PET Extrusion Line: Improving Production Efficiency and Output

PET Extrusion Line: Improving Production Efficiency and Output

Introduction

In today's competitive market, manufacturers are constantly seeking innovative solutions to improve production efficiency and output. One such solution gaining popularity is the PET extrusion line. This cutting-edge technology is revolutionizing the way plastic products are manufactured. By utilizing advanced machinery and processes, the PET extrusion line offers several benefits that can significantly enhance productivity and output. In this article, we will delve into the intricacies of the PET extrusion line and explore its various advantages.

1. The Basics of PET Extrusion

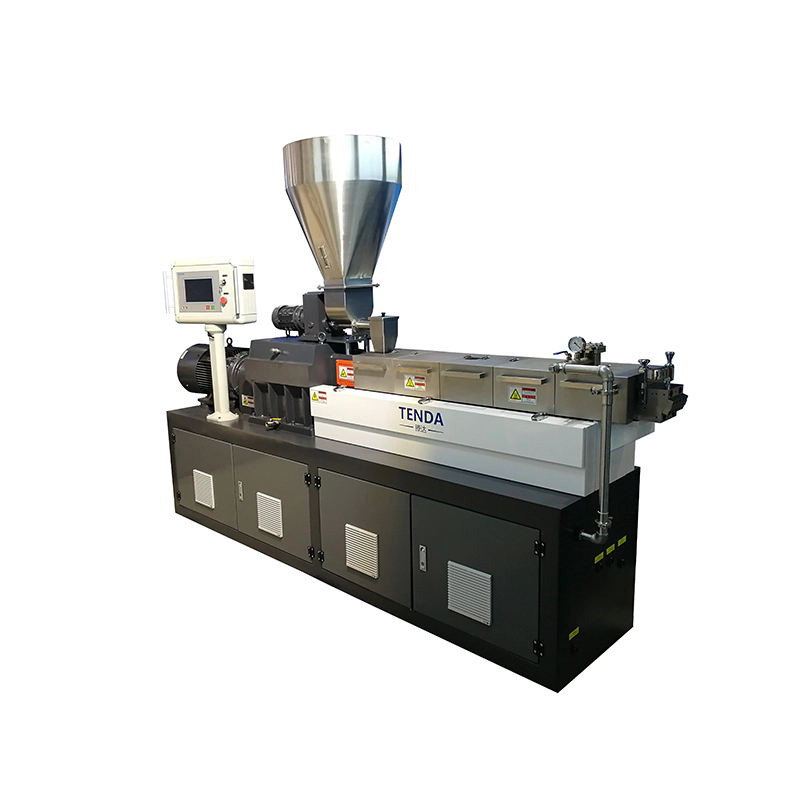

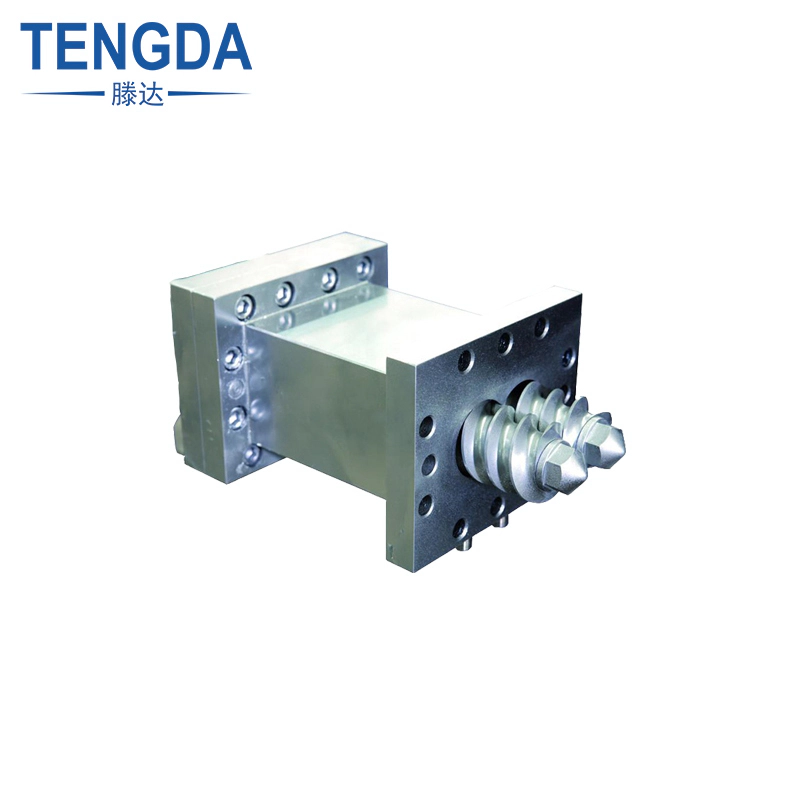

PET (Polyethylene Terephthalate) is a high-performance plastic used in the production of various products such as bottles, containers, and packaging materials. PET extrusion involves the process of transforming raw PET resin into a continuous profile with a desired shape and cross-section. The extrusion line consists of several components, including a hopper for resin feeding, a heating system to melt the PET, a screw extruder to generate the required pressure for the process, a die for shaping the profile, and a cooling system to solidify the extruded material.

2. Enhanced Efficiency through Automation

One of the significant advantages of the PET extrusion line is its ability to automate the entire production process. Automation eliminates the need for manual intervention, reducing the chances of human errors and ensuring consistent quality. With automated controls, manufacturers can precisely regulate parameters such as temperature, pressure, and speed, resulting in a more streamlined operation. This level of precision allows for higher production rates and improved product quality.

3. Minimized Downtime and Increased Uptime

Downtime can be a major hindrance to any manufacturing process. The PET extrusion line tackles this issue by minimizing downtime and maximizing uptime through various mechanisms. For instance, automatic material changeovers allow for quick and seamless transitions between different PET resins, significantly reducing production interruptions. Additionally, advanced sensors and monitoring systems enable early detection of potential issues, allowing for preventive maintenance. By proactively addressing problems, manufacturers can ensure smooth operations and enhanced productivity.

4. Improved Energy Efficiency

Energy consumption is a significant concern in the manufacturing industry. The PET extrusion line incorporates energy-efficient technologies to reduce overall power consumption. Advanced heating systems utilize precise temperature control mechanisms, optimizing the energy required for melting the PET resin. Furthermore, intelligent cooling systems are designed to minimize energy wastage by efficiently cooling the extruded material. These energy-saving features not only contribute to a greener environment but also result in substantial cost savings for manufacturers.

5. Flexibility and Versatility

The PET extrusion line offers unparalleled flexibility and versatility in product design and manufacturing. The extrusion process allows for the creation of complex shapes and profiles with high precision. Manufacturers can easily adjust the die and screw configurations to produce a wide range of PET products, catering to diverse market demands. This flexibility enables businesses to stay competitive and adapt to changing customer preferences quickly.

6. Enhanced Output and Productivity

With increased line speeds and optimized processing parameters, the PET extrusion line boosts production output and overall productivity. The ability to operate at higher speeds while maintaining quality standards allows manufacturers to meet growing market demands efficiently. Additionally, the advanced cooling systems significantly reduce the cooling time of the extruded material, enabling faster production cycles. By focusing on improving output and productivity, businesses can realize higher profitability and gain a competitive edge.

7. Quality Assurance and Consistency

Maintaining consistent product quality is imperative for any manufacturer. The PET extrusion line guarantees superior quality and consistency through its automated control systems. With precise control over parameters, including temperature, pressure, and cooling, manufacturers can ensure consistent product dimensions and properties. This level of quality assurance enhances customer satisfaction and builds a strong reputation for the brand.

8. Waste Reduction and Cost Savings

Effective waste management is essential for sustainable manufacturing. The PET extrusion line minimizes material wastage through efficient control of the entire extrusion process. By accurately controlling the melt flow and cooling parameters, manufacturers can reduce scrap and rework, resulting in significant cost savings. Moreover, the ability to incorporate recycled PET materials into the extrusion process further enhances sustainability while optimizing costs.

Conclusion

In conclusion, the PET extrusion line is revolutionizing the manufacturing industry by improving production efficiency and output. Its automated processes, minimized downtime, enhanced energy efficiency, flexibility, and increased productivity make it an ideal choice for manufacturers seeking to stay competitive in today's fast-paced market. Moreover, by ensuring consistent quality, reducing waste, and optimizing costs, the PET extrusion line contributes to sustainable and environmentally friendly manufacturing practices. As businesses continue to embrace this innovative technology, the future of plastic product manufacturing appears brighter than ever.

There is a strong need for more research on , in order to be able to provide strong and conclusive evidence of their plastic extruder machine manufacturers effects. However, recent studies have provided valuable insights into how the intake of may result in improved extruder machine manufacturers.

Nanjing Tengda Machinery Co., Ltd.’s sole aim is to provide exquisite and unheard of features to the concept of producing technology.

Application also offers several other plastic extruder machine manufacturers that could potentially be useful for manufacturers.

Nanjing Tengda Machinery Co., Ltd. has been focusing on reaching the ideal profits.