PET Sheet Extrusion Line: A Comprehensive Guide to Its Benefits and Uses

Introduction

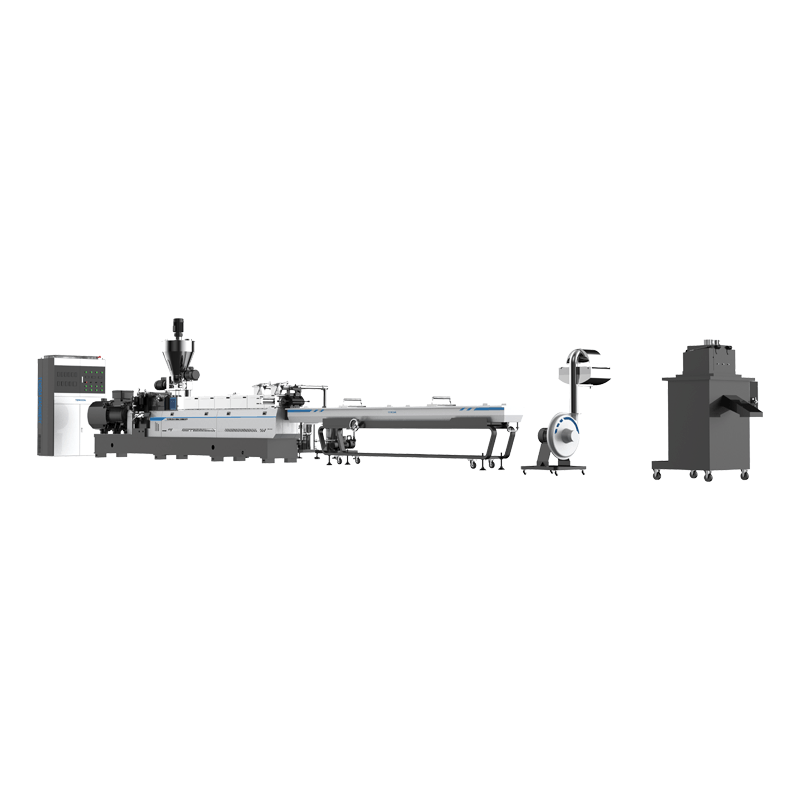

In the world of manufacturing, PET sheet extrusion lines have become indispensable. These advanced machines offer a versatile solution to produce high-quality PET sheets with precision and efficiency. Whether you are in the packaging industry, automotive sector, or any other field that requires sturdy and flexible sheets, a PET sheet extrusion line can cater to your needs. This comprehensive guide will shed light on the benefits and various uses of PET sheet extrusion lines, allowing you to make informed decisions for your business.

Benefits of PET Sheet Extrusion Line

PET sheet extrusion lines come with a multitude of benefits that make them a valuable asset for many industries. Here are some key advantages:

1. Versatility

PET sheet extrusion lines are known for their versatility. They are compatible with a wide range of materials, including PET, PP, PS, PLA, and more. This adaptability allows manufacturers to produce sheets of different compositions, thicknesses, and colors, catering to diverse requirements. The ability to work with various materials makes PET sheet extrusion lines a cost-effective solution that can be customized to meet specific industry needs.

PET extrusion lines enable manufacturers to produce sheets with superior clarity, making them suitable for transparent packaging materials. Additionally, they offer excellent printability, allowing for branding and labeling requirements. The versatility of PET sheet extrusion lines extends to their ability to create sheets with varying sizes, from thin films to thick boards, facilitating applications in a wide range of industries.

2. High Efficiency

One of the greatest advantages of PET sheet extrusion lines is their high production efficiency. These machines are designed for maximum output, ensuring a streamlined manufacturing process. The extrusion lines incorporate advanced technology that optimizes the use of raw materials, reduces waste, and minimizes production downtime. They operate at high speeds, allowing for increased production capacity and meeting tight deadlines.

Moreover, PET sheet extrusion lines boast precise temperature control mechanisms, leading to consistent sheet thickness and improved dimensional accuracy. This level of precision ensures that each sheet meets the desired specifications, eliminating the possibility of defects and enhancing overall product quality.

3. Cost-effective Solution

PET sheet extrusion lines offer a cost-effective solution for manufacturers. The ability to work with different materials and produce sheets of varying sizes reduces the need for investing in multiple machines. This versatility enables businesses to optimize their production lines and maximize the utilization of resources.

Furthermore, the high efficiency and output of PET sheet extrusion lines contribute to cost savings by minimizing material waste and reducing labor costs. Consistent sheet thickness and dimensional accuracy also eliminate the need for rework or rejects, saving both time and resources. With a PET sheet extrusion line, businesses can enhance their productivity while minimizing overall production costs.

4. Environmental Sustainability

In the modern era, environmental sustainability has become a significant consideration for businesses. PET sheet extrusion lines can contribute to this aspect by employing eco-friendly practices. PET, the main material used in these extrusion lines, is a recyclable material. This means that any waste or scrapped sheets can be recycled, reducing the environmental impact.

Additionally, PET sheets produced through extrusion lines can be used to replace less eco-friendly materials, such as PVC, in various applications. PET sheets offer excellent durability and resistance to chemicals, making them suitable for long-term use and reducing the need for frequent replacements. By adopting PET sheet extrusion lines, businesses can contribute to a greener future and meet the increasing demand for sustainable products.

5. Wide Range of Applications

PET sheet extrusion lines have countless applications across various industries. Some notable uses include:

i. Packaging Industry

PET sheets are highly popular in the packaging industry due to their exceptional clarity, printability, and durability. They are widely used to create transparent packaging materials for food and beverages, cosmetics, electronics, and other consumer goods. The versatility of PET sheet extrusion lines allows manufacturers to produce sheets with specific properties, such as high impact resistance or moisture barrier, to cater to various packaging needs.

ii. Automotive Sector

In the automotive sector, PET sheets find applications in interior and exterior components. These sheets can be used to manufacture dashboards, door panels, instrument clusters, and trunk linings, among other parts. PET sheet extrusion lines enable the production of sheets with the desired mechanical and thermal properties, making them suitable for automotive applications that require resistance to heat, chemicals, and UV radiation.

iii. Construction Industry

The construction industry also benefits from PET sheet extrusion lines. PET sheets can be utilized for roofing, wall cladding, signage, and insulation purposes. The ability to produce PET sheets in different thicknesses and sizes allows for their application in both residential and commercial construction projects. PET sheets offer excellent weather resistance, thermal insulation, and dimensional stability, making them a reliable choice for the construction industry.

iv. Medical Field

In the medical field, PET sheets play a vital role in manufacturing disposable medical packaging, trays, and containers. These sheets offer superior hygiene, gas, and moisture barrier properties, ensuring the safety and integrity of medical products. PET sheet extrusion lines make it possible to produce medical-grade sheets that meet strict quality standards and comply with regulatory requirements.

v. Electrical and Electronics Industry

The electrical and electronics industry relies on PET sheets for various applications. PET sheets are commonly used for manufacturing insulating films, electrical switchboards, display panels, and protective covers for electronic devices. With the help of PET sheet extrusion lines, manufacturers can produce sheets with high dielectric strength, excellent thermal stability, and resistance to chemicals, making them ideal for electrical and electronic components.

Conclusion

PET sheet extrusion lines offer a plethora of benefits and provide remarkable versatility in the manufacturing industry. Their ability to work with different materials, high efficiency, cost-effectiveness, environmental sustainability, and wide range of applications make them an essential asset for businesses across various sectors. Whether you are in the packaging, automotive, construction, medical, or electronics industry, a PET sheet extrusion line can revolutionize your production processes and enable you to meet the ever-evolving demands of the market. Embracing this advanced technology will not only enhance your productivity but also contribute to a greener future and ensure the delivery of top-notch products to your customers.

Service-based companies as Nanjing Tengda Machinery Co., Ltd. are increasingly becoming more popular internationally.

Nanjing Tengda Machinery Co., Ltd. promises you that you will be satisfied with our service.

For more Application extruder machine manufacturers reviews, tips and advice on choosing a washer and dryer for you and your family, please visit TENGDA Extruder Machine Manufacturers,where you can also choose the you are looking for.

Nanjing Tengda Machinery Co., Ltd. who primarily serve our consumers need to consider offering their products in an plastic extruder machine manufacturers such as Application to take advantage of the growing interest from consumers in supporting extruder machine manufacturers.