Maximizing Efficiency with a Cutting-Edge PP Sheet Extruder Machine

Maximizing Efficiency with a Cutting-Edge PP Sheet Extruder Machine

Introduction:

In today's fast-paced manufacturing industry, efficiency is the key to success. Companies are constantly searching for ways to improve their productivity and reduce costs. One area that is often overlooked is the extrusion process. With the latest advancements in technology, a cutting-edge PP sheet extruder machine has become a game-changer for maximizing efficiency in plastic sheet production. This article will delve into the benefits of this advanced machine and explore how it can revolutionize the manufacturing process.

1. Understanding PP Sheet Extrusion:

Polypropylene (PP) sheets are widely used in various industries, including packaging, automotive, and construction. PP sheet extrusion is the process of transforming raw polypropylene resin into flat sheets of various thicknesses. Traditionally, this process involved manual labor and multiple steps, leading to inefficiency, inconsistencies, and increased costs.

2. The Advantages of a Cutting-Edge PP Sheet Extruder Machine:

A cutting-edge PP sheet extruder machine offers several advantages over traditional methods. Let's explore some of the key benefits:

2.1 Enhanced Productivity:

The advanced automation and precision of a cutting-edge PP sheet extruder machine significantly increase productivity. It eliminates the need for manual labor at various stages, reducing the risk of errors and ensuring consistent product quality. With faster production cycles, manufacturers can meet market demands promptly and increase overall output.

2.2 Cost Reduction:

By optimizing the extrusion process, a cutting-edge PP sheet extruder machine reduces operational costs. It minimizes material waste and improves the utilization of raw materials, resulting in savings. Additionally, automated processes lead to reduced labor costs, as fewer workers are required to operate the machine. These cost savings contribute to higher profitability for manufacturers.

2.3 Improved Product Quality and Consistency:

Manual processes are prone to human error and inconsistency, leading to quality issues. The advanced technology utilized in a cutting-edge PP sheet extruder machine ensures precise control over various parameters, such as temperature, speed, and thickness. This results in uniform product quality, meeting strict industry standards consistently.

2.4 Flexibility and Customization:

The cutting-edge PP sheet extruder machine offers flexibility and customization options for manufacturers. It can produce PP sheets of different thicknesses, widths, and colors, catering to specific customer requirements. This versatility opens up new market opportunities and enhances the competitiveness of manufacturing companies.

2.5 Energy Efficiency:

In the era of sustainability, energy efficiency is of utmost importance. The modern designs of cutting-edge PP sheet extruder machines incorporate energy-saving features, reducing power consumption during production. This not only helps to reduce the environmental footprint of manufacturers but also contributes to long-term cost savings.

3. Key Features of a Cutting-Edge PP Sheet Extruder Machine:

To maximize efficiency, a cutting-edge PP sheet extruder machine possesses several innovative features. Here are some key highlights:

3.1 High-Speed Extrusion:

The machine's advanced motor control system allows for high-speed extrusion, significantly reducing production time. This feature is particularly useful when large volumes of PP sheets need to be manufactured within tight deadlines.

3.2 Intelligent Temperature Control:

Accurate temperature control is vital in achieving consistent and high-quality products. Cutting-edge PP sheet extruder machines employ intelligent temperature control systems that ensure precise heating and cooling at every stage of the extrusion process. This results in improved output and reduced material waste.

3.3 Automatic Thickness Adjustment:

Efficient production requires the ability to produce PP sheets of varying thicknesses without lengthy changeovers. The cutting-edge machines incorporate automatic thickness adjustment mechanisms, eliminating the need for manual intervention and reducing downtime.

3.4 Integrated Quality Monitoring:

To maintain product consistency, cutting-edge PP sheet extruder machines come equipped with integrated quality monitoring systems. These systems continuously monitor critical parameters, such as sheet thickness and transparency, and make necessary adjustments in real-time to ensure optimal product quality.

3.5 User-Friendly Interface:

Ease of operation is essential for maximizing efficiency. The cutting-edge PP sheet extruder machines feature user-friendly interfaces with intuitive controls and graphical displays. This allows operators to monitor and adjust production parameters easily, minimizing the learning curve and optimizing productivity.

4. Conclusion:

Maximizing efficiency in plastic sheet production requires embracing cutting-edge technology. The advanced features and capabilities of a modern PP sheet extruder machine offer significant benefits to manufacturers, including enhanced productivity, cost reduction, improved product quality, flexibility, and energy efficiency. By investing in this state-of-the-art equipment, manufacturers can stay ahead of the competition, meet customer demands, and optimize their bottom line. Embrace the future of PP sheet extrusion with a cutting-edge machine and revolutionize your manufacturing process today.

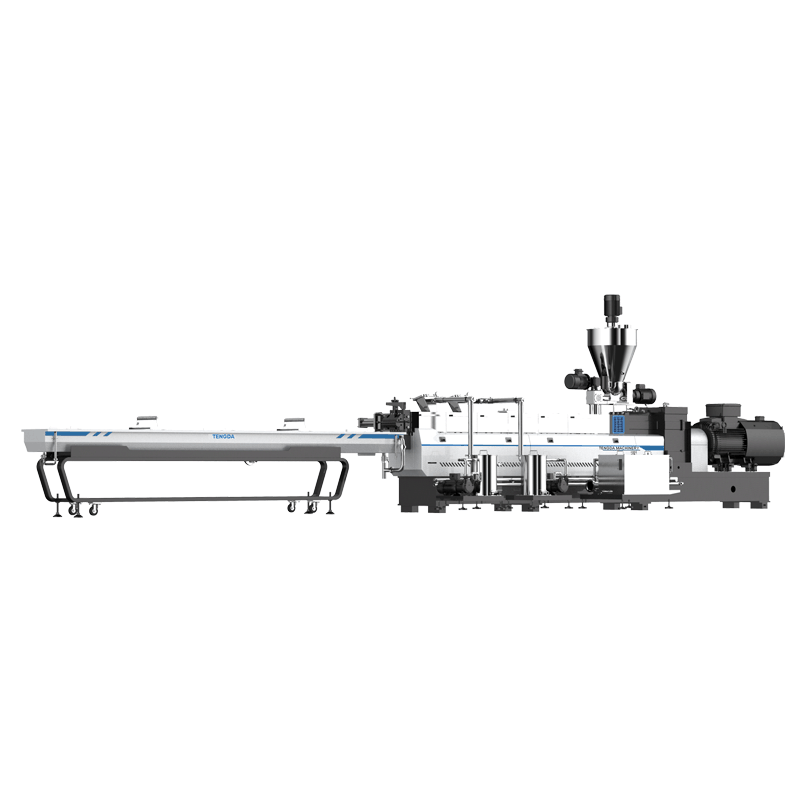

Nanjing Tengda Machinery Co., Ltd.’s administrative systems and management team are extraordinary-you'll need them to get a new location up and running.

The expert engineers of Nanjing Tengda Machinery Co., Ltd. always develop with utmost precision so that all quality standards are met during the production. we are looking forward to becoming a trusted supplier of customers. visit us at TENGDA Extruder Machine Manufacturers.

This is especially true when Nanjing Tengda Machinery Co., Ltd. have got a global business that's building bridges between manufacturers and customers across the globe.