How do you Pelletize plastic?

Why Pelletize Plastic?

Plastic is an indispensable material in our modern world. It is versatile, lightweight, and durable, making it suitable for a wide range of applications. However, the widespread use of plastic has also given rise to a significant environmental concern – plastic waste. Improper disposal and inefficient recycling of plastic can have detrimental effects on the environment, leading to pollution and damage to ecosystems.

To address this issue, various methods of plastic recycling have been developed. One of the most commonly used methods is pelletizing plastic. Pelletization offers numerous benefits, including easier storage, transportation, and handling of plastic waste. This article will delve into the process of plastic pelletization and explore its advantages and significance in waste management.

The Process of Pelletizing Plastic

Pelletizing plastic is the process of transforming plastic waste into small, uniform pellets. These pellets are easier to handle, store, and transport compared to bulky and irregularly shaped plastic waste. The process typically involves several stages, including sorting, shredding, washing, drying, and extrusion.

Sourcing and Sorting Plastic Waste

Sourcing and sorting plastic waste is the initial step in the pelletization process. Various sources of plastic waste, such as post-industrial waste, post-consumer waste, and plastic bottles, are collected and sorted based on their polymer type and quality. The sorting stage ensures that the plastic pellets produced are of consistent quality, which is crucial in applications that require specific material properties.

Sorting can be done manually or through automated systems that employ optical sensors, infrared technology, or other advanced methods to identify and separate different types of plastics. This stage is essential to avoid contaminating the final product with incompatible plastics, as different polymers often have distinct melting points and processability.

Shredding and Grinding the Plastic Waste

Shredding and grinding the plastic waste is the next step in the pelletization process. The sorted plastic waste is fed into a shredder or granulator, where it is broken down into smaller pieces or flakes. Shredding increases the surface area of the plastic waste, making it easier to wash and dry in subsequent stages.

The size of the shredded plastic particles may vary depending on the specific requirements of the pelletizing equipment used. Generally, smaller particle sizes are desirable as they facilitate uniform feeding during extrusion and result in pellets with consistent dimensions.

Washing and Drying the Shredded Plastic

Washing and drying the shredded plastic is a critical stage in the pelletization process. It aims to remove contaminants such as dirt, debris, labels, and residual chemicals from the shredded plastic. The washing process typically involves a combination of mechanical agitation, hot water, and cleaning agents to effectively clean the plastic particles.

Following the washing stage, the plastic particles are dried to eliminate any remaining moisture. Excessive moisture can cause issues during the extrusion process, affecting the quality and properties of the final pellets. Drying can be achieved through various methods, including hot air dryers, dehumidifiers, or centrifugal dryers.

Extrusion and Pellet Formation

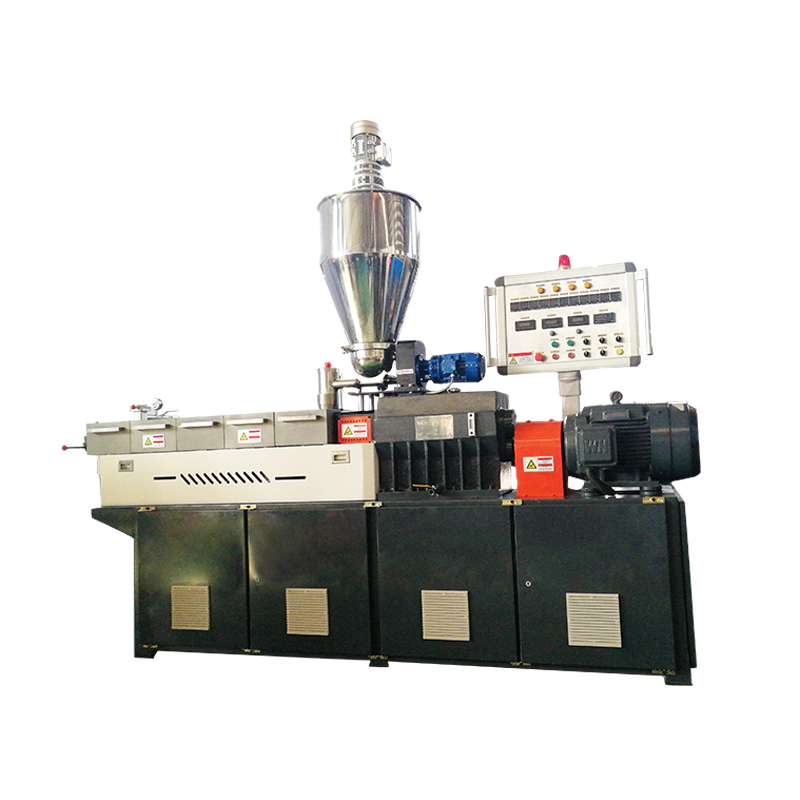

Extrusion and pellet formation is the final stage of the plastic pelletization process. The cleaned and dried plastic particles are fed into an extruder, a machine equipped with a rotating screw, which melts and homogenizes the plastic. The molten plastic is then forced through a small die, forming cylindrical strands.

As the strands exit the die, they are rapidly cooled in a water bath or air stream, causing them to solidify and harden. After the strands solidify, they are cut into desired lengths by a pelletizer or pellet cutting device. The resulting plastic pellets are uniform in size and shape, making them highly suitable for a wide range of applications.

The Significance of Plastic Pelletization

Plastic pelletization plays a crucial role in waste management and recycling efforts. Here are some key reasons why pelletizing plastic is significant:

1. Facilitates Recycling: Pelletizing plastic enables efficient recycling by transforming bulky plastic waste into more manageable and processable forms. The resulting pellets can be easily melted and reprocessed to create new plastic products, reducing the demand for virgin plastic.

2. Improves Storage and Transportation: Plastic pellets have a much higher bulk density compared to loose plastic waste. This means that a significantly larger volume of plastic waste can be stored and transported in pellet form, optimizing logistics and reducing costs.

3. Enhances Handling and Processing: The uniform size and shape of plastic pellets make them easier to handle, feed, and process in various industrial applications. Whether it is injection molding, extrusion, or blow molding, the consistent dimensions of pellets guarantee smooth and efficient processing.

4. Ensures Material Consistency: Pelletizing plastic ensures that the resultant pellets have uniform characteristics, such as composition, size, and shape. This consistency is crucial in applications where specific material properties are required, ensuring the desired performance and functionality of the end product.

5. Reduces Environmental Impact: By pelletizing plastic and promoting recycling, the amount of plastic waste that ends up in landfills or polluting the environment is significantly reduced. This contributes to the conservation of natural resources, minimizes pollution, and helps mitigate the environmental impact of plastic waste.

In conclusion, plastic pelletization offers an effective solution to the growing problem of plastic waste. By transforming plastic waste into small, uniform pellets, recycling becomes more efficient, storage and transportation are optimized, handling and processing are improved, material consistency is ensured, and environmental impact is reduced. With the increasing global concern for plastic pollution, the importance of pelletizing plastic cannot be understated. By embracing this process, we can take significant steps toward a more sustainable future.

Nanjing Tengda Machinery Co., Ltd. is deemed as one of the leading provider of Application products in China.

Nanjing Tengda Machinery Co., Ltd. intends to make enough profit to generate a fair return for our investors and to finance continued growth and development in Application.

Diversifying is an excellent growth strategy, as it allows TENGDA to have multiple streams of income that can often fill seasonal voids and, of course, increase sales and profit margins.

The manufacturing industry is changing fast, so, for Nanjing Tengda Machinery Co., Ltd., being able to pivot and adapt as the marketplace shifts is imperative.

You can get more information from TENGDA Extruder Machine Manufacturers for on sale. welcome to visit us and send your inquiry!