How to Select the Right Sheet Extruder Machine for Your Production Needs

How to Select the Right Sheet Extruder Machine for Your Production Needs

Introduction

Sheet extruder machines play a crucial role in various industries by enabling the production of high-quality plastic sheets. Whether you're in the packaging, automotive, or construction industry, selecting the right sheet extruder machine is essential for optimizing your production process. However, with a wide range of options available in the market, it can be overwhelming to make the right choice. In this article, we will guide you through the process of selecting the perfect sheet extruder machine for your specific production needs.

Understanding Your Production Needs

Before diving into the specifications and features of different extruder machines, it is crucial to have a clear understanding of your production requirements. Consider factors such as the material you will be extruding, sheet thickness, sheet width, desired output rate, and other specific needs unique to your industry. By having a comprehensive understanding of your requirements, you'll be able to narrow down your options and make an informed decision.

Key Factors to Consider

1. Material Compatibility

The first and foremost factor to consider when selecting a sheet extruder machine is its compatibility with the material you intend to extrude. Different machines are designed to handle specific types of materials, such as polyethylene (PE), polypropylene (PP), polystyrene (PS), and more. Ensure that the machine you choose is capable of processing your desired material efficiently, as using an incompatible machine can lead to poor sheet quality or even damage the equipment.

2. Extrusion Process and Features

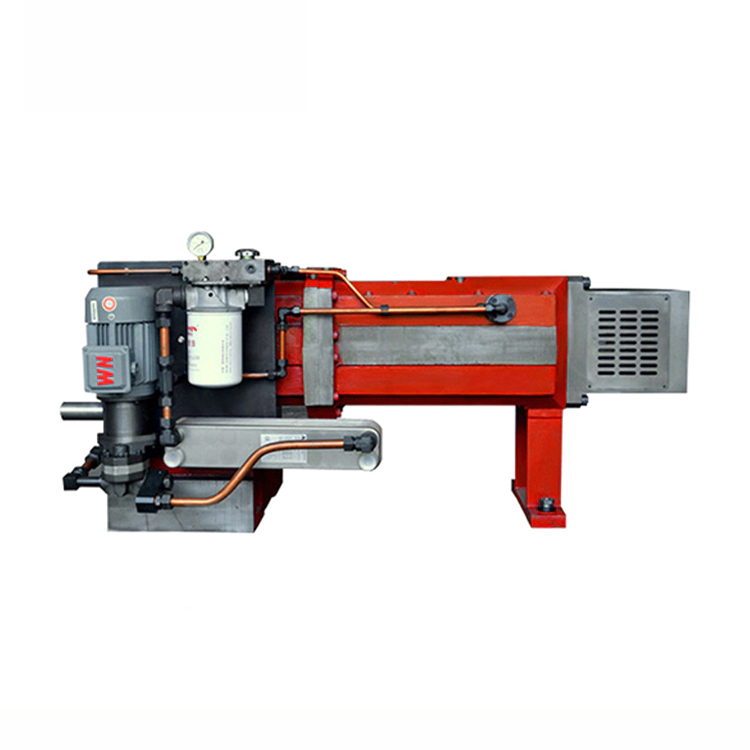

Next, evaluate the extrusion process and features offered by different machines. Consider aspects such as the type of extrusion process (single screw, twin screw, or co-extrusion), screw design, temperature control mechanisms, and motor horsepower. These factors directly impact the extruder's ability to produce consistent and high-quality sheets. Additionally, look for features like automatic thickness control, adjustable speed, and ease of maintenance to enhance productivity and flexibility.

3. Output

The desired output rate is another crucial consideration while selecting a sheet extruder machine. Determine your production requirements in terms of sheet width and thickness, as well as the expected daily output. Ensure that the machine you choose can meet your desired output rate without compromising quality. Moreover, consider the extruder's capability to handle future production growth, as investing in a machine that can accommodate increasing demands can save you from costly upgrades down the line.

4. Energy Efficiency

In today's environmentally conscious world, energy efficiency is a significant aspect to consider. Look for extruder machines that are designed to minimize energy consumption while maximizing output. Energy-efficient models not only help reduce operational costs but also have a smaller carbon footprint. Additionally, they often feature advanced control systems that optimize process parameters, resulting in consistent sheet dimensions and improved overall performance.

5. Reputation and Support from the Manufacturer

When investing in a sheet extruder machine, it is crucial to choose a reputable manufacturer known for their expertise and quality service. Research the manufacturer's reputation, customer reviews, and after-sales support to ensure you're making a reliable investment. A well-established manufacturer will not only provide a quality machine but will also offer technical support, spare parts availability, and prompt assistance in case of any issues.

Conclusion

Selecting the right sheet extruder machine is a critical decision that can significantly impact your production process and product quality. By understanding your production needs, evaluating key factors such as material compatibility, extrusion process and features, output, energy efficiency, and considering the reputation of the manufacturer, you can make an informed decision. Investing time and effort in selecting the right machine will help you optimize your production capabilities, reduce downtime, and produce high-quality plastic sheets tailored to your specific requirements.

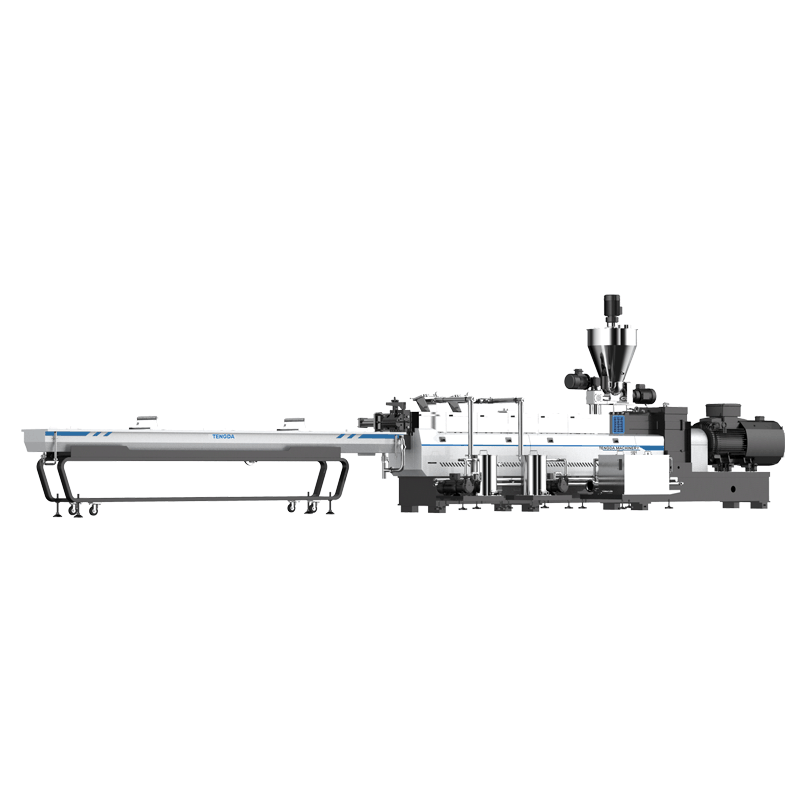

Nanjing Tengda Machinery Co., Ltd. helps high-profile clients build strategic relationships that drive company growth, investments, funding and more. There are many make-or-break details involved in the day-to-day manufacturing within our company.

Our vision is to realize the tremendous potential of Application by providing plastic extruder machine manufacturers services that consistently meet our customers’ expectations.

Visit TENGDA Extruder Machine Manufacturers for the best in extruder machine manufacturers Application supplies and get the most cost effective for your Application solution. Design and customization are also welcomed.