Optimizing Your Production Process with a High-Quality Sheet Extrusion Line

In the manufacturing industry, optimizing the production process is crucial for businesses looking to enhance their efficiency and output. One key aspect of this optimization lies in investing in high-quality equipment such as a sheet extrusion line. A sheet extrusion line is a versatile and indispensable tool for various industries, enabling the production of high-quality sheets for a wide range of applications. In this article, we will explore the importance of optimizing production processes through the use of a high-quality sheet extrusion line and discuss its benefits and applications.

I. Understanding the Sheet Extrusion Process

II. Benefits of Investing in a High-Quality Sheet Extrusion Line

III. Enhanced Efficiency and Increased Output

IV. Consistent and Uniform Sheet Quality

V. Versatility and Adaptability to Different Materials

VI. Diverse Applications and End Products

VII. Choosing the Right Sheet Extrusion Line for Your Business

VIII. Important Considerations Before Purchasing a Sheet Extrusion Line

IX. Maintenance and Care for Prolonged Lifespan

X. Conclusion

I. Understanding the Sheet Extrusion Process

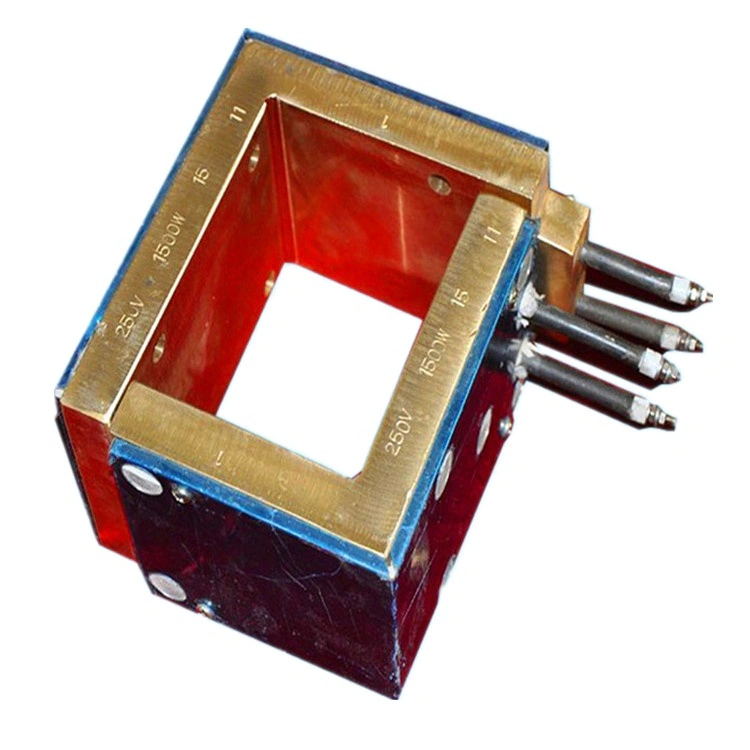

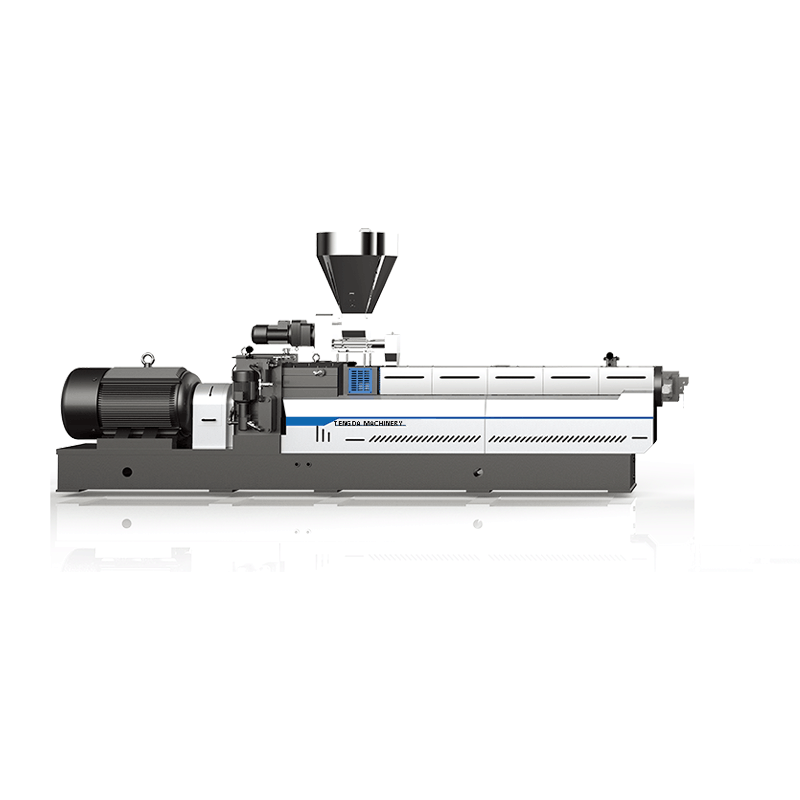

The sheet extrusion process involves the conversion of raw materials such as plastic resins into flat sheets of various thicknesses and widths. A high-quality sheet extrusion line consists of several components, including an extruder, a die, a cooling system, and winding equipment. The raw material is fed into the extruder, where it is melted, homogenized, and pushed through a carefully designed die. The extruded molten material is then cooled and solidified into a flat sheet before being wound onto a roll. This continuous process allows for the efficient production of consistent and high-quality sheets.

II. Benefits of Investing in a High-Quality Sheet Extrusion Line

1. Enhanced Efficiency and Increased Output

One of the primary advantages of utilizing a high-quality sheet extrusion line is the improvement in production efficiency. Advanced features such as automated controls, precision temperature regulation, and optimized design reduce downtime, minimize material wastage, and increase productivity. By streamlining the extrusion process, businesses can achieve faster turnaround times, meet deadlines, and fulfill customer demands promptly. Ultimately, this translates into higher profits and a competitive edge in the industry.

2. Consistent and Uniform Sheet Quality

A key aspect of any manufacturing process is maintaining consistent product quality. With a high-quality sheet extrusion line, businesses can ensure that the produced sheets exhibit uniform properties, such as thickness, width, and surface quality. The advanced controls and monitoring systems of these extrusion lines allow for precise adjustments, resulting in consistent output throughout the production run. Consistent sheet quality is crucial for industries like packaging, construction, and automotive, where specific standards must be met.

3. Versatility and Adaptability to Different Materials

Investing in a high-quality sheet extrusion line grants businesses the flexibility to work with a wide range of materials. These extrusion lines can process various thermoplastic resins, such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polystyrene (PS), among others. Each material possesses unique characteristics and applications, and the ability to process multiple materials expands the business's capabilities and potential customer base.

4. Diverse Applications and End Products

The applications of sheets produced using a sheet extrusion line are abundant. These sheets can be used in various industries, including packaging, construction, automotive, electronics, and agriculture. In the packaging industry, sheets can be transformed into containers, trays, blister packs, and more. For construction purposes, sheets can be used in roofing, insulation, and flooring applications. The automotive industry utilizes sheets for interior components, instrument panels, and exterior trim. The versatility of sheets opens up a plethora of opportunities for businesses across different sectors.

5. Choosing the Right Sheet Extrusion Line for Your Business

When considering the purchase of a sheet extrusion line, several factors need to be taken into account. These include the required sheet size, the desired output capacity, the materials to be processed, and budgetary considerations. Consulting with industry experts and reputable manufacturers is crucial to ensure that the chosen sheet extrusion line meets specific business needs and goals. In addition, evaluating the durability, reliability, and energy efficiency of the equipment is essential for long-term success and return on investment.

III. Important Considerations Before Purchasing a Sheet Extrusion Line

Before finalizing the purchase of a sheet extrusion line, businesses should thoroughly assess their requirements and consider the following:

1. Capacity and Throughput: Determine the desired production capacity based on market demand and growth projections. Consider factors like the extruder's output rate, cooling and winding speeds, and the overall line speed.

2. Material Compatibility: Identify the specific types of materials the business intends to process and ensure that the chosen sheet extrusion line is compatible with those materials. Different materials may require specific extruder configurations, die shapes, and temperature controls.

3. Customization Options: Look for manufacturers that offer customization options to tailor the sheet extrusion line to the business's unique requirements. This can include specialized die designs, sheet thickness control systems, or auxiliary equipment integration.

4. Energy Efficiency: Opt for energy-efficient extrusion lines to reduce operational costs and minimize environmental impact. Look for features like efficient heat exchange systems, advanced motor controls, and energy recovery mechanisms.

5. After-Sales Support and Maintenance: Ensure that the manufacturer provides comprehensive after-sales support, including maintenance, troubleshooting, and spare parts availability. Regular maintenance and timely repairs are crucial for maximizing the lifespan and performance of the sheet extrusion line.

IV. Maintenance and Care for Prolonged Lifespan

To maximize the lifespan and efficiency of a sheet extrusion line, businesses should implement regular maintenance protocols. Some essential maintenance tasks include:

1. Daily Cleaning: Properly clean the extruder, die, and related components to remove any residue or build-up that could affect the quality of the sheets and cause operational issues.

2. Routine Lubrication: Apply lubricants to various mechanical components at regular intervals to reduce friction, wear, and tear.

3. Temperature Calibration: Periodically calibrate the temperature control systems to ensure accurate and consistent temperature regulation throughout the extrusion process.

4. Inspection and Component Replacement: Regularly inspect components such as screws, heaters, sensors, and screens for signs of wear and damage. Replace any worn-out or malfunctioning parts before they cause significant disruptions.

5. Operator Training: Provide comprehensive training to operators on the operation, maintenance, and troubleshooting of the sheet extrusion line. Well-trained operators can detect potential issues early and perform basic repairs, minimizing downtime.

V. Conclusion

Investing in a high-quality sheet extrusion line is a wise move for businesses looking to optimize their production processes. The benefits of enhanced efficiency, increased output, consistent sheet quality, versatility, and diverse applications make these extrusion lines indispensable in various manufacturing sectors. By carefully assessing specific business requirements and selecting the right equipment, businesses can elevate their production capabilities, meet customer demands, and achieve sustainable growth in an increasingly competitive marketplace.

Nanjing Tengda Machinery Co., Ltd. has various branches in different countries worldwide.

You can count on Nanjing Tengda Machinery Co., Ltd. to be your one stop shopping site for most of the quality products you are searching for. We strive to offer a wide variety of products for you to learn about and to purchase.

Application is one of the best products sold in the market today.

Nanjing Tengda Machinery Co., Ltd. provides a way for you to understand your customers, to learn what makes them unique and what motivates their behavior. We can then leverage that wealth of information to personalize our interactions and demonstrate that Application is valuable to our customers.