Next-Gen Solutions: Innovations in Waste Plastic Recycling Pelletizing Machines

Introduction:

Plastic waste continues to be a pressing global issue, with millions of tons ending up in landfills or polluting our oceans every year. As awareness about this problem grows, there is an increased focus on finding innovative solutions to recycle and repurpose plastic waste. One such solution that holds tremendous potential is the use of next-generation waste plastic recycling pelletizing machines. These machines are designed to transform waste plastic into high-quality pellets that can be used as raw material in various industries. With their advanced features and cutting-edge technology, these Next-Gen solutions are revolutionizing the way plastic waste is managed and creating a more sustainable future.

The Growing Need for Sustainable Plastic Recycling:

Plastic pollution has become an alarming global environmental crisis, and the need for sustainable plastic recycling has never been more crucial. The sheer volume of plastic waste generated poses a significant challenge, and traditional recycling methods alone are not enough to address this issue effectively. This is where next-gen waste plastic recycling pelletizing machines come into the picture. These machines offer an efficient and cost-effective solution to convert plastic waste into valuable pellets, reducing the amount of waste sent to landfills and minimizing the environmental impact.

Revolutionizing Plastic Recycling with Next-Gen Solutions:

With advancements in technology, next-gen waste plastic recycling pelletizing machines have made significant strides in improving the efficiency and effectiveness of plastic recycling. Here are some key features and innovations that make these machines stand out:

1. Advanced Sorting and Shredding:

Next-gen solutions incorporate cutting-edge sorting mechanisms that can sort different types of plastic waste automatically. These machines utilize advanced sensors and artificial intelligence to recognize and separate different types of plastics based on their chemical composition and physical properties. This automated sorting process eliminates the need for manual sorting and significantly reduces human error, resulting in higher efficiency and accuracy. Once sorted, the plastics are then shredded into smaller pieces, making them ready for the pelletizing process.

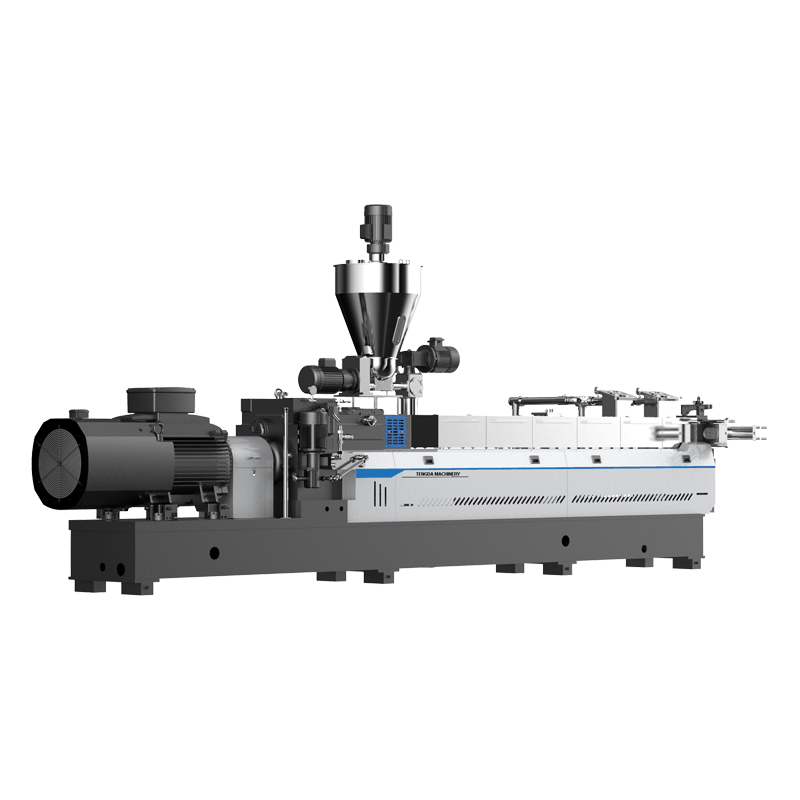

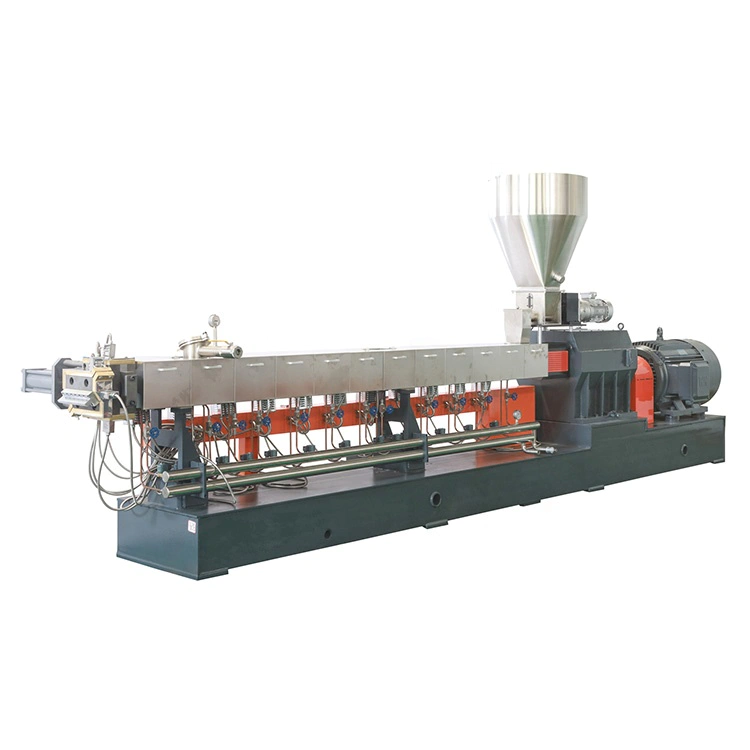

2. Enhanced Pelletizing Capability:

Compared to traditional recycling methods, next-gen recycling pelletizing machines offer enhanced pelletizing capability. These machines are designed to handle a wide range of plastic waste, including both rigid and flexible plastics. The advanced extrusion systems in these machines ensure high-quality pellets are produced consistently. The pellets produced by these machines have a uniform shape, size, and density, making them suitable for a variety of applications.

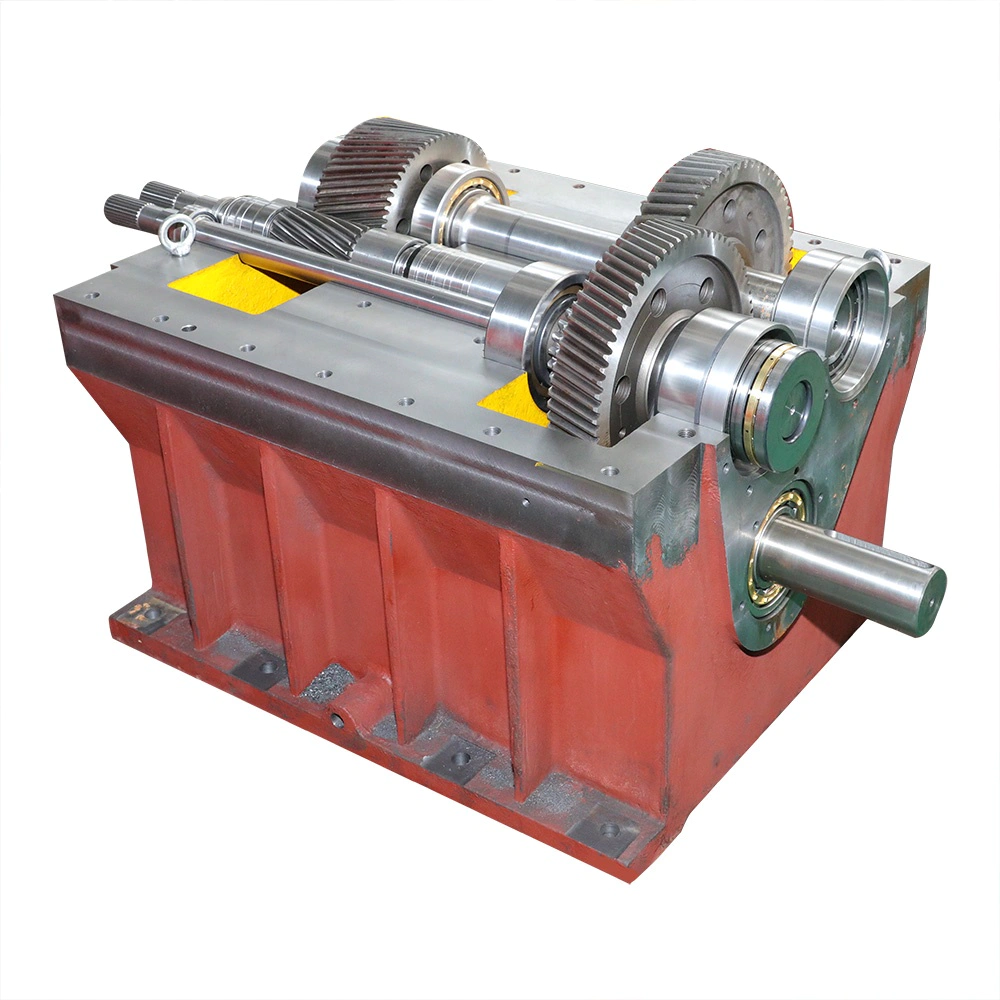

3. Energy Efficiency and Conservation:

Next-gen solutions prioritize energy efficiency and conservation, ensuring that the recycling process itself remains sustainable. These machines incorporate energy-saving technologies such as advanced heat recovery systems, efficient motor systems, and optimized processing parameters. By minimizing energy consumption during the recycling process, these machines not only reduce operational costs but also contribute to a greener and more sustainable future.

4. Customizability and Adaptability:

Next-gen waste plastic recycling pelletizing machines offer a high degree of customizability and adaptability to meet the specific needs of different industries. These machines can be tailored to process various types of plastic waste and produce pellets with specific characteristics. Whether it's color, size, or composition, these machines can be fine-tuned to produce pellets that meet the exact requirements of end-users. This versatility allows for a wider range of applications for the recycled plastic pellets, making them highly sought after in industries such as packaging, automotive, construction, and more.

5. Improved Safety and Operational Efficiency:

Next-gen solutions prioritize safety and operational efficiency to ensure a seamless recycling process. These machines are equipped with advanced safety features such as automatic shutdown mechanisms, emergency stop buttons, and real-time monitoring systems to prevent accidents and ensure the well-being of operators. Additionally, the user-friendly interfaces and intuitive controls of these machines make them easy to operate and maintain, minimizing downtime and maximizing productivity.

Conclusion:

Next-gen waste plastic recycling pelletizing machines offer a ray of hope in the battle against plastic pollution. With their advanced sorting, shredding, and pelletizing capabilities, these machines have the power to transform plastic waste into valuable resources while minimizing environmental impact. The customizability, energy efficiency, and improved safety features make them an attractive solution for industries seeking sustainable alternatives to virgin plastic. As we continue to tackle the global plastic waste crisis, it is crucial to embrace innovations like these next-gen solutions, driving us closer to a greener and more sustainable future.