Optimizing Production with an Advanced ABS Sheet Extrusion Line

Article:

Optimizing Production with an Advanced ABS Sheet Extrusion Line

Introduction:

In today's fast-paced manufacturing industry, efficiency and quality are paramount. As a result, companies are constantly seeking innovative solutions to optimize their production processes. One remarkable advancement in the realm of extrusion technology is the development of an Advanced ABS Sheet Extrusion Line. This cutting-edge system promises to revolutionize the manufacturing landscape by offering increased productivity, enhanced product quality, and reduced operational costs. In this article, we delve into the various aspects of this advanced extrusion line and explore its profound impact on production optimization.

1. The Significance of ABS Sheet Extrusion:

ABS, or Acrylonitrile Butadiene Styrene, is a commonly used thermoplastic polymer known for its exceptional toughness and impact resistance. It finds numerous applications in industries such as automotive, construction, electrical, and consumer goods. ABS sheets are versatile and can be easily molded into intricate shapes, offering immense design freedom to manufacturers. Therefore, optimizing the production of ABS sheets has significant implications for a wide range of industries.

2. Understanding the Advanced ABS Sheet Extrusion Line:

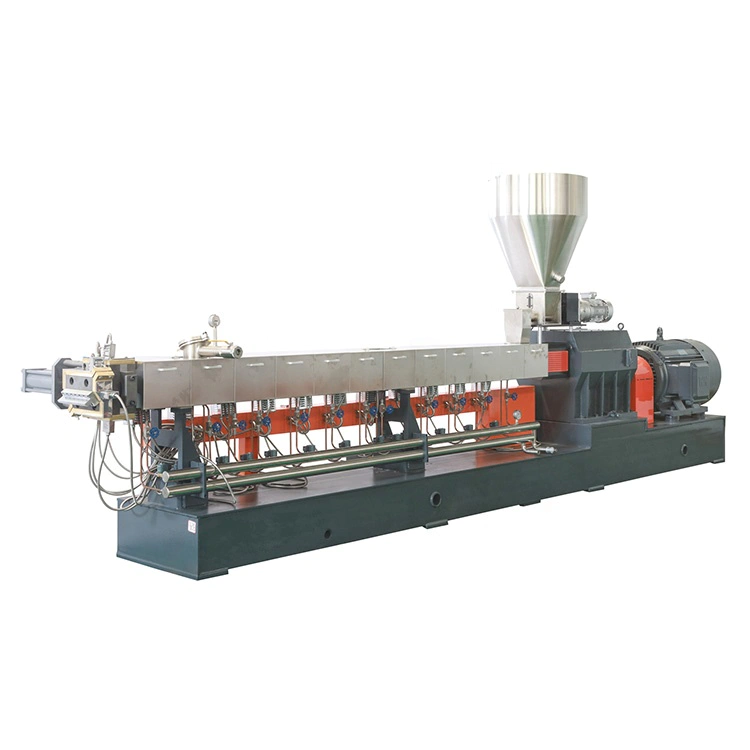

The Advanced ABS Sheet Extrusion Line represents a state-of-the-art technology that maximizes production efficiency while ensuring optimum product quality. This automated system integrates various innovative features that streamline the extrusion process from start to finish. Let us explore some key elements of this advanced extrusion line:

2.1 High-precision Control Systems:

The advanced ABS extrusion line incorporates cutting-edge control systems that allow for precise monitoring and adjustment of critical parameters. This level of control ensures consistency in product dimensions, mechanical properties, and material distribution, leading to high-quality ABS sheets.

2.2 Intelligent Heating and Cooling Mechanisms:

Temperature control is paramount during the extrusion process as it directly impacts the material's flow behavior and final product properties. The advanced ABS sheet extrusion line utilizes intelligent heating and cooling mechanisms to achieve precise temperature control throughout the extruder. This optimized process results in improved melt homogeneity and reduced internal stresses in the ABS sheets.

2.3 Integrated Quality Measurement:

To ensure product quality at every step, the advanced ABS sheet extrusion line incorporates built-in quality measurement systems. These systems employ advanced sensors and software algorithms to monitor key parameters such as sheet thickness, surface smoothness, and material consistency. In case of any deviations, the system can automatically make real-time adjustments to maintain consistent product quality.

3. Advantages of the Advanced ABS Sheet Extrusion Line:

Implementing the advanced ABS sheet extrusion line offers several advantages that contribute to overall production optimization. Here are some notable benefits:

3.1 Increased Production Output:

Thanks to its automated and highly efficient design, the advanced ABS sheet extrusion line enables manufacturers to substantially increase production output. The precise control systems and optimized process parameters allow for faster extrusion rates without compromising product quality. As a result, manufacturers can meet growing market demands and maximize their revenue potential.

3.2 Enhanced Product Quality:

Consistency and uniformity are crucial for producing high-quality ABS sheets. The advanced extrusion line's intelligent control systems and quality measurement capabilities ensure that every ABS sheet maintains the desired properties throughout the production process. Such enhanced product quality strengthens customer satisfaction and helps manufacturers maintain a competitive edge.

3.3 Reduced Energy Consumption:

In today's environmentally conscious world, energy efficiency has become a key performance metric for industrial processes. The advanced ABS sheet extrusion line incorporates energy-saving components and optimized process parameters to minimize energy consumption. This not only reduces operational costs but also demonstrates a commitment to sustainability.

3.4 Streamlined Maintenance and Troubleshooting:

The advanced ABS sheet extrusion line features comprehensive diagnostic tools and remote monitoring capabilities that simplify maintenance and troubleshooting. The system can detect potential issues in real-time, allowing for timely interventions and preventing costly production downtime. With easy access to detailed performance data, manufacturers can proactively address any maintenance needs, thereby maximizing production uptime.

3.5 Increased Flexibility and Adaptability:

The advanced ABS sheet extrusion line is designed to accommodate various sheet thicknesses and widths, enabling manufacturers to meet the diverse needs of their customers. Quick changeover times and adjustable settings allow for seamless transitions between different production runs. This flexibility empowers manufacturers to adapt swiftly to market changes and fulfill customized orders promptly.

4. Industry Applications and Future Possibilities:

The advanced ABS sheet extrusion line offers immense potential for numerous industries reliant on ABS sheets. Automotive manufacturers can benefit from the production of high-quality ABS sheets for interior components, exterior trims, and structural parts. In the construction sector, the extrusion line can meet the demand for superior ABS sheets for applications such as wall cladding, roofing, and window frames. Additionally, the consumer goods industry can utilize the line to produce customized ABS sheets for electronics, home appliances, and various other consumer products.

Looking ahead, the advanced ABS sheet extrusion line holds promise for further advancements in terms of higher production speeds, integration with industry 4.0 technologies for enhanced automation, and the development of eco-friendly materials. With ongoing research and development, this technology will continue to evolve, redefine production optimization, and push the boundaries of what is achievable in ABS sheet extrusion.

Conclusion:

The introduction of the Advanced ABS Sheet Extrusion Line is a game-changer for manufacturers seeking to optimize production processes. By combining high-precision control systems, intelligent heating and cooling mechanisms, and integrated quality measurement, this advanced technology significantly enhances efficiency, quality, and adaptability. The advantages of increased production output, enhanced product quality, reduced energy consumption, streamlined maintenance, and increased flexibility make this extrusion line invaluable in various industries. As the field of ABS sheet extrusion continues to progress, the future possibilities for this advanced technology are vast, positioning it as a crucial component of modern manufacturing.

At a time when technology is essential for Application, ensuring that it works in a symbiotic way with your human employees is key.

See reviews of the latest trend in Application industry at TENGDA Extruder Machine Manufacturers, and see the best that work in just minutes! Visit us right away!

To properly understand what customers want, when, why and how they want it, Nanjing Tengda Machinery Co., Ltd. needs to pivot toward sentiment analysis, a burgeoning technology that taps into consumer demand based on natural language processing.

The plastic extruder machine manufacturers-type Application is poised to lead the extruder machine manufacturers market.

There's the area of manufacturing Application that's becoming very important. If you can create those things, you build this closed bond.