PET Bottle Extruder: The Benefits of Lightweight and Durable PET Packaging

The Benefits of Lightweight and Durable PET Packaging

Introduction:

The packaging industry has witnessed a significant shift towards eco-friendly solutions in recent years. As environmental concerns continue to grow, businesses are seeking alternatives that reduce their carbon footprint while maintaining the quality and functionality of their products. One such solution that has gained immense popularity is the PET bottle extruder. This revolutionary technology enables the production of lightweight and durable PET packaging, offering numerous advantages over traditional packaging materials. In this article, we will explore the benefits of lightweight and durable PET packaging and how it is transforming the packaging industry.

Enhancing Sustainability with Lightweight PET Packaging

PET (Polyethylene Terephthalate) is a widely used thermoplastic polymer that has become a popular choice for packaging materials due to its excellent properties. One of the most significant advantages of lightweight PET packaging is its positive impact on sustainability. By using less material, PET bottles contribute to the reduction of energy consumption, greenhouse gas emissions, and waste generation during production and transportation compared to traditional packaging options.

A key factor that enables PET bottles to be lightweight is their high strength-to-weight ratio. PET is naturally strong and rigid, making it an ideal choice for packaging applications. This inherent strength allows manufacturers to reduce the amount of plastic used while still ensuring the integrity of the packaging. The lightweight nature of PET bottles also translates to reduced fuel consumption during transportation, further reducing carbon emissions.

Additionally, lightweight PET packaging can lead to a reduction in food waste. The durability of PET materials helps protect the contents from damage during handling and transportation, ensuring that the product reaches consumers in optimal condition. Moreover, PET packaging is resistant to water and oxygen, effectively preserving the freshness and extending the shelf life of perishable goods. By minimizing the risk of spoilage, lightweight PET packaging plays a vital role in minimizing food waste, a growing concern in today's world.

Durability and Its Added Benefits

In addition to being lightweight, PET packaging offers exceptional durability, making it an ideal choice for various industries. The durability of PET bottles provides several advantages in terms of product protection, consumer convenience, and cost-efficiency.

PET bottles are highly resistant to impact, which significantly reduces the risk of breakage during storage, transportation, and handling. This characteristic is particularly valuable in the beverage industry, where bottles are often subjected to rigorous conditions. By withstanding impacts, PET packaging ensures that products remain intact and that any potential leaks or spills are minimized.

Moreover, the durability of PET packaging enhances consumer convenience. PET bottles often come with resealable caps or lids that allow consumers to keep the product fresh after opening. This feature is especially crucial for beverages or products that are consumed over time, eliminating the need for separate storage containers or wasting the contents.

Another benefit of PET's durability is its resistance to temperature variations. PET bottles can withstand a wide range of temperatures, making them suitable for both hot and cold products. This versatility makes PET packaging an excellent choice for a variety of beverages, including both carbonated and non-carbonated drinks.

From a business perspective, the durability of PET packaging can result in significant cost savings. With its strength and resistance to breakage, PET bottles require fewer replacements due to damage during transportation or handling. This reduction in product loss leads to cost efficiencies and overall lower operational expenses for businesses.

Advancing Design Capabilities for PET Packaging

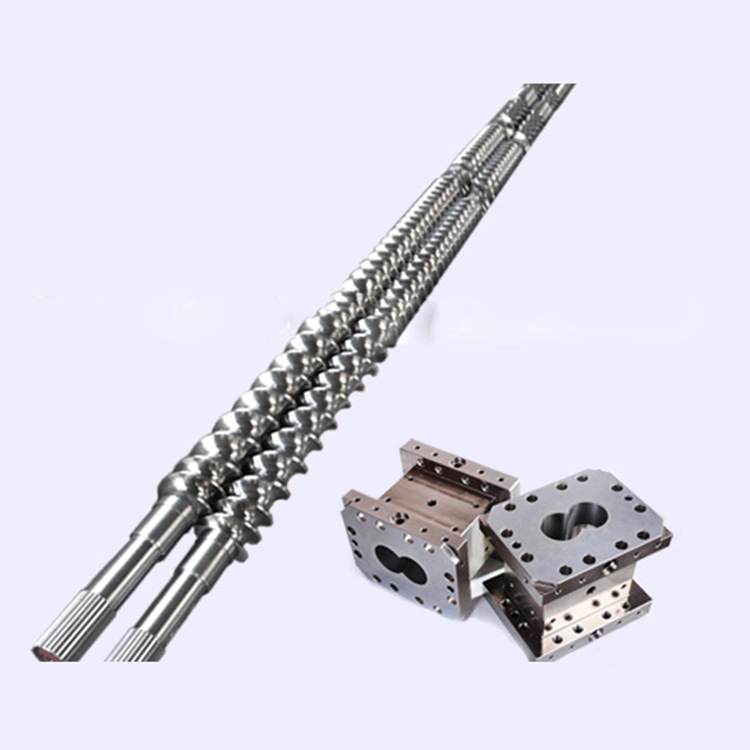

With advancements in manufacturing technology, lightweight and durable PET packaging has expanded its design capabilities, providing businesses with greater flexibility and creativity in their packaging solutions. The PET bottle extruder, in particular, has played a crucial role in pushing the boundaries of design possibilities.

The extrusion process allows for the creation of complex shapes and unique features that were previously challenging to achieve with traditional packaging materials. PET bottles can now be designed with different neck finishes, grips, and embossing to enhance ergonomics, aesthetics, and branding opportunities. This flexibility enables businesses to differentiate their products on the store shelves, capture consumer attention, and strengthen brand identity.

Additionally, PET packaging can be produced in various sizes and volumes, accommodating different product requirements. From small single-serve bottles to larger containers, businesses can choose the most appropriate size for their product offerings. The ability to customize the shape, size, and design of PET packaging provides businesses with a competitive edge, allowing them to meet consumer demands and preferences effectively.

The Recyclability of PET Packaging

Another essential aspect of PET packaging is its recyclability. PET is one of the most recycled plastics worldwide, emphasizing its contribution to a circular economy. Recycling PET bottles conserves energy, reduces the consumption of raw materials, and lowers waste generation.

The recycling process for PET packaging involves several stages. First, the bottles are collected and sorted based on their resin type. They are then cleaned, shredded, and processed into small flakes. These flakes are melted to form new PET resin, which can be used to produce various products, including new bottles.

The high recyclability of PET ensures that it can be transformed into new packaging materials multiple times, reducing reliance on virgin plastics. As efforts to promote recycling and sustainability continue to gain momentum, the demand for recycled PET, known as rPET, is expected to increase. By investing in lightweight and durable PET packaging, businesses contribute to the circular economy and promote a greener future.

Conclusion

Lightweight and durable PET packaging offers numerous benefits that align with the growing demand for sustainable packaging solutions. The exceptional strength-to-weight ratio of PET bottles contributes to reduced energy consumption, minimized carbon emissions, and a decrease in waste generation. Furthermore, the durability of PET packaging enhances product protection, consumer convenience, and cost-efficiency. With advancements in manufacturing technology and design capabilities, businesses can tap into the versatility of PET packaging to differentiate their products and strengthen their brand presence. The recyclability of PET packaging further reinforces its position as an eco-friendly choice. As the packaging industry continues to evolve, lightweight and durable PET packaging will undoubtedly play a pivotal role in meeting both consumer and environmental needs.