PET Bottle Extruder: The Benefits of Blowing Your Own Bottles In-House

The Benefits of Blowing Your Own Bottles In-House

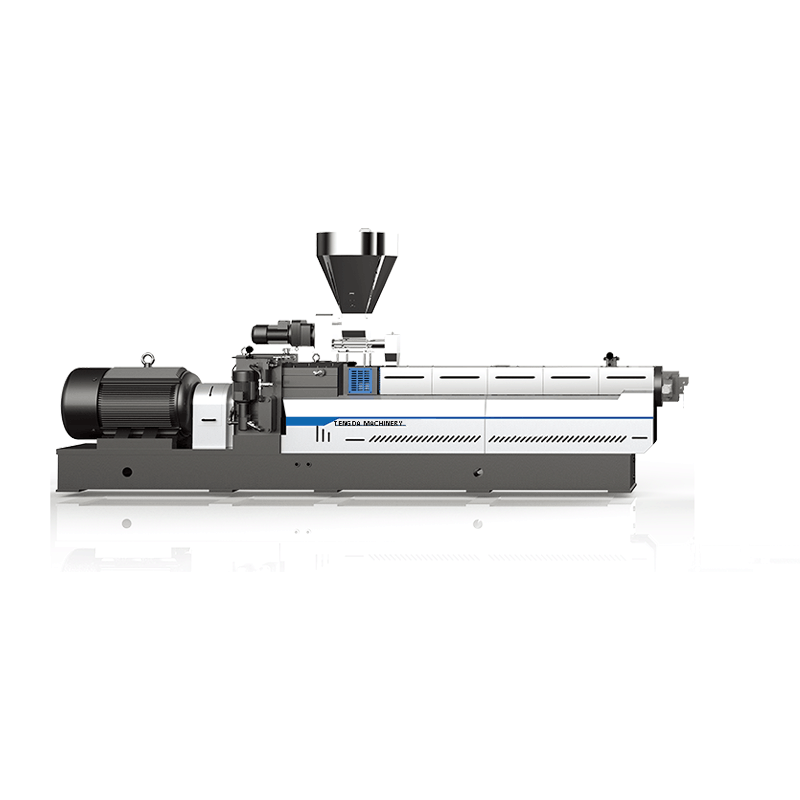

In today's fast-paced consumer market, it has become increasingly important for businesses to find new ways to reduce costs and increase efficiency. One such way is by investing in a PET bottle extruder, a machine that allows companies to blow their own bottles in-house. This article will explore the numerous benefits of adopting this technology, from cost savings to increased quality control.

Improved Cost Efficiency and Flexibility

By investing in a PET bottle extruder, businesses can significantly reduce their production costs in several ways. Firstly, outsourcing the manufacturing of bottles can be expensive, as it involves additional transportation costs and markups from third-party suppliers. Bringing the production in-house eliminates these costs and allows companies to have better control over their supply chain.

Moreover, using a PET bottle extruder offers greater flexibility in terms of bottle design and customization. When relying on external suppliers, businesses often have limited options for bottle shapes, sizes, and colors. This lack of flexibility can hinder branding efforts and leave companies at a disadvantage. However, with an in-house extruder, businesses have the freedom to experiment with different designs, enabling them to create unique and eye-catching bottles that align with their brand identity.

Enhanced Quality Control

By blowing their own bottles in-house, businesses gain full control over the quality of their products. External suppliers may not always meet the desired quality standards, resulting in defective or damaged bottles. This can lead to various issues such as leakage, breakage, or weakened structural integrity, which in turn affects customer satisfaction and product integrity.

With a PET bottle extruder, manufacturers can closely monitor all stages of the production process, ensuring that each bottle meets strict quality criteria. They can control variables such as material selection, wall thickness, and overall structural integrity. This not only enhances product quality but also reduces the need for returns or replacements, saving both time and money.

Reduced Environmental Impact

In recent years, the need for sustainable business practices has become increasingly apparent. Consumers are becoming more conscious of the environmental impact of their purchasing decisions, and businesses must adapt accordingly. Adopting an in-house PET bottle extruder can contribute to a company's sustainability efforts in several ways.

Firstly, by eliminating the need for external suppliers, businesses can significantly reduce their carbon footprint associated with transportation. This, in turn, reduces emissions and helps combat climate change. Additionally, by using their own extruder, companies have better control over the materials used in the production process. This allows them to explore more eco-friendly options, such as using recycled PET or incorporating biodegradable additives, further reducing their environmental impact.

Increased Production Speed

In the fast-paced consumer market, speed is of the essence. Businesses need to deliver products quickly to meet customer demands and stay ahead of the competition. Outsourcing bottle production often introduces delays, as companies must rely on the schedules and capacities of external suppliers. These delays can have a significant impact on a company's overall production timeline.

By blowing their own bottles in-house, businesses can streamline their production process and improve overall efficiency. With a PET bottle extruder, bottles can be produced on-demand, eliminating the need to wait for deliveries or deal with supply chain disruptions. This increased production speed allows businesses to respond quickly to market trends and maintain a competitive edge.

Maximized Product Customization

Product differentiation is crucial in today's crowded consumer market. By blowing their own bottles in-house, businesses can fully customize their products to meet customer preferences and stand out from competitors. This level of customization goes beyond bottle design and can include factors such as color, labeling, and even embossing or printing special features on the bottles.

Furthermore, an in-house PET bottle extruder enables companies to respond rapidly to changing market demands and consumer preferences. By leveraging their flexibility, businesses can quickly adapt their bottle designs to incorporate new trends, promotions, or seasonal variations. This level of agility ensures that companies remain relevant and can meet the ever-evolving needs and expectations of their customers.

Summary

Investing in a PET bottle extruder offers numerous benefits for businesses across various industries. From improved cost efficiency and flexibility to enhanced quality control, the advantages of blowing your own bottles in-house are undeniable. By reducing costs, optimizing production processes, and maximizing customization capabilities, businesses can gain a competitive edge, enhance sustainability efforts, and ensure customer satisfaction. As the consumer market continues to evolve, adopting this technology has become a strategic decision that can propel businesses forward in their respective industries.