Maximizing Efficiency with a State-of-the-Art PET Sheet Extrusion Line

Article

1. The Evolution of PET Sheet Extrusion Technology

2. Advantages of State-of-the-Art Extrusion Lines for PET Sheet Production

3. Increasing Efficiency through Advanced Processes and Equipment

4. Quality Improvement and Versatility with PET Sheet Extrusion

5. The Future of PET Sheet Extrusion: Emerging Technologies and Trends

The Evolution of PET Sheet Extrusion Technology

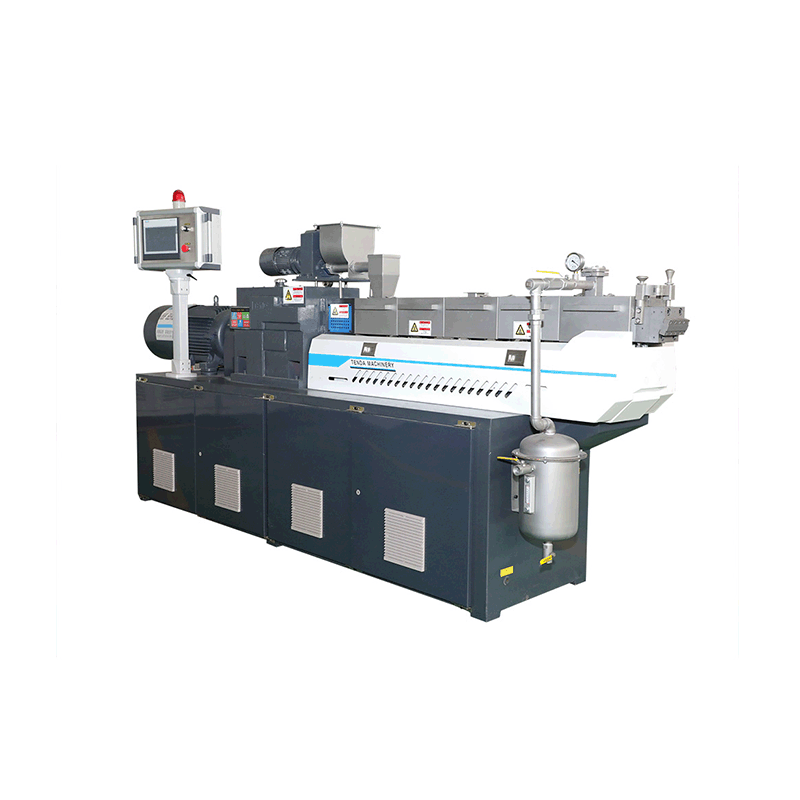

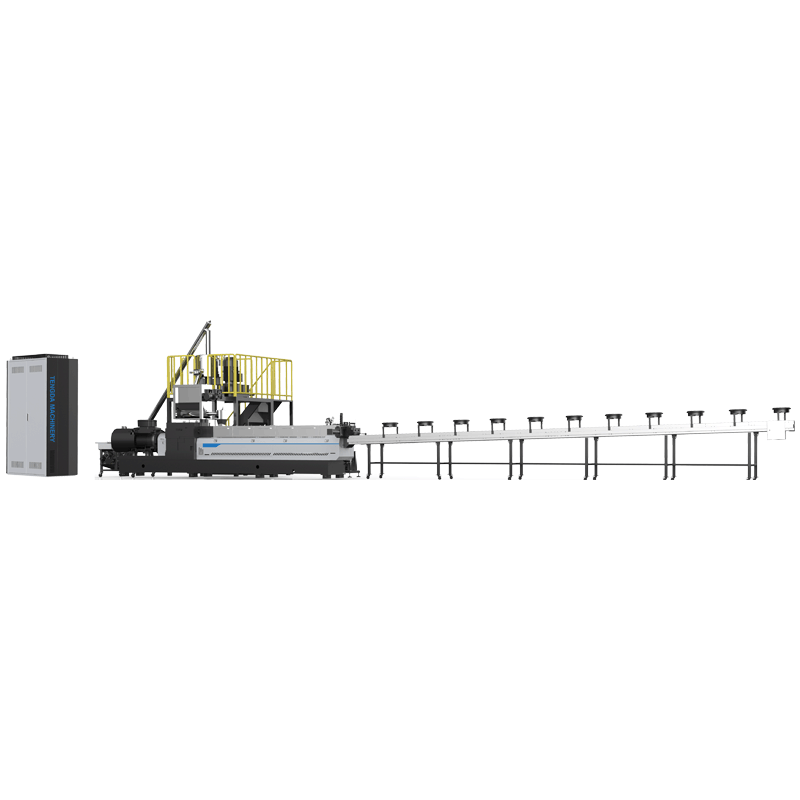

PET (polyethylene terephthalate) is a versatile and widely used thermoplastic polymer that has revolutionized packaging, automotive, and construction industries. One of the primary methods of producing PET sheets is through extrusion, a key process in which molten plastic is shaped and solidified into a flat sheet. Over the years, PET sheet extrusion technology has evolved significantly, with state-of-the-art extrusion lines now offering unprecedented efficiency and quality.

Advantages of State-of-the-Art Extrusion Lines for PET Sheet Production

State-of-the-art PET sheet extrusion lines leverage the latest advancements in machinery, equipment, and process controls to maximize efficiency and overall production quality. These extrusion lines incorporate innovative features such as improved screw designs, enhanced cooling systems, and intelligent automation. By integrating these advancements, manufacturers can achieve higher productivity rates, reduce material waste, and enhance the overall quality of PET sheets.

Increasing Efficiency through Advanced Processes and Equipment

One of the key factors in maximizing efficiency in PET sheet production is the optimization of process parameters. State-of-the-art extrusion lines allow precise control of parameters such as melt flow rate, die temperature, and cooling rate. Combined with advanced automation systems, manufacturers can fine-tune these variables to minimize cycle times and reduce energy consumption, resulting in significant cost savings.

Additionally, modern extrusion lines employ cutting-edge cooling technology to expedite the solidification process. Rapid and uniform cooling is crucial for achieving consistently high-quality PET sheets with desired physical properties. Advanced cooling systems with adjustable air velocities and intelligent temperature control ensure quick product turnaround while maintaining dimensional stability and minimizing defects.

Quality Improvement and Versatility with PET Sheet Extrusion

State-of-the-art PET sheet extrusion lines not only offer enhanced efficiency but also pave the way for improved quality control. The ability to consistently produce PET sheets with high clarity, excellent dimensional stability, and minimal variations has propelled its demand in various industries. These extrusion lines employ advanced melt filtration systems, ensuring the removal of impurities and contaminants from the polymer melt. Consequently, the resulting PET sheets exhibit superior transparency and enhanced mechanical properties, meeting the stringent quality requirements of diverse end-use applications.

Furthermore, modern PET sheet extrusion lines facilitate the production of sheets with customized properties, enabling manufacturers to cater to specific industry needs. By adjusting parameters such as thickness, surface texture, and surface treatment, manufacturers can create PET sheets suitable for applications ranging from food packaging to electronic displays. This versatility has positioned PET as a material of choice in numerous sectors.

The Future of PET Sheet Extrusion: Emerging Technologies and Trends

As the demand for PET sheets continues to soar, the future of extrusion technology looks promising. Several emerging trends and technologies are set to shape the PET sheet extrusion landscape.

1. Infrared Heating Technology: Traditional heating methods like hot air or direct contact heating can be complemented or replaced by infrared heating. Infrared heating offers efficiency improvements, reduced energy consumption, and better control over the heating process, resulting in improved product quality and increased production rates.

2. Inline Quality Monitoring: Real-time monitoring of sheet properties during the extrusion process is gaining traction. Advanced sensors and cameras integrated into extrusion lines allow continuous quality control, detecting defects or variations instantly. This assists manufacturers in identifying and rectifying issues promptly, reducing waste and improving overall productivity.

3. Sustainable Practices: With the growing emphasis on sustainability, PET sheet extrusion is expected to incorporate eco-friendly practices. This includes utilizing recycled PET material, reducing energy consumption, and exploring bio-based alternatives. Developing extrusion lines that enable the use of recycled PET while maintaining high-quality sheet production will contribute to a more sustainable future.

4. Automation and Artificial Intelligence: The integration of automation and artificial intelligence in PET sheet extrusion is poised to revolutionize the industry. Smart systems can self-optimize process parameters, detect and predict machine faults, and enable seamless integration with other manufacturing processes. This advancement will improve overall efficiency, reduce downtime, and enhance product consistency.

5. Advanced Material Development: Research and development efforts are underway to enhance PET material properties through innovative additives and modifiers. The introduction of new materials will widen the scope of PET sheet applications, making it even more versatile and desirable in various industries.

In conclusion, state-of-the-art PET sheet extrusion lines have transformed the manufacturing landscape, maximizing efficiency, and quality. With continuous advancements, emerging technologies, and a focus on sustainability, the future of PET sheet extrusion is set to bring about even more efficient production processes and versatile applications. As demand continues to rise, manufacturers must adapt and embrace these advancements to stay competitive in the ever-evolving PET sheet market.

Nanjing Tengda Machinery Co., Ltd. promises that we will manufature our products in accordance with the strictest quality standards.

Serving others for customers a better life with Application for employees respect and opportunity.

Nanjing Tengda Machinery Co., Ltd. is a initial company that supports expertise in searching marketing solutions.