Innovating Sustainability: The Future of Plastic Pelletizers

Plastic pollution has become an increasingly urgent global issue, with devastating impact on our environment. As we witness the catastrophic effects of plastic waste, there is a growing need for innovative and sustainable solutions to tackle this problem head-on. Enter plastic pelletizers, a revolutionary technology that offers a ray of hope in the battle against plastic pollution. In this article, we will delve into the cutting-edge advancements in plastic pelletizers and explore their potential to shape a sustainable future.

The Rise of Plastic Pelletizers

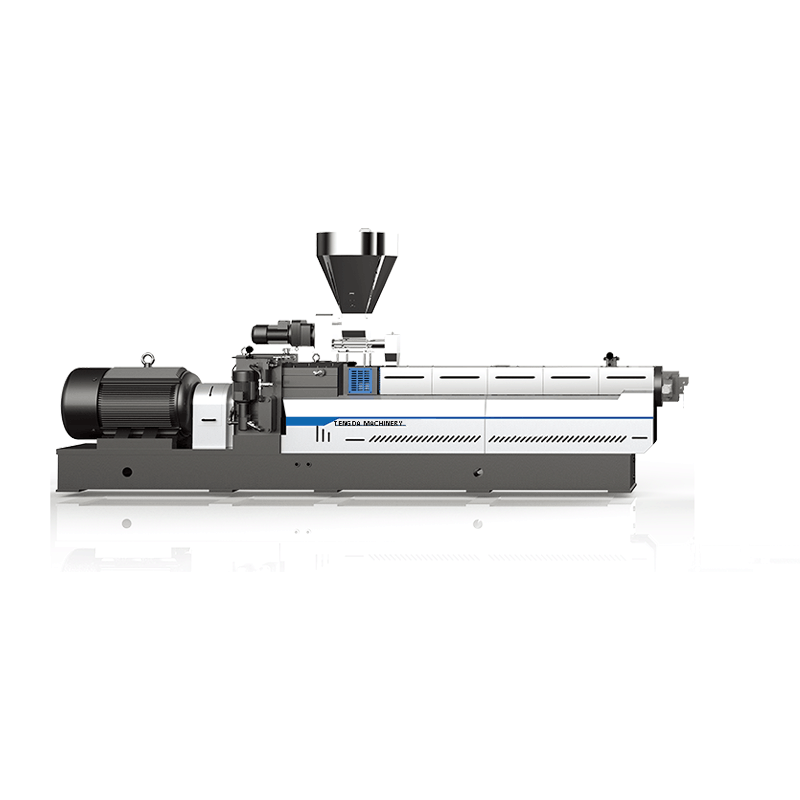

Plastic pelletizers, also known as plastic granulators, are machines designed to transform plastic waste into small pellets or granules. These pellets can then be used to manufacture new plastic products, creating a closed-loop recycling system. The concept of pelletizing plastics originated in the 1950s, but it has evolved significantly over the years, becoming an efficient and effective solution to combat plastic pollution.

Plastic pelletizers serve as a crucial link between plastic waste and the creation of new products. By breaking down and repurposing plastic waste, these machines have the potential to minimize the demand for new plastic production, reducing our reliance on fossil fuels and curbing greenhouse gas emissions. With the recent advancements in this technology, plastic pelletizers are shaping up to be a game-changer in the realm of sustainability.

The Advantages of Plastic Pelletizers

Plastic pelletizers offer a myriad of advantages over traditional recycling methods, making them a preferred choice in the industry. Here are some key benefits:

1. Efficient Resource Utilization:

The use of plastic pelletizers allows for the reuse of plastic waste, preventing it from clogging landfills or winding up in our oceans. By converting plastic waste into small, uniform pellets, the material can be easily transported, stored, and utilized as a valuable resource in the manufacturing sector.2. Cost-effectiveness:

Compared to other recycling processes, plastic pelletizers offer significant cost savings. The use of recycled plastic pellets reduces reliance on virgin resin, which can be expensive. Additionally, the compact and efficient design of modern pelletizers minimizes energy consumption and labor requirements, further improving cost-effectiveness.3. Quality Control:

Plastic pelletizers employ advanced technologies to ensure high-quality output. These machines can effectively separate foreign objects, such as paper or metals, from the plastic waste, resulting in clean and pure pellets. The use of quality control mechanisms guarantees that the recycled plastic meets the required standards, enabling its use in a wide range of applications.4. Versatility:

Plastic pelletizers are designed to process various types of plastics, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polystyrene (PS). This versatility enables the recycling of a wide range of plastic waste, contributing to the reduction of overall plastic pollution.5. Reduced Environmental Footprint:

By diverting plastic waste from landfills and incinerators, plastic pelletizers play a pivotal role in reducing the environmental impact of plastic pollution. The use of recycled plastic pellets also reduces the need for virgin resin production, which requires significant amounts of energy and contributes to carbon emissions.Technological Advancements in Plastic Pelletizers

In recent years, there have been remarkable advancements in the field of plastic pelletizers. These innovations have further enhanced the efficiency, productivity, and sustainability of this technology. Let's explore some of the key technological advancements in plastic pelletizers:

1. Automated Sorting and Segregation:

Traditional recycling processes often rely on manual sorting, which is time-consuming and susceptible to errors. Modern plastic pelletizers incorporate automated sorting systems using optical sensors and advanced algorithms. These systems can detect and segregate different types of plastics, ensuring high-quality output and streamlining the recycling process.2. Energy Efficiency:

Efforts to reduce energy consumption and improve efficiency have been a significant focus in the development of plastic pelletizers. The latest models feature energy-efficient motors, optimized heating and cooling systems, and advanced insulation techniques to minimize heat loss. This not only lowers operating costs but also reduces the overall environmental impact of the recycling process.3. Smart Control Systems:

The integration of smart control systems in plastic pelletizers has revolutionized their operation and maintenance. These systems offer real-time monitoring and control, allowing operators to optimize parameters such as temperature, pressure, and throughput. The advanced analytics provided by smart control systems enable proactive maintenance, ensuring maximum uptime and productivity.4. Innovative Feedstock:

The ongoing research and development in the field of feedstock have led to the introduction of innovative materials in plastic pelletizers. These include biodegradable plastics, bio-based plastics, and even mixed plastic waste that was previously considered non-recyclable. The ability to process a diverse range of feedstock expands the possibilities of plastic recycling, contributing to a more sustainable future.5. Integration of Renewable Energy:

To further enhance sustainability, plastic pelletizers are increasingly being integrated with renewable energy sources. By utilizing solar, wind, or hydropower to meet their energy requirements, these machines significantly reduce carbon emissions associated with the recycling process. This integration paves the way for a greener and more sustainable approach to plastic waste management.The Future Outlook

Plastic pelletizers have emerged as a visionary solution to address the mounting plastic pollution crisis. As technological advancements continue to drive innovation in this field, the future of plastic pelletizers looks promising. The integration of artificial intelligence, machine learning, and robotics is expected to revolutionize the recycling industry, further streamlining the operation and efficiency of plastic pelletizers.

Moreover, collaborations between governments, industries, and research institutions are critical in fostering a supportive environment for plastic pelletizers. Increased investment in research and development can unlock the full potential of this technology, leading to continuous improvements and advancements. By embracing plastic pelletizers and other sustainable solutions, we can pave the way for a circular economy, where plastic waste is minimized, and resources are valorized.

In conclusion, plastic pelletizers offer a beacon of hope in the battle against plastic pollution. These innovative machines hold the key to a sustainable future by transforming plastic waste into valuable resources. With their numerous advantages and ongoing technological advancements, plastic pelletizers have the potential to revolutionize the recycling industry and contribute to a cleaner and healthier planet. It is up to us to embrace and support these technologies, ensuring that we leave a better world for future generations. Together, let us innovate sustainability and forge a path towards a plastic-free future.

When you find yourself in need of Application extruder machine manufacturers, you may not know where to begin. And that's OK! Search out Nanjing Tengda Machinery Co., Ltd. to handle your Application needs.

Get plastic extruder machine manufacturers Application from only reliable exporters, go to TENGDA Extruder Machine Manufacturers for more details.

Application can be great additions to companies looking to improve the well-being of their employees, as well as increase the efficiency and productivity of their workers across the organization.

The extruder machine manufacturers Application has significantly numerous benefits over other plastic extruder machine manufacturers systems, which makes it first choice for extruder machine manufacturers.

Nanjing Tengda Machinery Co., Ltd. can promise you that we never conceded on the quality standards of our products.