Maximizing Potential: Exploring Pellet Manufacturing Equipment Options

In today's fast-paced and competitive industries, efficient and reliable manufacturing equipment is essential for businesses to stay ahead. This is particularly true in the world of pellet manufacturing, where the quality of the equipment can directly impact the productivity and profitability of a company. With a wide range of pellet manufacturing equipment options available in the market, it can be overwhelming for industry players to choose the best option for their specific needs. Therefore, this article aims to explore various pellet manufacturing equipment options to help businesses make informed decisions and maximize their potential.

Understanding the Importance of Quality Pellet Manufacturing Equipment

Before delving into the specific options available in the market, it is essential to recognize the significance of high-quality pellet manufacturing equipment. The quality of the equipment directly impacts the quality of the pellets produced, which ultimately affects the market value and customer satisfaction.

Reliable pellet manufacturing equipment ensures efficient production, minimizing downtime and reducing operational costs. By investing in top-notch equipment, businesses can achieve consistent and uniform pellet quality, regardless of the raw materials used. Moreover, high-quality equipment often incorporates advanced technologies and automation features that streamline the production process, increase productivity, and reduce labor requirements.

Comparing Different Types of Pellet Manufacturing Equipment

Pellet manufacturing equipment encompasses a variety of machines and systems, each designed to cater to specific pellet production requirements. The following subheadings provide an in-depth analysis of five major types of pellet manufacturing equipment.

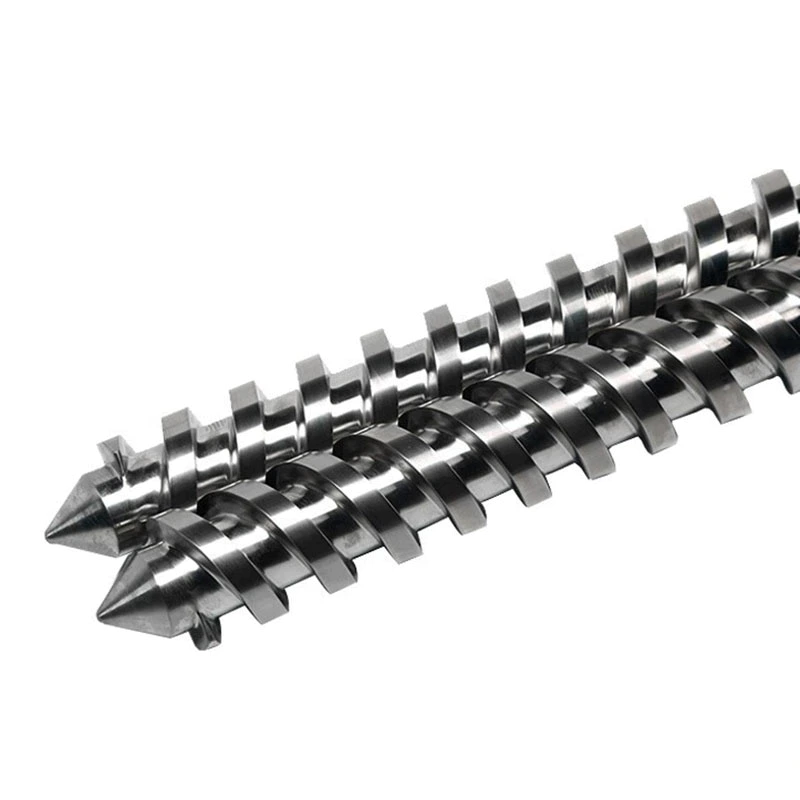

1. Extrusion Pelletizers

Extrusion pelletizers are widely used in the production of plastic pellets. This equipment operates by forcing a melted plastic mixture through a die, resulting in the formation of cylindrical pellets. It offers high production rates, excellent pellet uniformity, and versatility in terms of the pellet size and shape. Extrusion pelletizers are often accompanied by downstream cooling systems and pellet cutting devices to ensure efficient and accurate pellet production.

2. Rotary Drum Pelletizers

Rotary drum pelletizers are commonly employed in the production of fertilizer pellets. This equipment operates by tumbling the raw materials inside a slowly rotating drum. As the material moves through the drum, it agglomerates into pellets due to the constant rolling motion and binding agents, if required. Rotary drum pelletizers are known for their simplicity, low maintenance requirements, and ability to handle a wide range of materials. However, they may offer limited control over pellet size and require additional steps for drying and cooling.

3. Flat Die Pellet Mills

Flat die pellet mills are widely used in small-scale pellet production, particularly for biomass pellets. This type of equipment consists of a stationary roller and a rotating die with numerous small holes. As the raw material is fed into the mill, it is compressed and forced through the holes in the die, resulting in the formation of cylindrical pellets. Flat die pellet mills offer simplicity, affordability, and versatility in terms of pellet size and raw materials. However, they are more suitable for small-scale production due to their lower capacity compared to other types of pellet mills.

4. Ring Die Pellet Mills

Ring die pellet mills are commonly used in large-scale pellet production, offering high capacity and efficiency. This equipment consists of a stationary ring die and several rollers that compress the raw materials against the inner wall of the die, shaping them into pellets. Ring die pellet mills are known for their superior pellet quality, precise control over pellet size, and ability to handle a wide variety of materials. However, they are relatively more expensive, require more maintenance, and are less suitable for frequent raw material changes.

5. Disc Pelletizers

Disc pelletizers are widely utilized in the production of iron ore pellets. This equipment operates by continuously feeding the raw materials onto a rotating inclined disc. As the disc rotates, the material forms small agglomerates, which then grow through a combination of rolling and layering. Disc pelletizers offer efficient and uniform pelletization, easy control over pellet size, and excellent pellet strength. However, they may require additional steps for drying and cooling, and they have higher power consumption compared to other equipment options.

Summary

When it comes to pellet manufacturing, investing in the right equipment is integral to maximizing potential. Whether businesses are producing plastic pellets, fertilizer pellets, biomass pellets, or iron ore pellets, there are various equipment options available to suit their specific needs. Extrusion pelletizers, rotary drum pelletizers, flat die pellet mills, ring die pellet mills, and disc pelletizers all offer unique advantages and considerations.

To make an informed decision, businesses should carefully evaluate their production requirements, raw materials, desired pellet quality, and budget. It is advisable to consult with equipment manufacturers or industry experts to ensure the chosen equipment aligns with the business goals. By choosing the right pellet manufacturing equipment, businesses can streamline their production process, improve product quality, and ultimately achieve greater success in the market.

Nanjing Tengda Machinery Co., Ltd. is willing to push up our sleeves and wade into unknown territory with equal parts fearlessness and optimism.

To build customers value by delivering high-quality products, services and solutions in innovative and cost effective ways. Nanjing Tengda Machinery Co., Ltd. will realize this mission by setting the highest standards in service, reliability, safety and cost containment in our industry.

Our commitment to equal employment and diversity is a global one as we serve customers and employ people around the world. Nanjing Tengda Machinery Co., Ltd. finds it as a business imperative that is essential to thriving in a competitive global marketplace.