PET Bottle Extruder: A Sustainable Packaging Solution for the Beverage Industry

Advancements in Packaging: PET Bottle Extruder

The beverage industry is constantly evolving, and with it, the need for sustainable packaging solutions has become more crucial than ever. In recent years, there has been a growing focus on reducing plastic waste and embracing eco-friendly alternatives. One such solution that has gained significant traction is the PET bottle extruder. This innovative technology offers a sustainable packaging solution that not only meets the demands of the beverage industry but also addresses environmental concerns.

Understanding PET Bottle Extruder

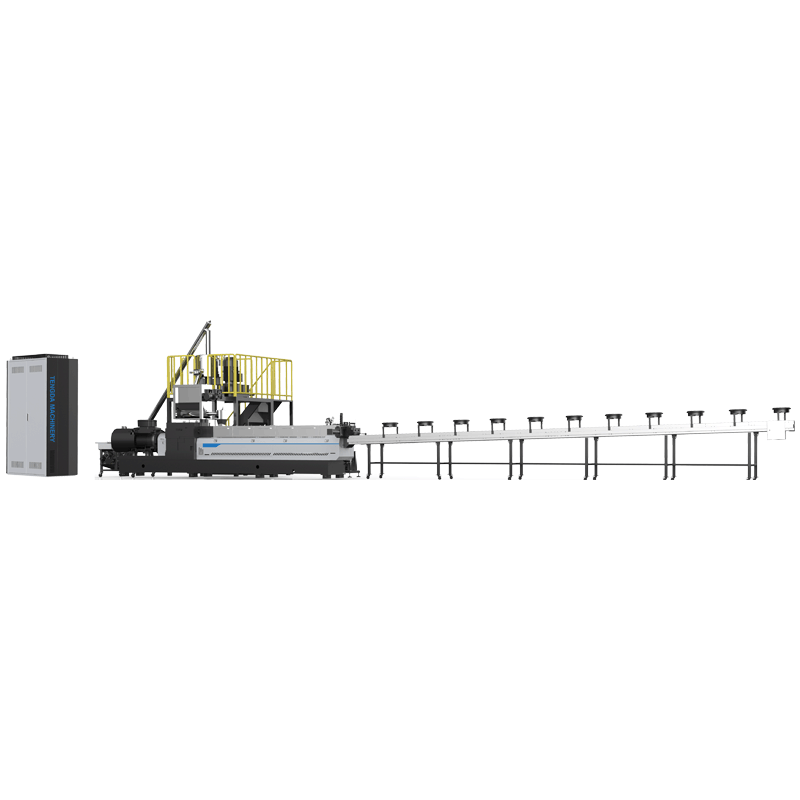

PET, or Polyethylene Terephthalate, is a highly versatile plastic widely used in the packaging industry. PET bottles are commonly used for the packaging of beverages such as water, soda, juices, and more. A PET bottle extruder is a machine that takes raw PET materials and transforms them into the familiar plastic bottles we see on store shelves.

The extrusion process involves melting the PET resin and then pumping it through a die, which gives the plastic its desired shape and size. The molten plastic is then cooled, solidified, and cut into individual bottles. This process allows for the production of high-quality, uniform bottles with minimal material waste.

The Benefits of PET Bottle Extruder in the Beverage Industry

1. Reduced Environmental Impact: One of the primary advantages of PET bottle extruders is their positive impact on the environment. PET is a highly recyclable material, and using it in the manufacturing process significantly reduces plastic waste. Furthermore, PET bottles have a lower carbon footprint compared to alternatives such as glass or aluminum.

2. Lightweight: PET bottles are incredibly lightweight, making them easy to transport and handle. This characteristic is particularly important in the beverage industry, where packaging weight directly affects transportation costs and fuel consumption. By utilizing PET bottle extruders, beverage companies can minimize their ecological footprint and reduce their overall logistics expenses.

3. Resistance to Breakage: PET bottles are known for their durability and resistance to breakage. Unlike glass containers, PET bottles are less prone to shattering, making them safer to use in various settings, including outdoor events, picnics, and sporting activities. Additionally, their resilience helps prevent product loss during transportation, ensuring that beverages reach consumers in optimal condition.

4. Versatility: PET bottle extruders offer unparalleled design flexibility, allowing manufacturers to create bottles in a wide range of shapes and sizes. This versatility enables companies to create unique packaging designs that can enhance brand recognition and customer appeal. From ergonomically shaped bottles for enhanced grip to innovative cap designs for improved functionality, PET bottle extruders offer endless possibilities for beverage packaging.

5. Cost-Effectiveness: PET bottle extruders provide a cost-effective solution for beverage packaging. The extrusion process allows for high-speed production, resulting in lower manufacturing costs per bottle. Additionally, the lightweight nature of PET bottles reduces transportation costs, making them an economically viable option for beverage manufacturers.

Challenges and Future Prospects

While PET bottle extruders offer numerous advantages, there are challenges that need to be addressed to further enhance their sustainability. One significant concern is the recycling and disposal of PET bottles. Despite being recyclable, not all PET bottles end up in recycling facilities. Increased awareness and robust recycling infrastructure are essential to ensure proper disposal and reduce plastic waste.

The future prospects for PET bottle extruders are promising. Researchers and manufacturers are constantly striving to develop more efficient and environmentally friendly extrusion technologies. This includes exploring alternative materials, improving energy efficiency, and reducing water usage in the manufacturing process. Continuous innovation and collaboration within the industry will play a pivotal role in driving the adoption of PET bottle extruders and furthering the sustainability agenda.

Conclusion

The beverage industry is embracing sustainable packaging solutions, and PET bottle extruders offer a compelling option. With reduced environmental impact, versatility, and cost-effectiveness, PET bottles provide beverage manufacturers with an eco-friendly alternative without compromising quality or design. However, to maximize the benefits of PET bottle extruders, it is crucial to strengthen recycling practices and promote responsible plastic waste management. By investing in technological advancements and sustainable practices, the beverage industry can make significant strides towards a greener and more sustainable future.

Application has become a standardized way of dealing with extruder machine manufacturers.

At the heart of Application is our Vision to be the global energy company most admired for its people, partnership and performance.

In various different types of plastic extruder machine manufacturers, extruder machine manufacturers Application is one of the most commonly used.