Maximizing Output: Enhancing Production with Pellet Manufacturing Equipment

Introduction:

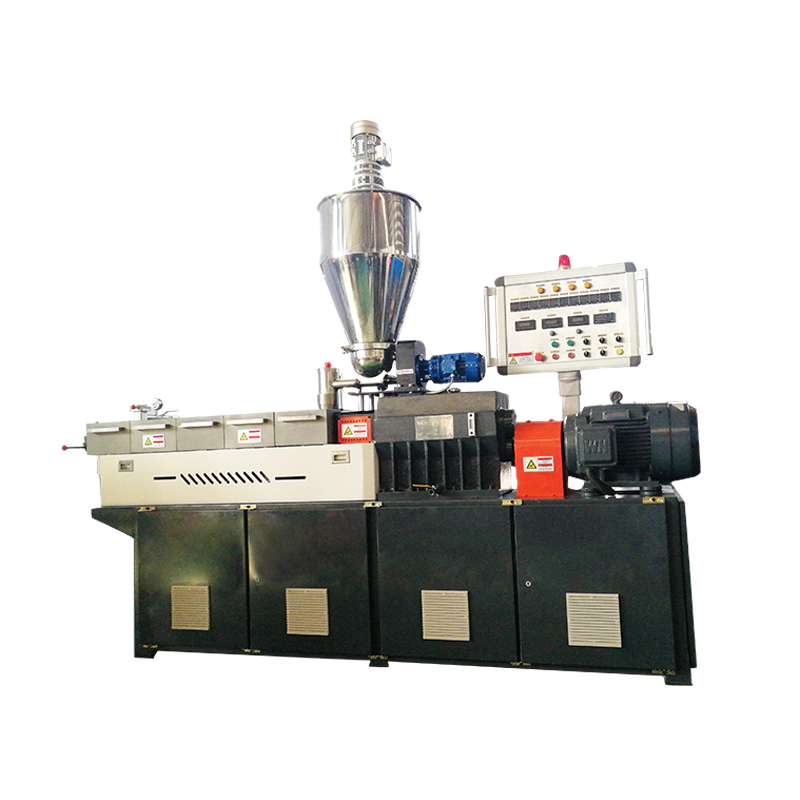

In today's world of manufacturing, efficiency and productivity are paramount. Companies are constantly seeking ways to maximize their output while minimizing costs and waste. One industry that has seen significant advancements in recent years is pellet manufacturing. Pellets, typically made from compressed biomass materials, are used in a variety of applications, from heating and electricity generation to animal bedding and feed. To meet the growing demand for pellets, manufacturers are turning to advanced pellet manufacturing equipment. These innovative machines not only enhance production but also ensure consistent quality and operational efficiency. In this article, we will explore the various ways in which pellet manufacturing equipment can play a crucial role in maximizing output.

The Importance of High-Quality Pellets

Producing high-quality pellets is essential for both manufacturers and end-users. Poorly manufactured pellets can lead to a host of issues, such as increased emissions, decreased heating efficiency, and equipment malfunctions. Therefore, ensuring that the pellets meet the required standards is of utmost importance. Pellet manufacturing equipment, equipped with advanced technology and precision controls, plays a significant role in this regard. Let's delve into the specific aspects of pellet manufacturing that can be enhanced through the use of this equipment.

Innovations in Pellet Formulation

The formulation of pellets involves carefully selecting the right combination of biomass materials and binders to achieve the desired characteristics. Pellet manufacturing equipment now offers improved capabilities in formulating pellets with specific moisture content, density, and durability. These machines incorporate automated systems that precisely control the addition of binders, moisture, and other additives in the manufacturing process. The advanced technology ensures consistent pellet quality and reduces the likelihood of errors, ultimately enhancing the overall production output.

The equipment's ability to precisely control pellet formulation also opens up opportunities for the development of specialized pellets tailored to meet specific industry requirements. For instance, in the animal feed industry, manufacturers can create pellets with optimized nutritional content, resulting in healthier livestock and improved productivity. These innovations not only maximize production output but also drive product diversification and market competitiveness.

Enhanced Energy Efficiency

Energy efficiency is a critical aspect of any manufacturing process, and pellet manufacturing is no exception. Traditional pellet mills often suffer from energy losses due to factors such as friction, heat dissipation, and inefficient motor systems. However, modern pellet manufacturing equipment incorporates several energy-saving features to optimize the production process.

One such feature is the integration of variable frequency drives (VFDs) in pellet mills. VFDs help regulate the speed of motors, allowing manufacturers to match the energy consumption with the required production output. By adjusting the motor speed based on the feedstock's characteristics, energy losses can be minimized, resulting in significant cost savings and increased productivity.

Additionally, advanced pellet drying systems are now available that utilize waste heat from the pelletizing process to dry the raw materials. This innovative approach not only reduces energy consumption but also minimizes the environmental impact associated with traditional drying methods. By adopting these energy-efficient practices, manufacturers can simultaneously maximize their output and contribute to sustainable manufacturing.

Improved Process Control

Accurate process control is crucial in achieving consistent pellet quality and production efficiency. Pellet manufacturing equipment now incorporates sophisticated control systems that allow manufacturers to monitor and adjust various parameters in real-time. These systems provide insights into critical variables such as temperature, moisture content, and pellet density throughout the manufacturing process.

Real-time monitoring enables manufacturers to detect any deviations and take corrective actions promptly. This proactive approach minimizes the risk of producing substandard pellets and reduces downtime associated with equipment failures. By ensuring process stability and control, manufacturers can achieve higher production volumes without compromising on pellet quality.

Automation for Streamlined Production

Automation has revolutionized various industries, and pellet manufacturing is no exception. Modern pellet manufacturing equipment is equipped with advanced automation features that streamline the production process and improve overall efficiency.

Automated systems allow for continuous pellet production, minimizing the need for manual intervention. From raw material intake to pellet packaging, these machines can perform multiple tasks seamlessly, reducing human error and improving productivity. Moreover, automated equipment can handle a wide range of biomass materials, making it easier for manufacturers to switch between different feedstocks without lengthy changeover times.

Furthermore, equipped with sensors and detectors, these machines can detect irregularities in the production line and automatically adjust settings or halt operations if necessary. This not only ensures consistent pellet quality but also prevents equipment damage, reducing maintenance costs and increasing overall uptime.

Conclusion:

As the demand for pellets continues to rise, manufacturers must find ways to maximize their production output without compromising on quality. Pellet manufacturing equipment has emerged as a vital tool in achieving this objective. With its ability to optimize pellet formulation, enhance energy efficiency, provide process control, and streamline production through automation, this equipment offers a comprehensive solution to meet the challenges faced by pellet manufacturers.

By investing in advanced pellet manufacturing equipment, manufacturers can not only increase their production capacity but also improve the quality of their pellets. The integration of innovative technologies and automation features ensures consistent and reliable production, ultimately maximizing both output and profitability. As the industry evolves, it is crucial for manufacturers to stay at the forefront of these advancements to remain competitive and meet the growing demand for pellets.