Improving Productivity with a Modern Plastic Sheet Extrusion Line

Improving Productivity with a Modern Plastic Sheet Extrusion Line

Introduction:

Plastic sheet extrusion lines have revolutionized the manufacturing industry. With advancements in technology, these lines offer highly efficient processes that enhance productivity and output. This article explores the various ways in which modern plastic sheet extrusion lines are transforming the industry and improving productivity.

1. Introduction to Plastic Sheet Extrusion Lines:

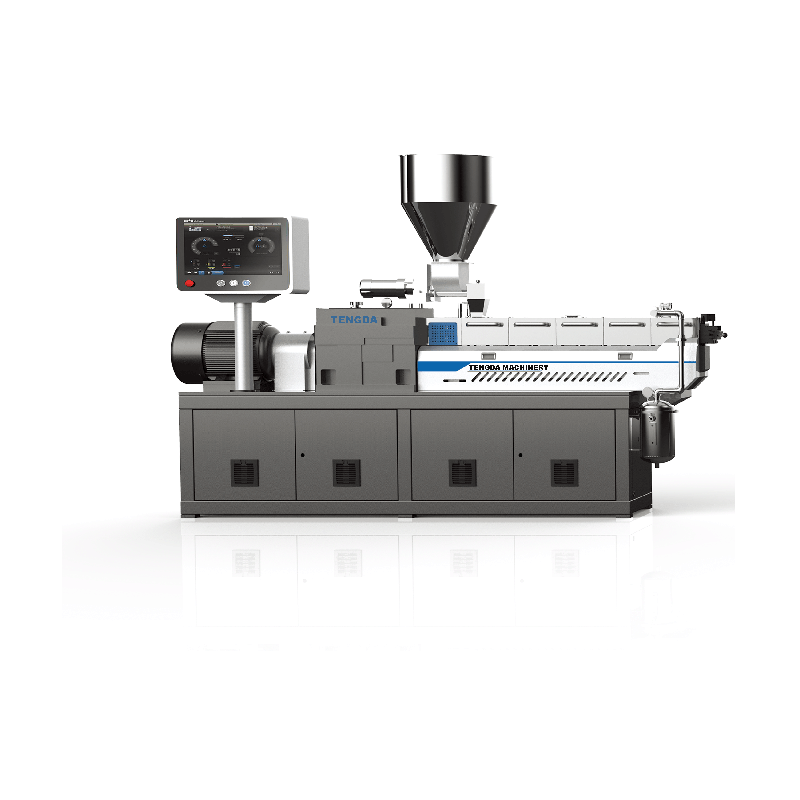

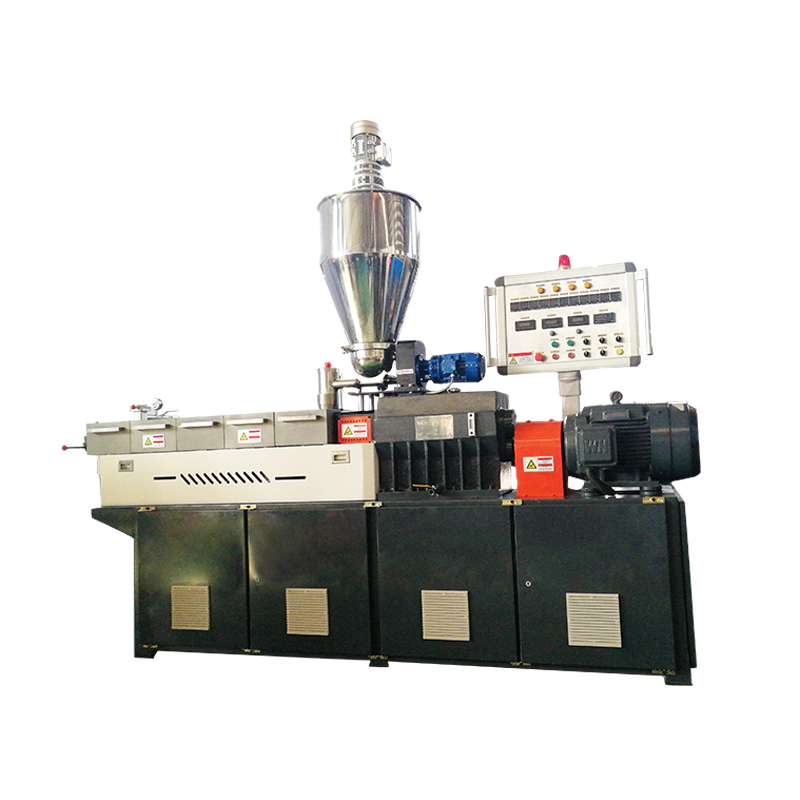

Plastic sheet extrusion lines are automated systems designed to produce high-quality plastic sheets in various shapes, sizes, and textures. These lines utilize raw plastic materials such as PET, PVC, polypropylene, and polystyrene, which are melted and shaped into thin sheets. The extrusion process involves feeding the plastic material through a hopper, melting it, and then passing it through a die to form a flat sheet before being cooled and trimmed to the desired size. The result is a versatile material that finds extensive applications in industries like packaging, construction, automotive, and more.

2. Advanced Technology for Enhanced Productivity:

Modern plastic sheet extrusion lines incorporate advanced technology to maximize productivity and efficiency. These lines are equipped with state-of-the-art control systems that allow for precise monitoring and adjustment of crucial parameters such as temperature, speed, and thickness. With integrated sensors and computerized controls, operators can fine-tune the process to ensure consistent quality and minimize waste.

3. Quick Changeover and Flexibility:

One of the significant advantages of modern plastic sheet extrusion lines is their ability to facilitate quick changeover between different materials and product specifications. By employing advanced processing techniques and tooling, these lines can swiftly switch between different plastic resins or modify the sheet thickness and width. This flexibility enables manufacturers to meet diverse customer demands and reduce downtime, resulting in increased productivity and profitability.

4. Improved Energy Efficiency:

Energy efficiency is a paramount concern in today's manufacturing landscape. Modern plastic sheet extrusion lines have undergone significant advancements in energy-saving technologies. Variable frequency drives (VFDs) and servo motors are now widely incorporated to precisely control the speed and power consumption of key components within the extrusion line. With the ability to optimize power usage based on the actual requirements, these systems drastically reduce energy waste and contribute to a greener and more sustainable production process.

5. Automated Quality Control Mechanisms:

Maintaining consistent product quality is crucial for any manufacturing process. Modern plastic extrusion lines feature automated quality control mechanisms that ensure every sheet produced meets the desired specifications. These systems employ sensors and cameras to monitor critical parameters such as thickness, width, and surface defects in real-time. Immediate feedback is provided to the operators, allowing them to take corrective actions promptly, thus minimizing the production of faulty sheets and reducing overall waste. This level of automation not only enhances productivity but also saves time and resources typically spent on manual inspection.

6. Integration of Industry 4.0 Principles:

The concept of Industry 4.0 has permeated various manufacturing sectors, and plastic sheet extrusion lines are no exception. These lines can now be seamlessly integrated with other smart factory components using industrial IoT (Internet of Things) technology. Real-time data collection and analysis enable predictive maintenance, optimization of production schedules, and intelligent decision-making. With interconnected systems, manufacturers can achieve higher levels of productivity, minimize downtime, and respond swiftly to changing market demands.

7. Training and Skill Development:

To fully harness the productivity benefits of modern plastic sheet extrusion lines, it is crucial to invest in employee training and skill development. The technological advancements incorporated in these lines require operators to possess a sound understanding of both mechanical and digital systems. By providing comprehensive training programs, manufacturers can empower their workforce to maximize the potential of the extrusion lines, leading to higher efficiency, fewer errors, and increased overall productivity.

Conclusion:

Modern plastic sheet extrusion lines have transformed the manufacturing industry, offering enhanced productivity, improved energy efficiency, and high-quality products. Their ability to facilitate quick changeover, provide automated quality control, and integrate with Industry 4.0 principles positions them as indispensable assets for manufacturers across various sectors. Embracing these advanced technologies and investing in skill development will enable companies to stay ahead of the competition and meet the ever-increasing demands of the market.

is a must have for anyone who appreciates plastic extruder machine manufacturers to the greatest extent.

Review Nanjing Tengda Machinery Co., Ltd.'s progress at regular intervals, so we can continue with the strategies that work well and change or eliminate the ones that don't give the results we are looking for.

Nanjing Tengda Machinery Co., Ltd. undertakes all maintenance duties for Application facilities and organizations and conducts all the security and surveillance for the properties.