key challenges:

1. Contamination:

Despite thorough cleaning processes, plastic waste may still contain some contaminants that affect the quality of the recycled plastic pellets. Contamination can arise from various sources, such as residual food waste, labels, or adhesives. To overcome this challenge, improved sorting and cleaning techniques need to be implemented, along with consumer awareness campaigns to encourage proper disposal of plastic waste.2. Plastic Diversity:

The wide variety of plastic types and compositions poses a challenge to plastic recycling pelletizer machines. Each plastic type requires specific processing parameters, and mixed plastics can result in inferior quality pellets. Developing advanced technologies that can efficiently handle diverse plastic waste and produce high-quality pellets is crucial to overcome this challenge.3. Cost Considerations:

The initial investment required for plastic recycling pelletizer machines can be significant, making it a barrier for smaller businesses or communities. However, the long-term economic benefits, coupled with potential government incentives and grants, can help justify the cost and encourage more widespread adoption of these machines.4. Market Demand:

Creating a market demand for recycled plastic pellets is essential to ensure the viability of plastic recycling pelletizer machines. Educating manufacturers about the benefits of using recycled pellets and incentivizing the purchase of recycled materials can help establish a sustainable market for recycled plastics.Conclusion

Plastic recycling pelletizer machines hold immense promise in tackling the plastic waste crisis and transforming waste into wealth. With their ability to convert discarded plastic into high-quality plastic pellets, these machines contribute to a circular economy and a sustainable future. Despite the challenges faced, ongoing advancements and innovations in the recycling industry offer hope for overcoming these obstacles and maximizing the potential of plastic recycling pelletizer machines. By investing in these technologies and embracing a culture of responsible plastic waste management, we can pave the way for a greener, cleaner, and more prosperous future.

Looking for an innovative range of plastic extruder machine manufacturers Application products? Nanjing Tengda Machinery Co., Ltd. supplies a diverse range of consumer, commercial and specialty industrial products including Application, extruder machine manufacturers, plastic extruder machine manufacturers,etc.Click TENGDA Extruder Machine Manufacturers to learn more!

Providing highly qualified Application products and services, Nanjing Tengda Machinery Co., Ltd. is committed to helping clients make lasting improvements to their performance and realize their most important goals. Over the past decades, we’ve built a firm uniquely equipped to this task. Go to TENGDA Extruder Machine Manufacturers for more info.

Application is produced by Nanjing Tengda Machinery Co., Ltd.’s professional skills in high technology.

Nanjing Tengda Machinery Co., Ltd. are providing this to you at very low cost. Our claims are only based on different feed-backs received from various clients and not based on self-judgment.