Improving Product Quality with a State-of-the-Art PP PS Sheet Extrusion Line

Introduction to PP PS Sheet Extrusion Lines

PP (Polypropylene) and PS (Polystyrene) are widely used thermoplastic materials in various industries. Their versatility, affordability, and excellent physical properties make them favorable choices for manufacturing a wide range of products, including food packaging, automotive components, electronics casings, and consumer goods. To meet the demand for high-quality PP PS sheets, manufacturers are continuously striving to improve their production processes. This article explores the significance of using state-of-the-art PP PS sheet extrusion lines in enhancing the product quality and overall efficiency of the manufacturing process.

Understanding the Basics of PP PS Sheet Extrusion

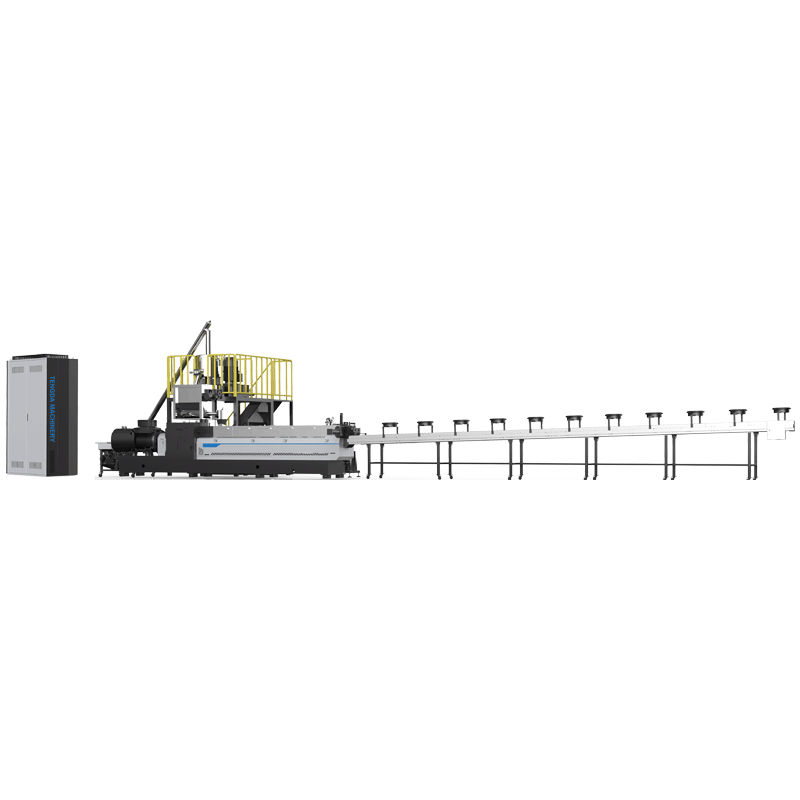

PP PS sheet extrusion is a process that involves melting the resin pellets and extruding them through a die to obtain a continuous film or sheet. The extrusion line consists of multiple components such as a hopper, extruder, screen changer, melt pump, die, cooling system, and haul-off system. These components work together sequentially to ensure uniform melting, proper mixing, reliable filtration, controlled sheet thickness, and efficient cooling. The developments in PP PS sheet extrusion technology have led to improved productivity and product quality.

Features and Advantages of State-of-the-Art PP PS Sheet Extrusion Lines

State-of-the-art PP PS sheet extrusion lines integrate advanced features and technologies to enhance their performance. These advancements include:

1. High Precision Control: Modern extrusion lines employ precise control systems that monitor parameters such as melt temperature, pressure, screw speed, and cooling conditions. This ensures consistent sheet thickness, adequate cooling for better dimensional stability, and minimal production variations.

2. Enhanced Material Handling: Advanced hopper designs, resin feed systems, and gravimetric or volumetric material feeding systems contribute to accurate resin dosing, minimizing material waste, and optimizing the extrusion process. Proper material handling enables consistent sheet quality.

3. Efficient Mixing and Homogenization: State-of-the-art extrusion lines employ twin-screw extruders with advanced screw designs to facilitate excellent resin melting, homogenization, and dispersion of additives or fillers. This ensures consistent material properties throughout the PP PS sheets, resulting in improved product quality.

4. Automated Filtration Systems: The inclusion of automatic screen changers and melt pumps with efficient filtration capabilities improves the sheet extrusion process's reliability. Contaminants or impurities are effectively removed, reducing the chances of defects in the final product.

5. Enhanced Cooling and Sheet Handling: Cooling systems with precise temperature control and adjustable air velocity aid in rapid cooling of the extruded sheet, reducing cycle times and enhancing productivity. Advanced haul-off systems provide better control over the sheet tension, minimizing distortion and enabling smooth sheet winding or further downstream processing.

Impacts on Product Quality and Manufacturing Efficiency

Integration of state-of-the-art PP PS sheet extrusion lines into manufacturing processes significantly impacts product quality and manufacturing efficiency. These effects are notable in various aspects:

1. Consistent Sheet Quality: The advanced control systems and material handling mechanisms ensure consistent material properties and sheet thickness. This leads to improved sheet quality, reducing the occurrence of defects such as warping, distortion, or inconsistent mechanical properties.

2. Enhanced Dimensional Stability: State-of-the-art extrusion lines offer precise temperature control during cooling, resulting in improved dimensional stability. This is crucial for products such as food packaging or electronic components that require accurate dimensions to meet industry standards and customer expectations.

3. Increased Production Output: The integration of modern extrusion lines streamlines the production process, minimizing downtime, and optimizing the use of resources. This improves production output, allowing manufacturers to meet increasing market demands efficiently.

4. Reduced Material Waste: The precise material handling systems and automated filtration mechanisms minimize material waste, leading to cost savings and a more sustainable manufacturing process.

5. Improved Productivity: With advanced control systems, optimized cooling, and efficient sheet handling, manufacturers can achieve faster cycle times and improve overall productivity while maintaining product quality.

Conclusion

The utilization of state-of-the-art PP PS sheet extrusion lines is instrumental in improving product quality, manufacturing efficiency, and overall competitiveness for manufacturers working with PP and PS materials. These extrusion lines harness the latest technological advancements to ensure consistent sheet quality, enhanced dimensional stability, increased production output, reduced waste, and improved productivity. By investing in such advanced equipment, manufacturers can meet the market's demands while delivering high-quality products, ultimately leading to business growth and customer satisfaction.

Nanjing Tengda Machinery Co., Ltd. will continue to build a corporate culture that respects and values the unique strengths and cultural differences of our associates, customers and community.

Dedicated to bringing you professional Application solutions and related products – from extruder machine manufacturers to plastic extruder machine manufacturers, Nanjing Tengda Machinery Co., Ltd. is your Application helper. Visit us at TENGDA Extruder Machine Manufacturers.

As consumers get more and better information regarding how to compare various products and companies, it is critical to compete on the price and value of Application.

need fuel for energy,while extruder machine manufacturers do not.

Application is produced by Nanjing Tengda Machinery Co., Ltd.’s professional skills in high technology.